Device and method for solution casting large film

A membrane device and solution technology, which is applied in the field of solution casting large membrane devices, can solve the problems of fast evaporation of casting liquid, slow evaporation of casting liquid, and non-parallel heating devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment is made of 100cm×100cm×0.076mm perfluorinated ion exchange membrane, including the following steps:

[0048] 1) Add 0.2kg of perfluorosulfonic acid ion exchange resin with equivalent weight EW=1000g / eq and 4L of dimethylformamide (boiling point 153°C) into a 6L closed reactor, heat and stir to dissolve, the dissolution temperature is 200°C, and the dissolution time is 4 hours , the perfluorosulfonic acid ion exchange resin was dissolved in dimethylformamide to prepare about 4L of a casting solution with a concentration of 5%.

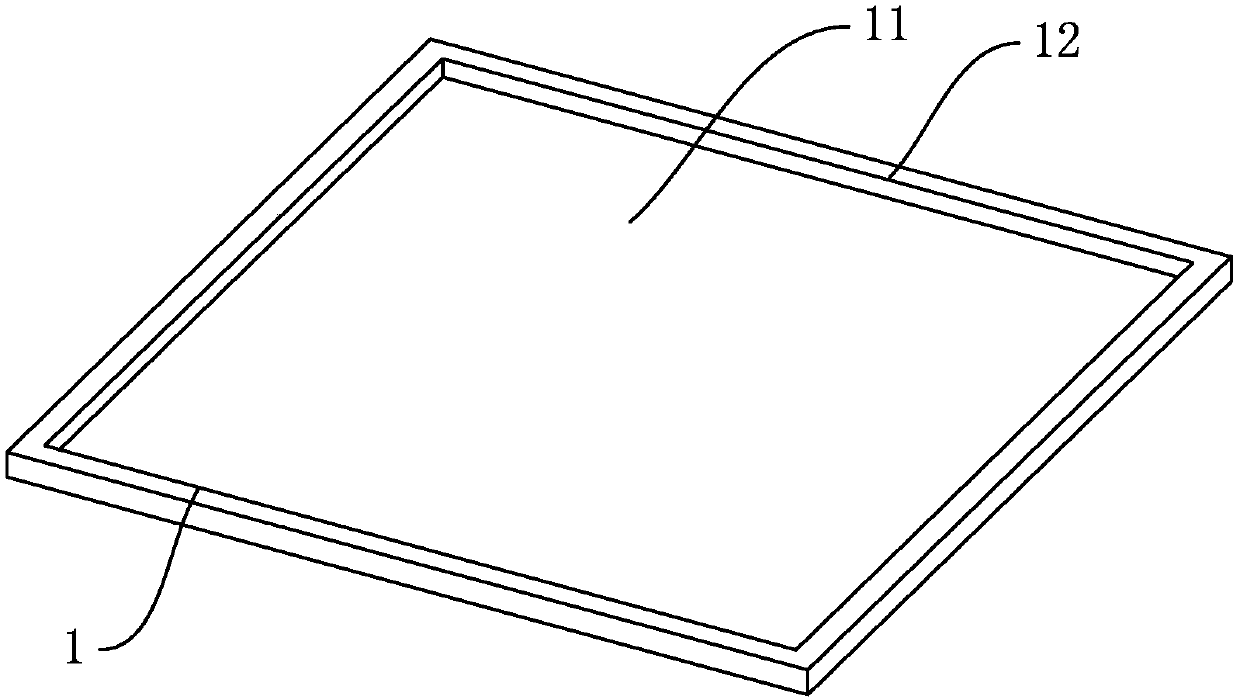

[0049] 2) Use float glass and glass glue to prepare a cast film disc 1 with an area of 110cm×110cm, a thickness of 2cm, a depth of 1cm, a side width of 3cm, and an inner bottom area of 104cm×104cm. figure 1 shown.

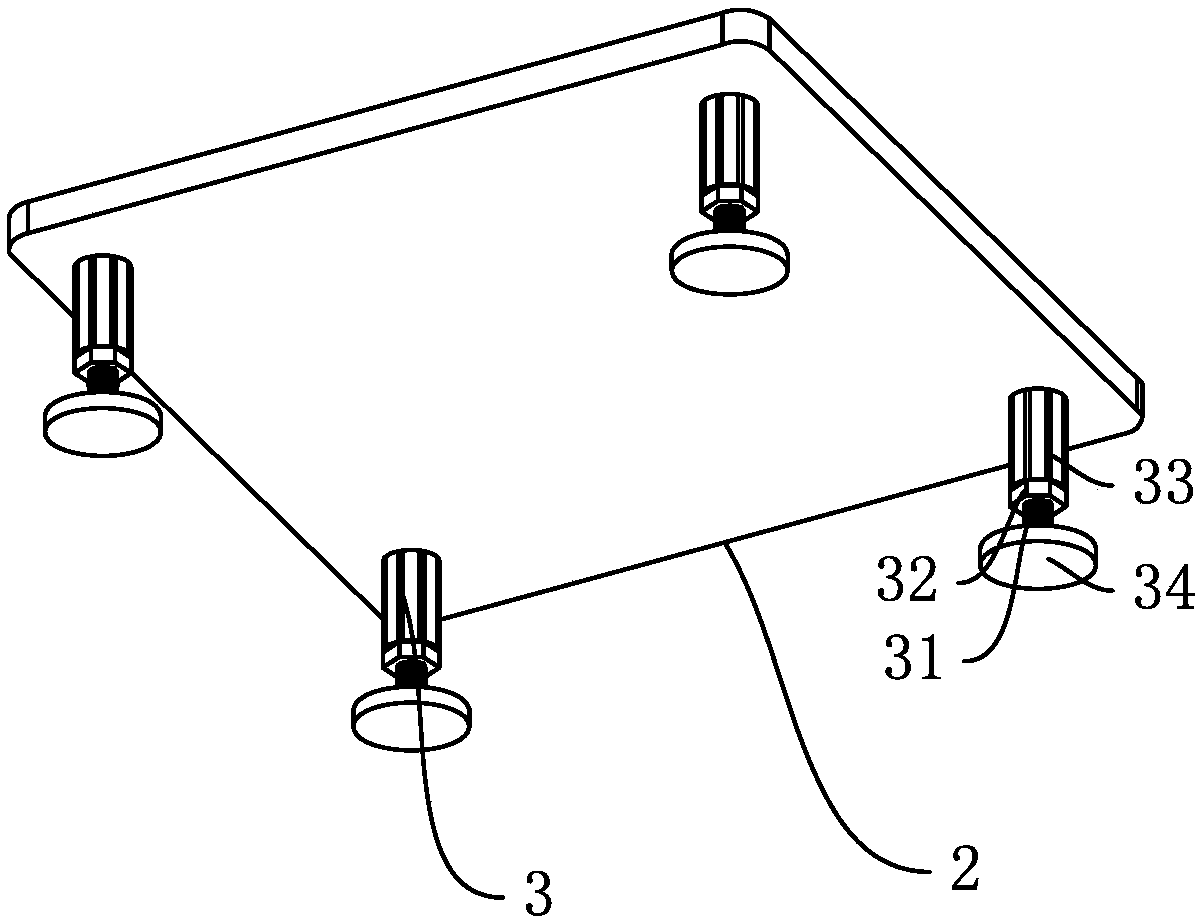

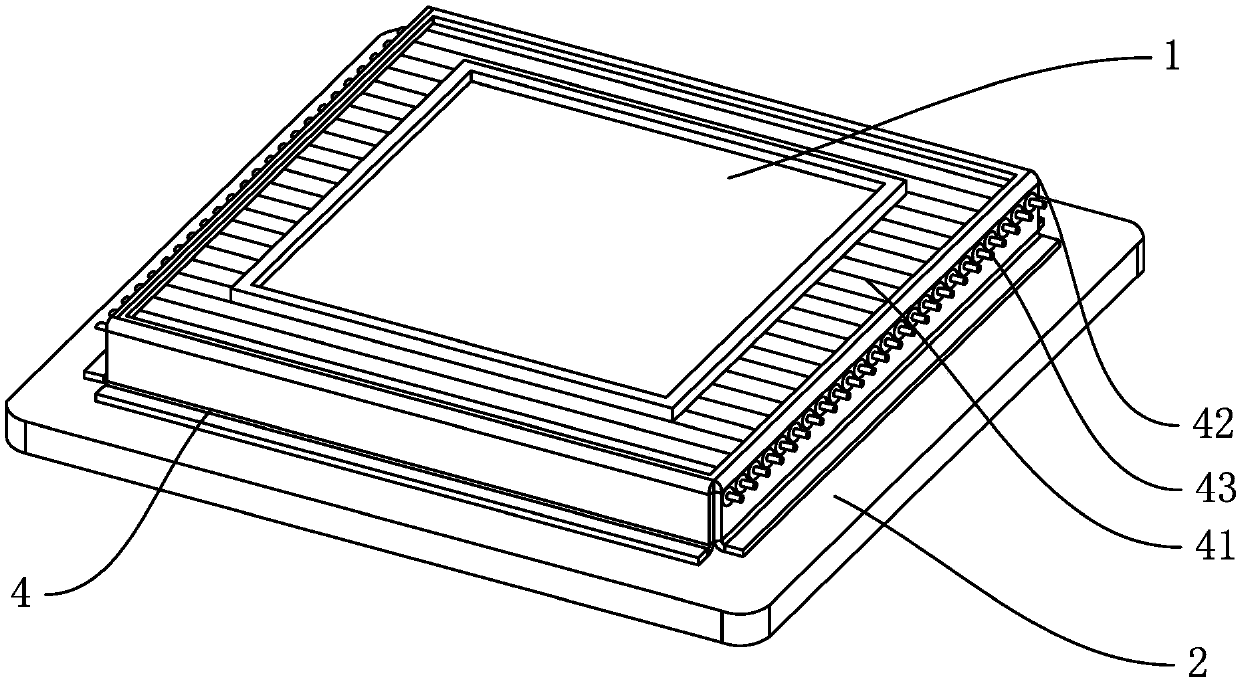

[0050] 3) Prepare a 150cm×150cm×5cm heat preservation base plate 2 with 1mm stainless steel plate sandwiched with asbestos plate, and set adjustment feet 3 at the four corners below the heat preservation base plat...

Embodiment 2

[0064] This embodiment is made of 150cm×150cm×0.127mm perfluorinated ion exchange membrane, including the following steps:

[0065] 1) Add 10kg of perfluorosulfonic acid ion exchange resin with equivalent weight EW=1000g / eq and 200L dimethylformamide (boiling point 153°C) into a 300L closed reactor, heat and stir to dissolve, the dissolution temperature is 210°C, and the dissolution time is 5 hours. The perfluorosulfonic acid ion exchange resin was dissolved in dimethylformamide to prepare about 200 L of casting solution with a concentration of 5%.

[0066] 2) Use float glass and glass glue to prepare a cast film disk 1 with an area of 160cm×160cm, a thickness of 2cm, a depth of 1cm, a side width of 3cm, and an inner bottom area of 154cm×154cm. figure 1 shown.

[0067] 3) Prepare a 210cm×210cm×5cm heat preservation bottom plate 2 with 1mm stainless steel plate sandwiched with asbestos board, and set adjustment feet 3 at the four corners below the heat preservation bottom ...

Embodiment 3

[0081] This embodiment is made of 200cm×200cm×0.178mm perfluorinated ion exchange membrane, including the following steps:

[0082] 1) Add 20kg of perfluorosulfonic acid ion exchange resin with equivalent weight EW=1000g / eq and 400L dimethylformamide (boiling point 153°C) into a 600L closed reactor and heat and stir to dissolve. The dissolution temperature is 200°C and the dissolution time is 6 hours. The perfluorosulfonic acid ion exchange resin was dissolved in dimethylformamide to prepare about 400 L of casting solution with a concentration of 5%.

[0083] 2) Use float glass and glass glue to prepare a cast film disk 1 with an area of 210cm×210cm, a thickness of 2cm, a depth of 1cm, a side width of 3cm, and an inner bottom area of 204cm×204cm. figure 1 shown.

[0084] 3) Prepare a 300cm×300cm×5cm heat preservation base plate 2 with 1mm stainless steel plate sandwiched with asbestos plate, and set adjustment feet 3 at the four corners below the heat preservation base pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com