Steel pipe machining system with automatic coding function

一种加工系统、自动打码的技术,应用在金属加工、制造工具、其他制造设备/工具等方向,能够解决不能解决打码、传输、加工过程描述等问题,达到冷却效果好、便于调整、减少热应力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

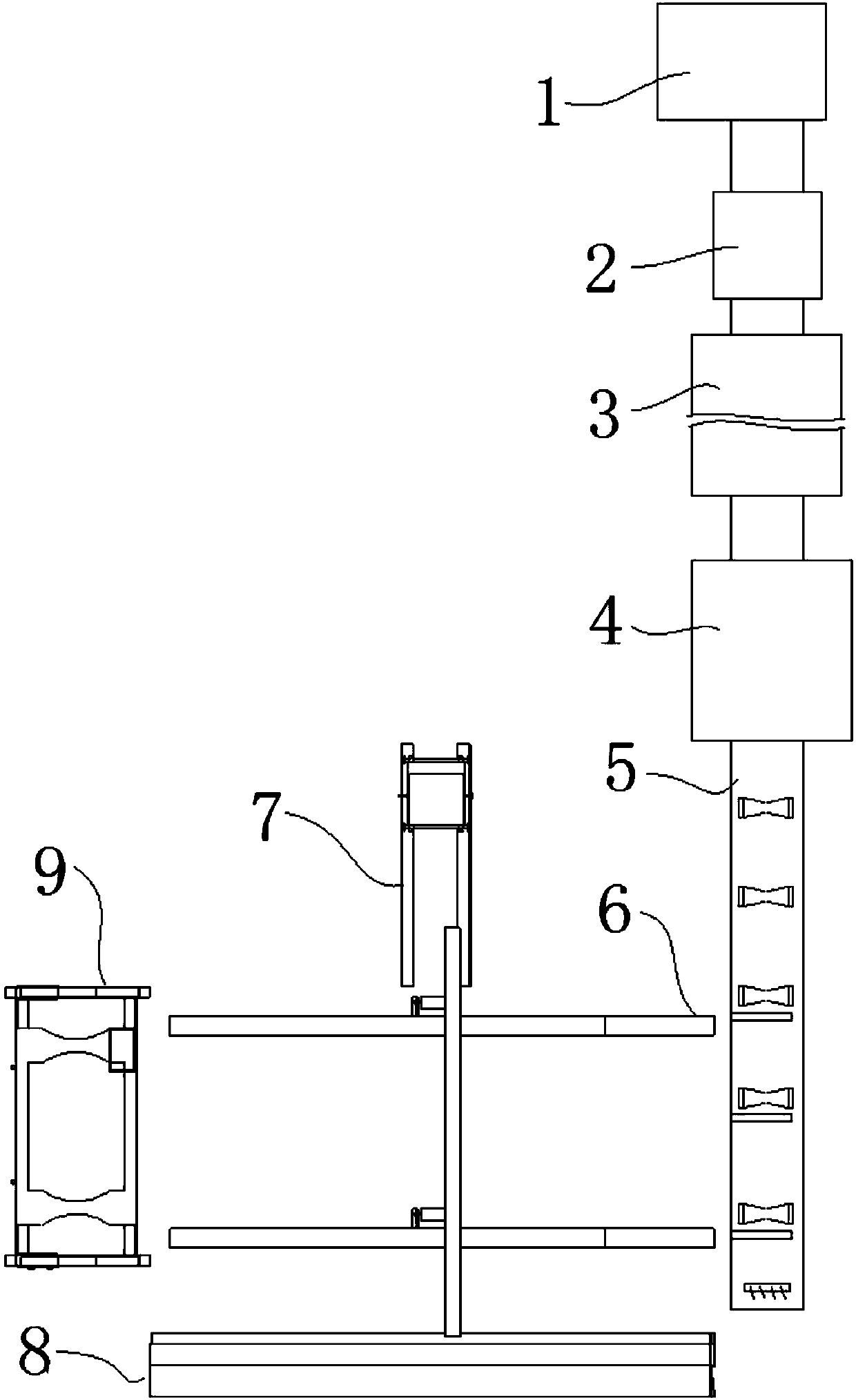

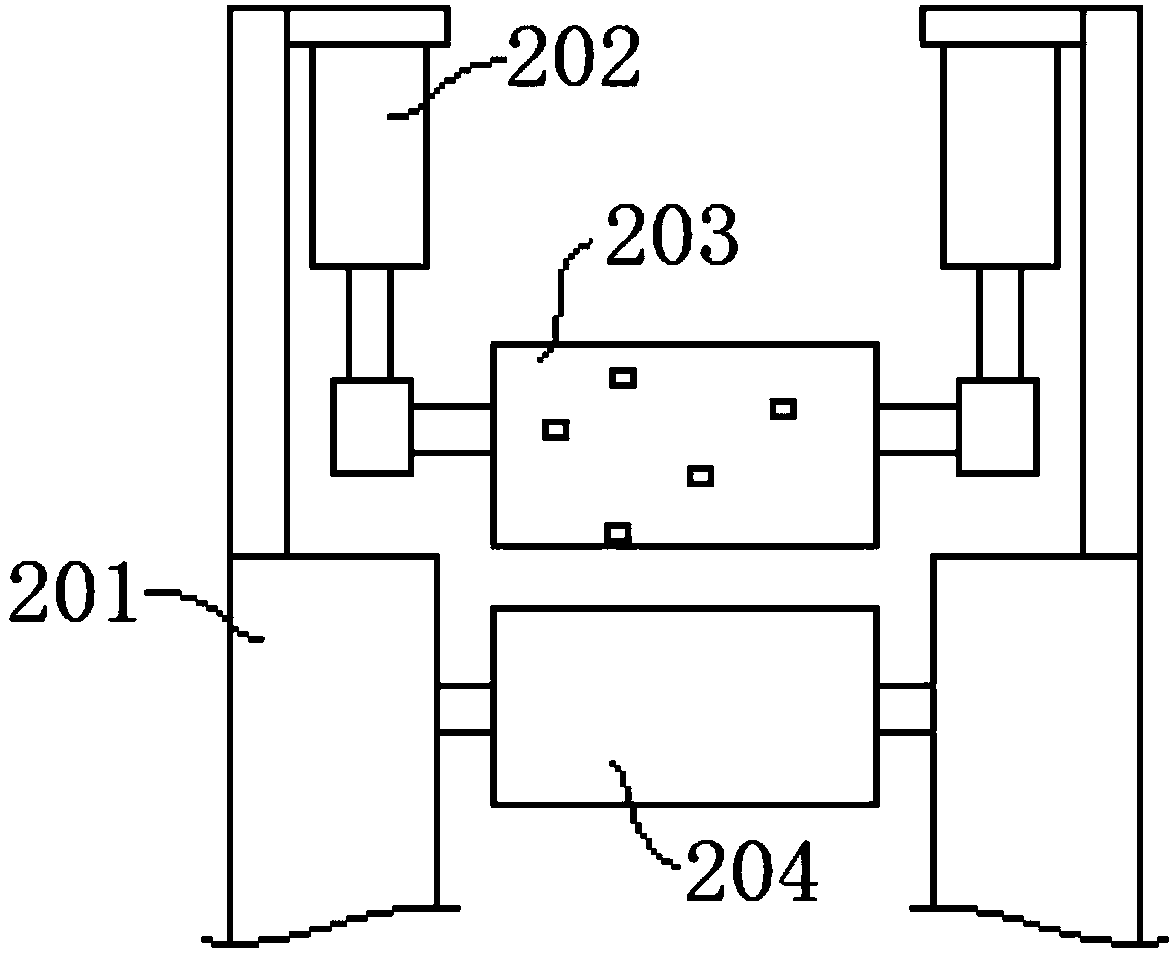

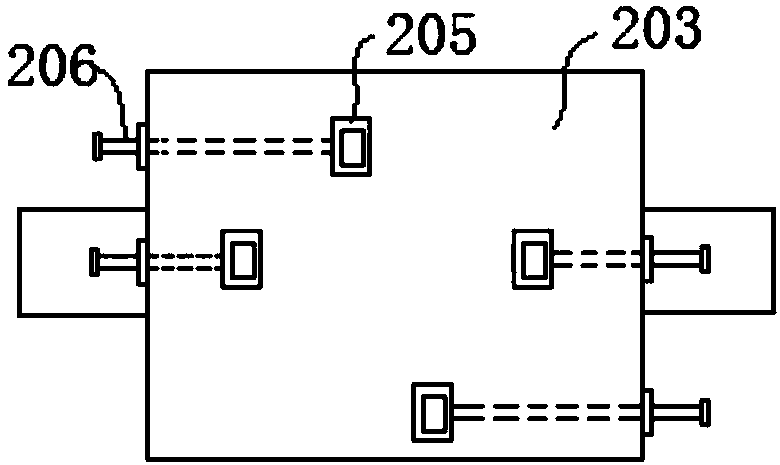

[0049] combine figure 1 , a steel pipe processing system that can automatically code in this embodiment includes an unwinding mechanism 1, a welding mechanism 3, a cutting mechanism 4, a transmission mechanism 5, a coding mechanism 2, an unloading mechanism 6, a chamfering mechanism 7 and Transporter 9, wherein unwinding mechanism 1, roll welding mechanism 3 and cutting mechanism 4 can adopt conventional design. The unwinding mechanism 1 flattens the coiled sheet and sends it to the rolling and welding mechanism 3 after being coded by the coding mechanism 2. The welded steel pipe is cut into a fixed length by the cutting mechanism 4 and enters the transmission mechanism 5. The unloading mechanism 6 Cooperate with the transmission mechanism 5, and set a chamfering mechanism 7 on one side of the unloading mechanism 6, and set a transport vehicle 9 at the tail end of the unloading mechanism 6, and bundle and transport the steel pipes on the transport vehicle 9 after chamfering. ...

Embodiment 2

[0062] to combine Figure 11 , a steel pipe processing system that can automatically print codes in this embodiment, its basic structure is the same as that of Embodiment 1, the difference is that the drainage tank 8 in this embodiment is mainly composed of a water tank bottom plate 801, a left baffle plate 802 and Right baffle plate 803 is formed, and described left baffle plate 802 and right baffle plate 803 are inclined to the both sides of sink bottom plate 801 respectively, and left baffle plate 802 height is less than right baffle plate 803 height; The angle and direction of inclination are the same as those of the right support frame 602 respectively, and the high position end of the drainage groove 8 is in a closed state. The right baffle plate 803 is higher to prevent the outflowing water from splashing out, and the tank bottom plate 801 provided with an inclination makes the cooling water flow to the lower end automatically, and can be recycled after entering the fil...

Embodiment 3

[0065] A steel pipe processing system that can automatically print codes in this embodiment has the same basic structure as that of Embodiment 2, the difference being that a fixed block 6032 is arranged on the horizontal plate of the right-angle support plate 6031 in this embodiment, and the transmission The roller connecting rod 6034 is provided with a threaded hole, and a supporting bolt 6033 is threaded in the threaded hole, and the lower end of the supporting bolt 6033 is inserted into the round hole in the middle of the fixing block 6032 . This structural design facilitates the adjustment of the height of the steel pipe, cooperates with the chamfering mechanism 7, and is suitable for chamfering processing of steel pipes with different pipe diameters.

[0066] In the present invention, various mechanisms cooperate with each other to form a complete steel pipe processing system, which has better effects on coding, engraving and cooling treatment of steel pipes, and the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com