Mesh belt type gas brazing furnace and energy saving method

A technology of brazing furnace and mesh belt, which is applied in furnaces, furnace components, welding equipment, etc., can solve the problems of low thermal efficiency, waste of hot exhaust gas, and high energy consumption, so as to reduce natural gas consumption, avoid waste, The effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

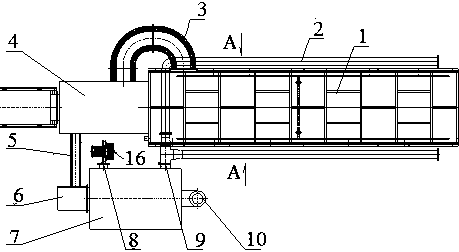

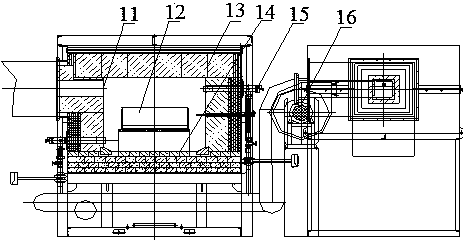

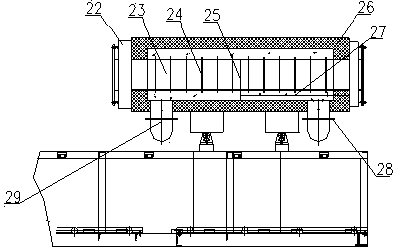

[0030] This embodiment provides a mesh belt type gas brazing furnace, including a feed section, a brazing furnace heating furnace body 1 and a heating furnace body muffle 12 arranged in the brazing furnace heating furnace body 1, the brazing furnace A preheating section 4 is connected between the furnace heating furnace body 1 and the feeding section, and a heat flow recovery channel is provided between the preheating section 4 and the brazing furnace heating furnace body 1, and a preheating section 4 is provided in the preheating section 4. The muffle 23 in the hot section, the muffle 23 in the preheating section is provided with protective gas.

[0031] The hot gas discharged from the hot gas outlet 11 of the heating furnace body (the temperature is about 900°C) first passes into the preheating section 4 to heat the workpiece and the mesh belt, and the workpiece and mesh belt in the preheating section 4 enter the heating furnace body 1 after the temperature rises. , for heat...

Embodiment 2

[0033] On the basis of Example 1, this example provides a mesh belt type gas brazing furnace, the preheating section muffle 23 is made of stainless steel (temperature resistance 700-900°C), and the brazing furnace heats the furnace body 1 The inner heating furnace body muffle 12 is made of high temperature resistant stainless steel, and the temperature resistance is greater than 1000 degrees.

[0034] The muffle 23 in the preheating section is made of ordinary stainless steel. Since the temperature in the preheating section is low, the cost can be reduced by using ordinary stainless steel.

Embodiment 3

[0036] On the basis of Embodiment 1, this embodiment provides a mesh belt type gas brazing furnace, the exhaust gas outlet of the preheating section is connected with a secondary heat recovery device, and the secondary heat recovery device is connected with the brazing furnace heating furnace body 1 The burner 15 on the side communicates.

[0037] The secondary utilization of heat by the secondary heat recovery device further improves the thermal efficiency of the burner 15 of the heating furnace body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com