Extrusion production line of PP co-extrusion foamed thick board

A production line and thick plate technology, applied to flat products, household appliances, other household appliances, etc., can solve the problems of production lines without PP co-extruded foamed thick plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable the examiner to further understand the structure, features and other purposes of the present invention, the attached preferred embodiments are attached with accompanying drawings in detail as follows. The embodiments illustrated in the accompanying drawings are only used to illustrate the technical solution of the present invention , not to limit the present invention. (apparatus, equipment and elements used in the present invention are routinely used in this field)

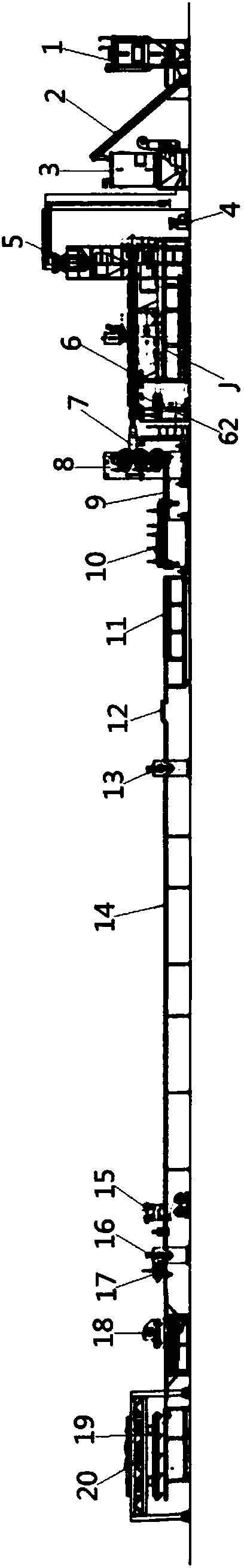

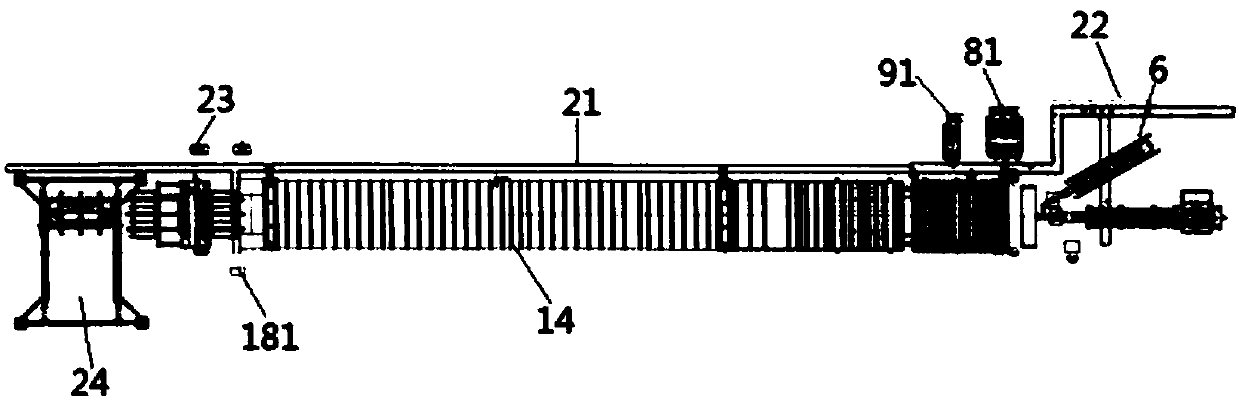

[0019] First, please refer to figure 1 , figure 1 It is a structural schematic diagram of the PP co-extruded foamed thick plate extrusion production line of the present invention. Such as figure 1 As shown, a PP co-extruded foamed thick board extrusion production line of the present invention, the PP co-extruded foamed thick board extrusion production line includes a feeding unit, a molding unit, a heat treatment unit, Cooling unit and finished product collection unit.

[0020] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com