Device and method for improving anaerobic methanogenesis of kitchen garbage

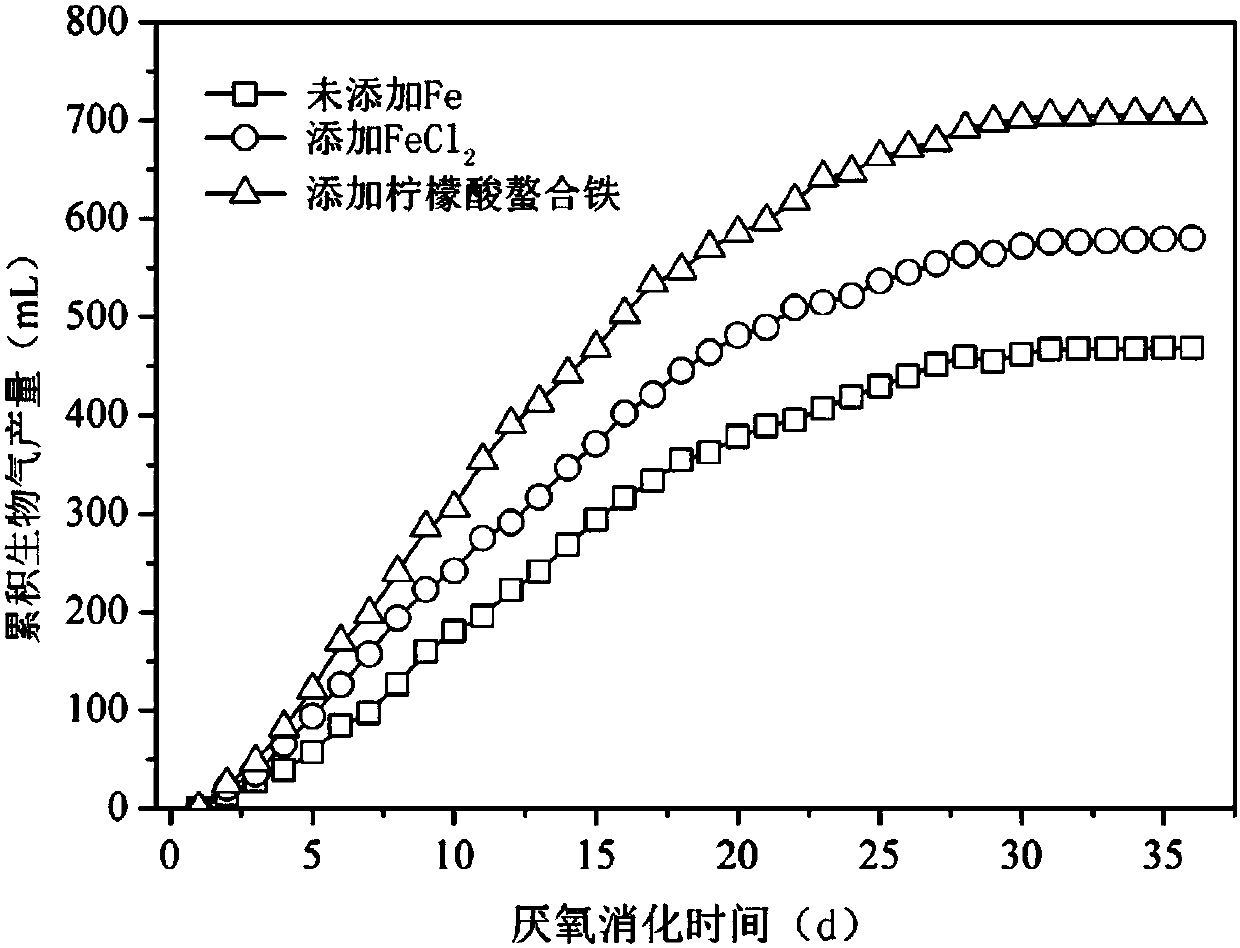

A technology for anaerobic methane production and kitchen waste, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve the problem of low biogas production and methane content, and high content of easily degradable organic matter , limit the growth of methanogenic bacteria and other issues, achieve the effect of increasing methane production rate and content, realizing resource utilization, and important promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

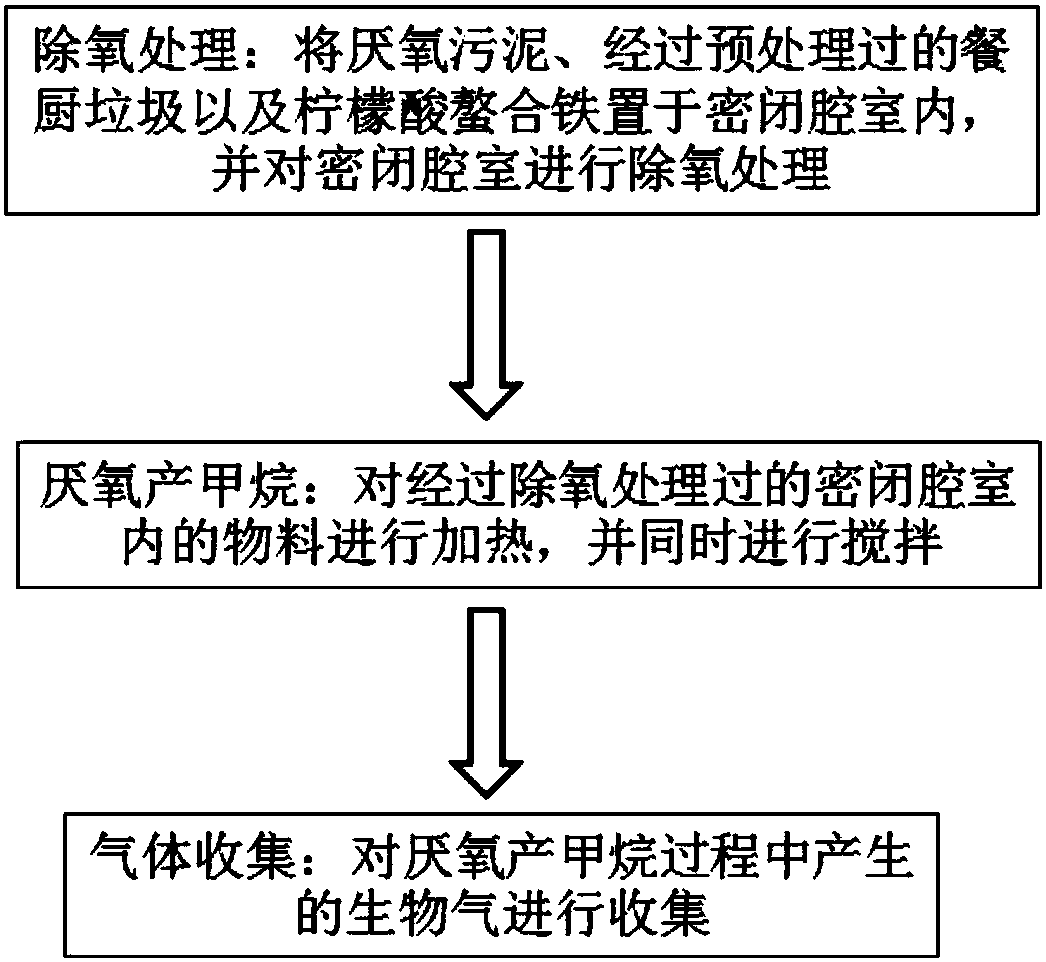

[0052] This embodiment provides a method for improving anaerobic methanogenesis of kitchen waste, which is implemented in the above-mentioned device 100 for improving anaerobic methanogenesis of kitchen waste, and specifically includes the following steps:

[0053] Wash the collected food waste with tap water, then manually pick out the bones, plastic products, paper towels and other sundries in the food waste, and finally, smash the food waste to 2-3mm.

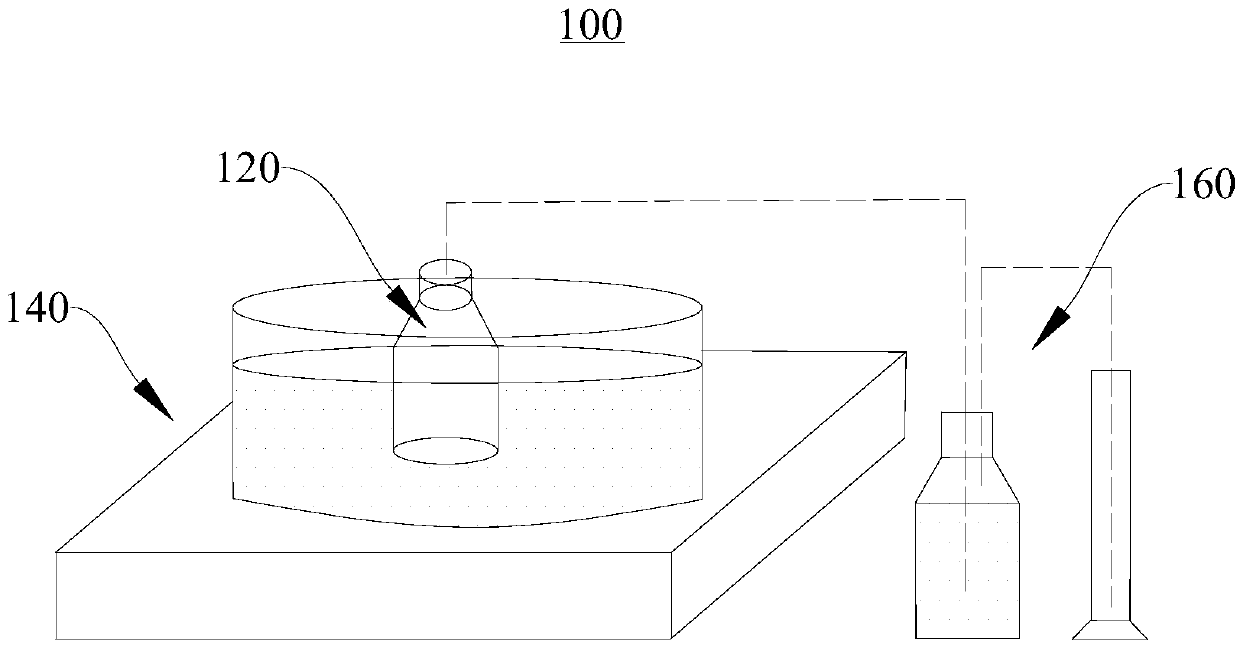

[0054] Clean the anaerobic bottle 120 with a volume of 500mL, and put 200mL of kitchen waste and 50mL of anaerobic sludge in the initial stage of the anaerobic bottle 120, and then calculate according to the Fe dosage of 0.11mg / gVS, The amount of citric acid chelated iron to be added is 0.65 mg / gVS, and then nitrogen is passed through the anaerobic bottle 120 for 10 minutes, and then sealed with a rubber stopper.

[0055] The material in the anaerobic bottle 120 is heated and stirred with a magnetic stirrer 140. The heating ...

Embodiment 2

[0057] This embodiment provides a method for improving anaerobic methanogenesis of kitchen waste, which is implemented in the above-mentioned device 100 for improving anaerobic methanogenesis of kitchen waste, and specifically includes the following steps:

[0058] Wash the collected food waste with tap water, then manually pick out the bones, plastic products, paper towels and other sundries in the food waste, and finally, smash the food waste to 2-3mm.

[0059] Clean the anaerobic bottle 120 with a volume of 500mL, and put 200mL of kitchen waste and 50mL of anaerobic sludge in the initial stage of the anaerobic bottle 120, and then add citric acid chelation according to the dosage of 0.66mg / gVS iron, and then pass nitrogen in the anaerobic bottle 120 for 12 minutes, and then seal it with a rubber stopper.

[0060] The material in the anaerobic bottle 120 is heated and stirred with a magnetic stirrer 140. The heating temperature of the water bath is 35.5° C., and the rotation...

Embodiment 3

[0062] This embodiment provides a method for improving anaerobic methanogenesis of kitchen waste, which is implemented in the above-mentioned device 100 for improving anaerobic methanogenesis of kitchen waste, and specifically includes the following steps:

[0063] Wash the collected food waste with tap water, then manually pick out the bones, plastic products, paper towels and other sundries in the food waste, and finally, smash the food waste to 2-3mm.

[0064] Clean the anaerobic bottle 120 with a volume of 500mL, and put 200mL of kitchen waste and 50mL of anaerobic sludge in the initial stage of the anaerobic bottle 120, and then add citric acid chelation according to the dosage of 0.64mg / gVS iron, and then pass nitrogen gas in the anaerobic bottle 120 for 8 minutes, and then seal it with a rubber stopper.

[0065] The material in the anaerobic bottle 120 is heated and stirred with a magnetic stirrer 140, the heating temperature of the water bath is 34.5°C, and the rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com