Hf<x>Si<1-x>O2 multi-component oxide storage material-based charge storage device and fabrication method thereof

A technology of charge storage and storage materials, which is applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of increased leakage current, low charge storage density, and reduced thickness, so as to reduce the probability of electron leakage, Effect of improving charge retention ability and reducing charge loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

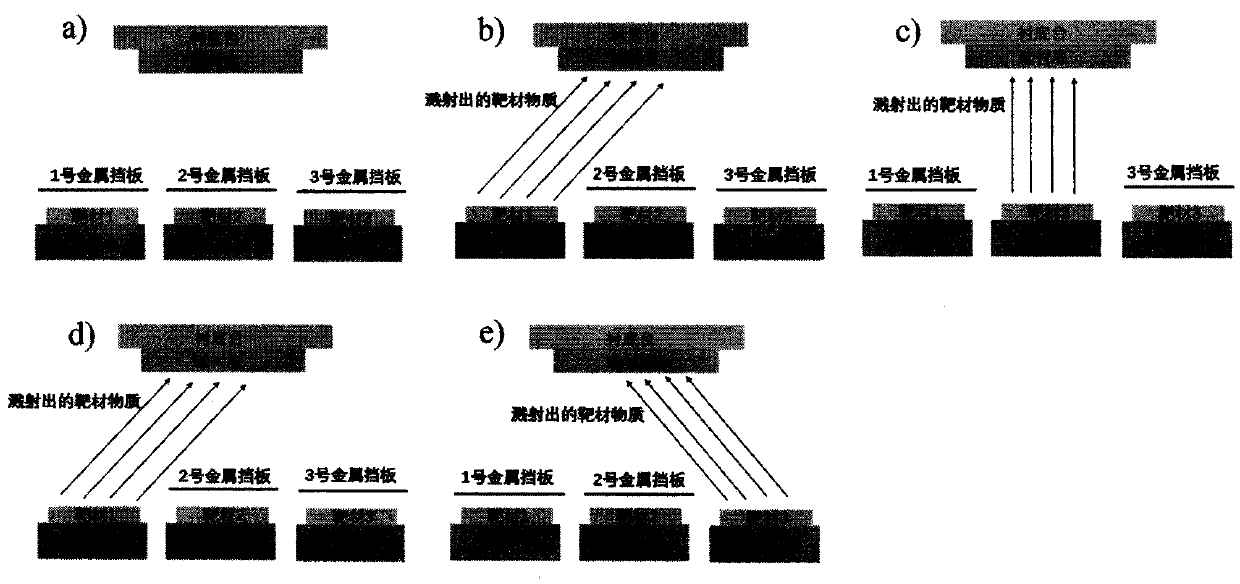

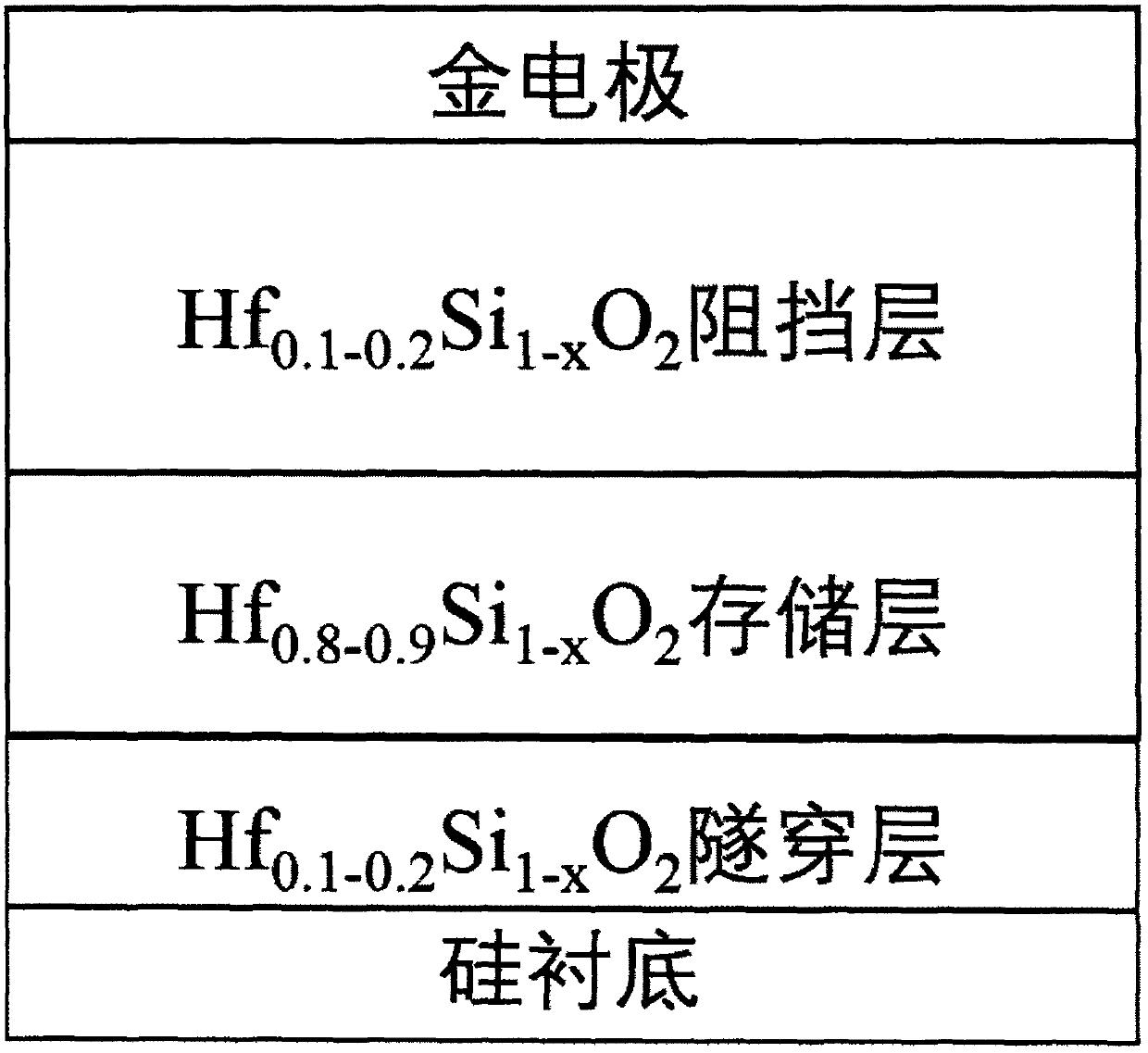

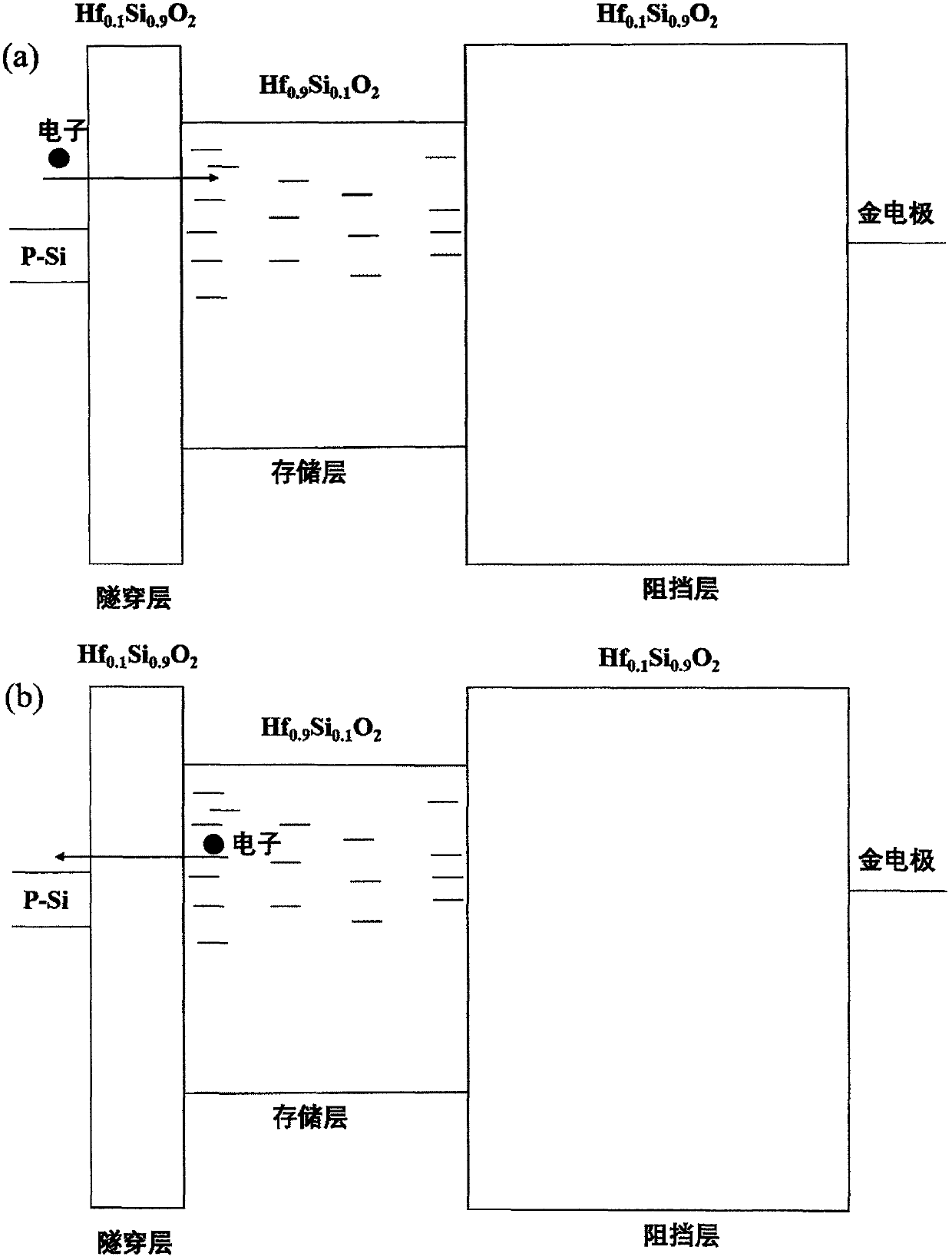

[0025] Embodiment 1: Based on p-Si substrate, prepare p-Si / Hf by means of magnetron sputtering 0.1 Si 0.9 o 2 / Hf 0.9 Si 0.1 o 2 / Hf 0.1 Si 0.9 o 2 / Au charge trap memory device fabrication process is as follows:

[0026] a) Put the silicon substrate into an appropriate amount of acetone, ultrasonically clean it, then ultrasonically clean it with deionized water, then place it in a dilute hydrogen fluoride solution to remove surface oxides, and then put it into the lining in the three-target magnetron sputtering deposition chamber On the bottom platform, prepare to grow a film on the surface; the Hf 0.1 Si 0.9 o 2 and Hf 0.9 Si 0.1 o 2 The ceramic targets were placed on the No. 1 and No. 2 target stages of the magnetron sputtering deposition chamber, and the gold target was placed on the No. 3 target stage. The temperature of the substrate stage was 300 ° C, and the vacuum in the cavity was 1 × 10 -4 Pa:

Embodiment 2

[0032] Embodiment 2: Based on p-Si substrate, prepare p-Si / Hf by means of magnetron sputtering 0.1 Si 0.9 o 2 / HfO 2 / Hf 0.1 Si 0.9 o 2 / Au charge trap memory device fabrication process is as follows:

[0033] a) Put the silicon substrate into an appropriate amount of acetone, ultrasonically clean it, then ultrasonically clean it with deionized water, then place it in a dilute hydrogen fluoride solution to remove surface oxides, and then put it into the lining in the three-target magnetron sputtering deposition chamber On the bottom platform, prepare to grow a film on the surface; the Hf 0.1 Si 0.9 o 2 and HfO 2 The ceramic targets were placed on the No. 1 and No. 2 target stages of the magnetron sputtering deposition chamber, and the gold target was placed on the No. 3 target stage. The temperature of the substrate stage was 300 ° C, and the vacuum in the cavity was 1 × 10 -4 Pa;

[0034] b) Use the metal baffle to block the ceramic targets and gold targets on the ...

Embodiment 3

[0039] Example 3: Preparation of p-Si / SiO by magnetron sputtering based on p-Si substrate 2 / Hf 0.9 Si 0.1 o 2 / SiO 2 / Au charge trap memory device fabrication process is as follows:

[0040]a) Put the silicon substrate into an appropriate amount of acetone, ultrasonically clean it, then ultrasonically clean it with deionized water, then place it in a dilute hydrogen fluoride solution to remove surface oxides, and then put it into the lining in the three-target magnetron sputtering deposition chamber On the bottom platform, prepare to grow thin films on the surface; SiO 2 and Hf 0.9 Si 0.1 o 2 The ceramic targets were placed on the No. 1 and No. 2 target stages of the magnetron sputtering deposition chamber, and the gold target was placed on the No. 3 target stage. The temperature of the substrate stage was 300 ° C, and the vacuum in the cavity was 1 × 10 -4 Pa;

[0041] b) Use the metal baffle to block the ceramic targets and gold targets on the No. 2 and No. 3 targe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com