Positioning device capable of performing grouting connection of reinforcing steel bars and metal corrugated pipes in batch manner

A metal bellows and positioning device technology, applied in the field of construction, can solve the problems of delaying the test process, time-consuming and laborious, etc., achieving the effects of convenient construction, improving test efficiency, and reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

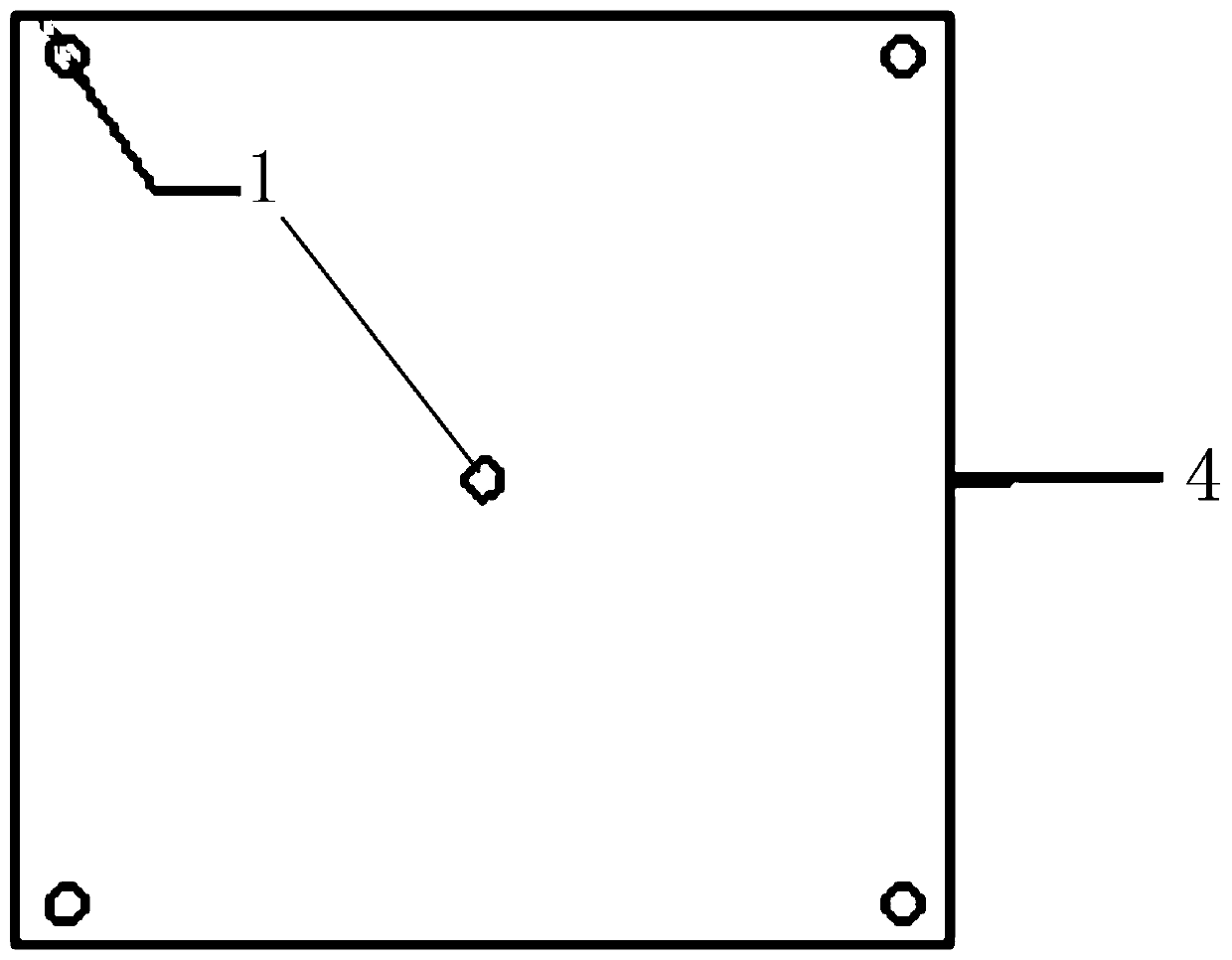

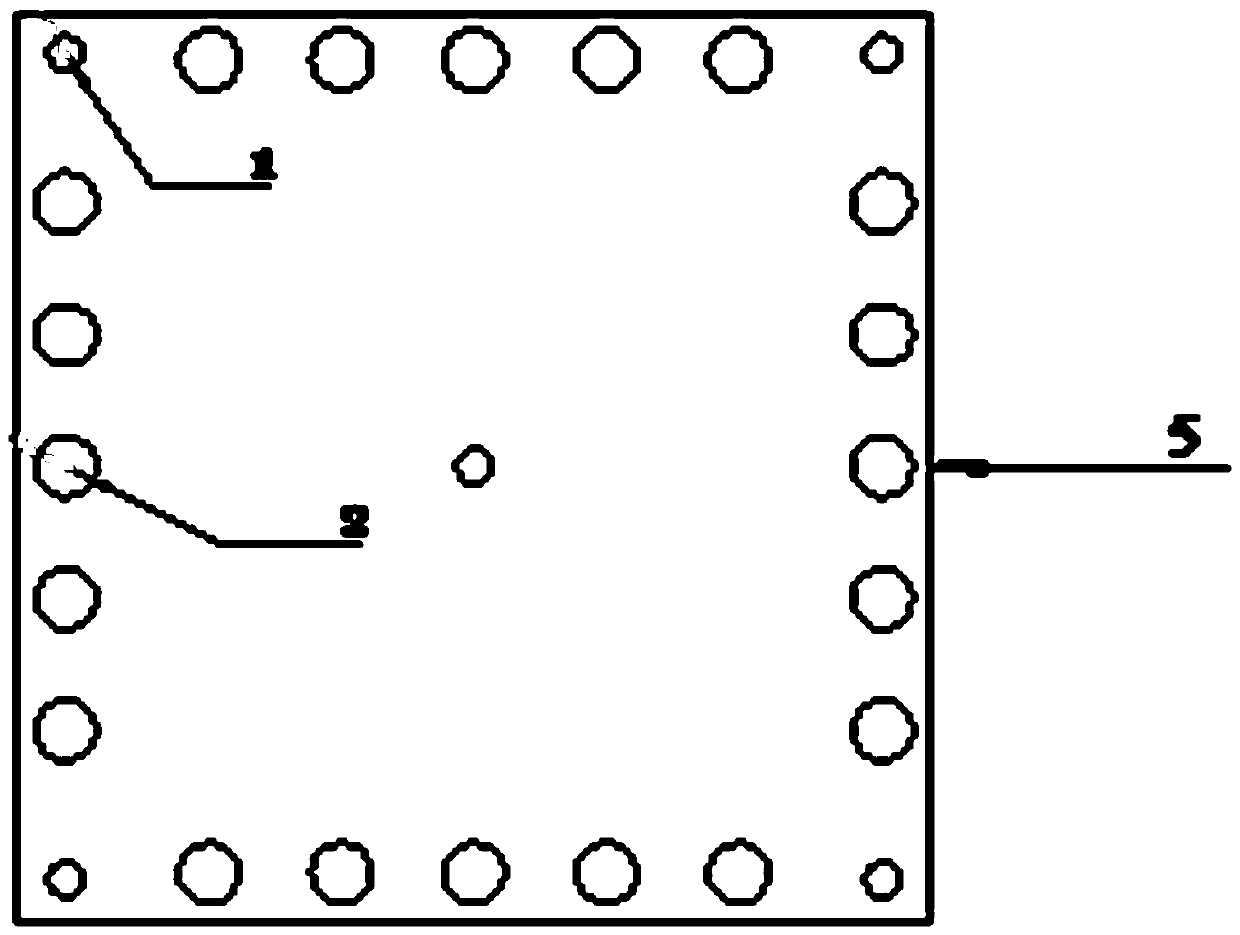

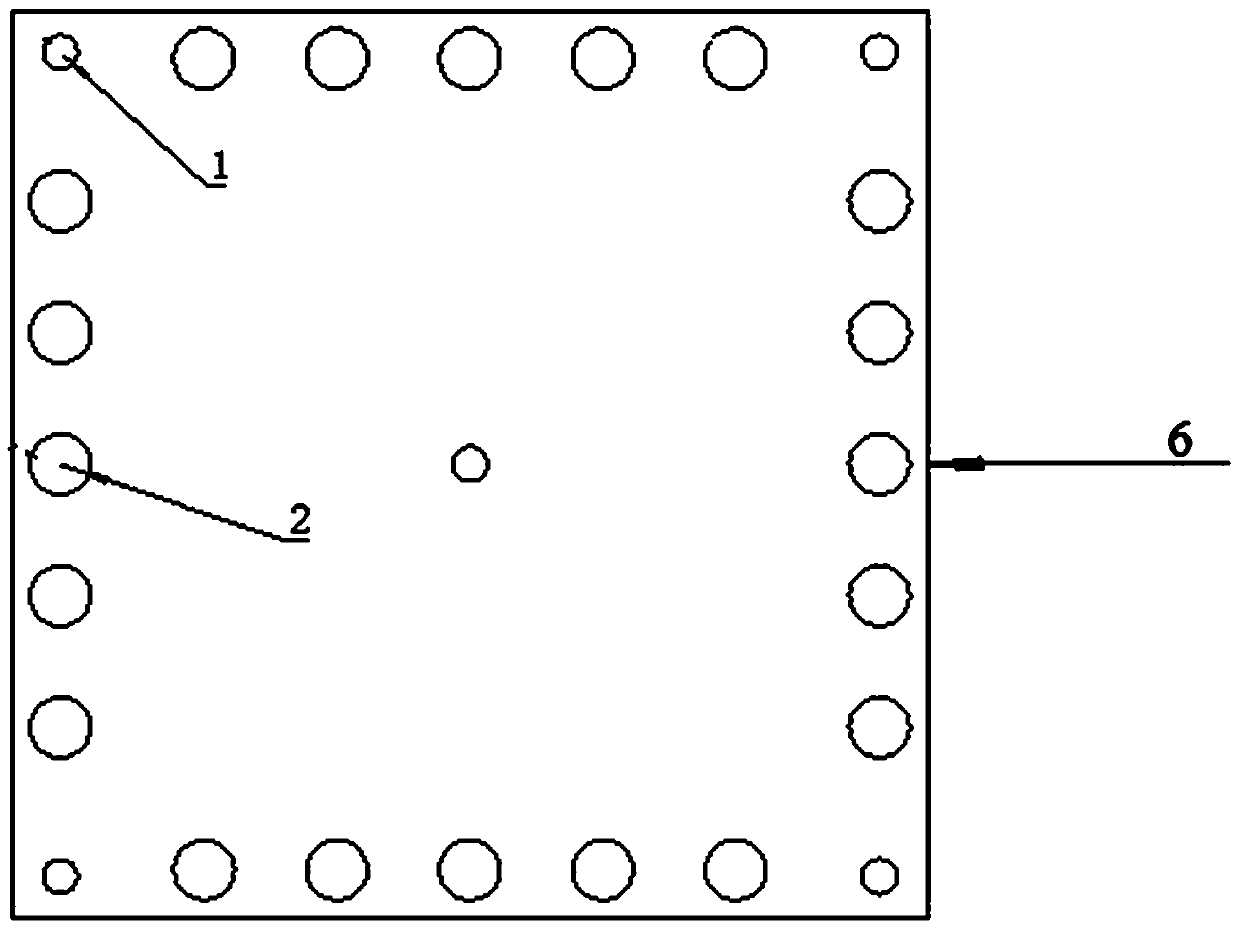

[0037] like Figure 1-6 As shown, a positioning device that can perform grouting connection of steel bars and metal corrugated pipes in batches, the positioning device includes a corrugated pipe positioning system and a steel bar positioning system; the corrugated pipe positioning system includes a corrugated pipe positioning seat 14, a pipe body positioning plate 6 and a plurality of screws 13; the upper end face of the positioning seat 14 is a horizontal plane; the screw rods are vertically arranged at the corrugated tube positioning seat, and the screw rod 13 supports the positioning plate 6 of the pipe body so that it can be suspended in parallel above the upper end surface of the positioning seat 14; The bellows positioning seat is provided with a number of pipe end positioning blind holes, and the pipe body positioning plate is provided with pipe body positioning holes 2 corresponding to the pipe end positioning blind holes; the pipe body positioning holes 2 and the pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com