Preparation method of anti-algae room temperature vulcanized silicone rubber (RTV)

A technology of silicone rubber and silicon dioxide, which is applied in the field of preparation of anti-algae RTV silicone rubber, can solve the problems of growing algae, destroying the hydrophobicity of the material surface, reducing the reliability of insulation, etc., achieving low cost, preventing microbial growth, and ensuring safety running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

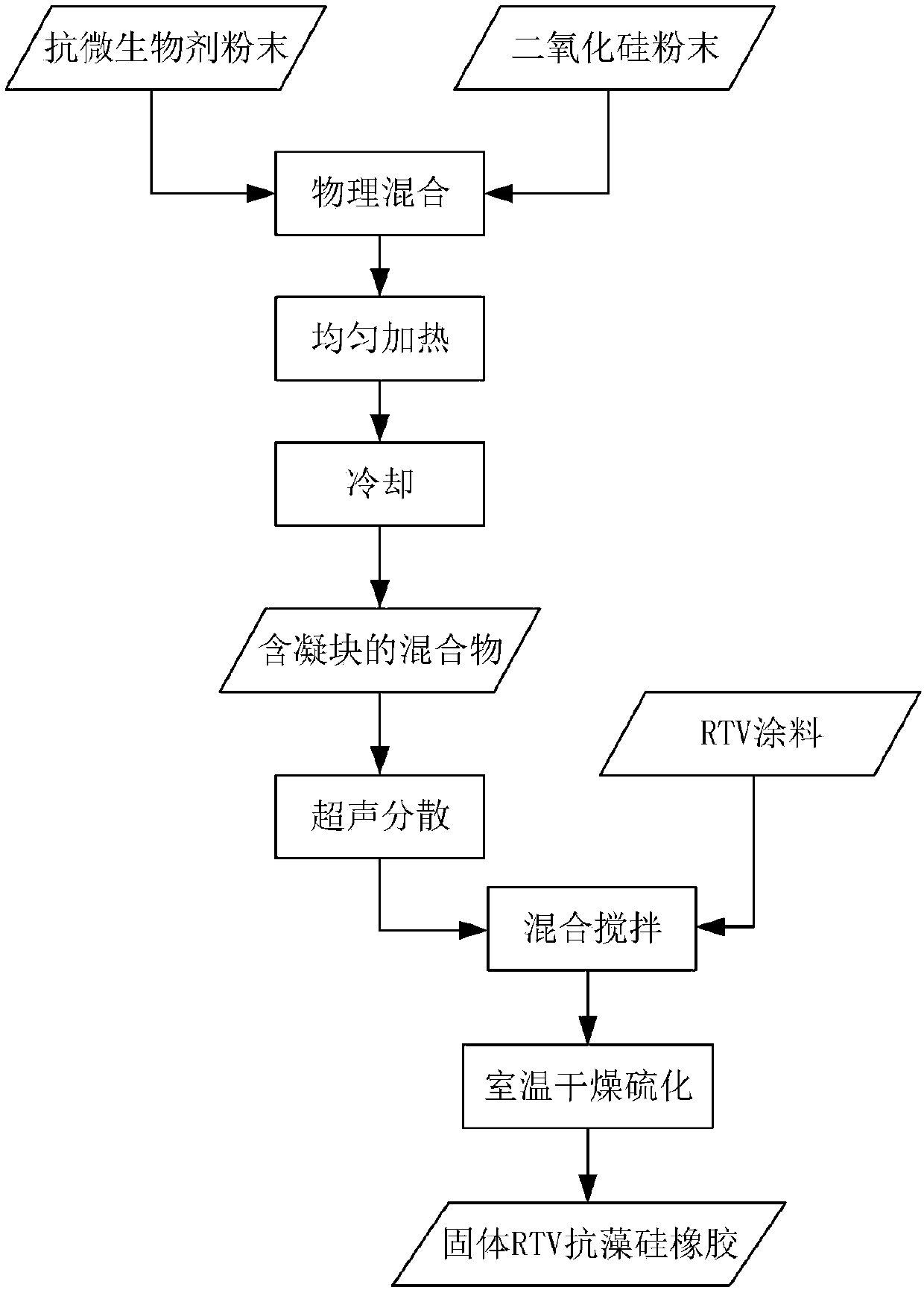

[0030] The specific embodiment of the present invention proposes a kind of preparation method of anti-algae RTV silicone rubber, as figure 1 As shown, the preparation method comprises the following steps S1 to S4:

[0031] S1. Weigh a certain mass of antimicrobial agent powder and silicon dioxide powder according to the required mass ratio and physically mix them to obtain a powdery mixture;

[0032] S2. Put the powdery mixture into an airtight container and heat it evenly, start timing when the heating temperature reaches the melting point of the antimicrobial agent, and stop heating after at least 30 minutes;

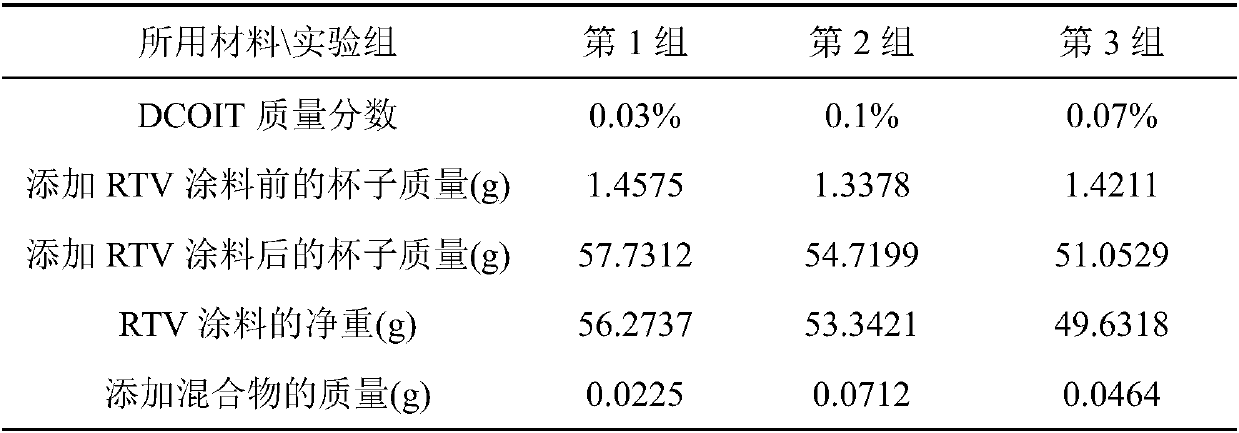

[0033] S3. After the mixture is cooled to room temperature, a mixture containing clots is obtained; then the mixture containing clots is dispersed, and a predetermined mass of the dispersed mixture is weighed according to a given mass fraction of antimicrobial agent, and added to RTV paint, then stir;

[0034] S4. Dry and vulcanize the RTV coating added with the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com