Hydrophobic-association-type guanidine gum used for fracturing fluid and preparation method of hydrophobic-association-type guanidine gum

A hydrophobic association, fracturing fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as low viscosity and poor shear resistance, and achieve good technical effects and viscosity increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

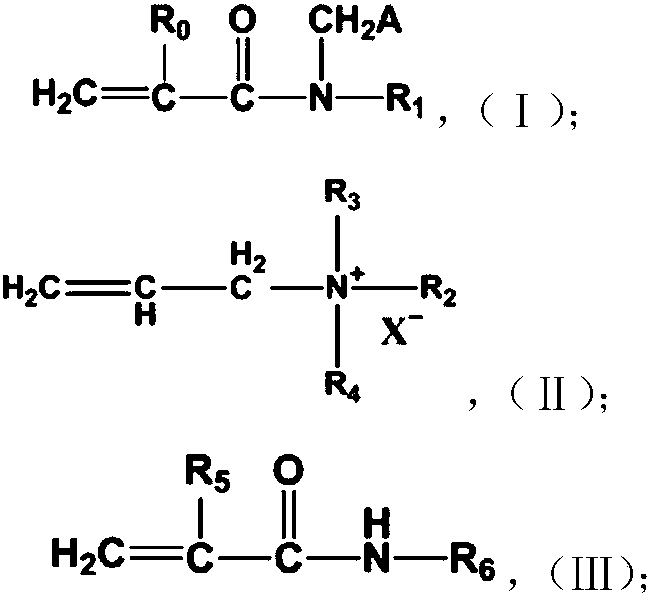

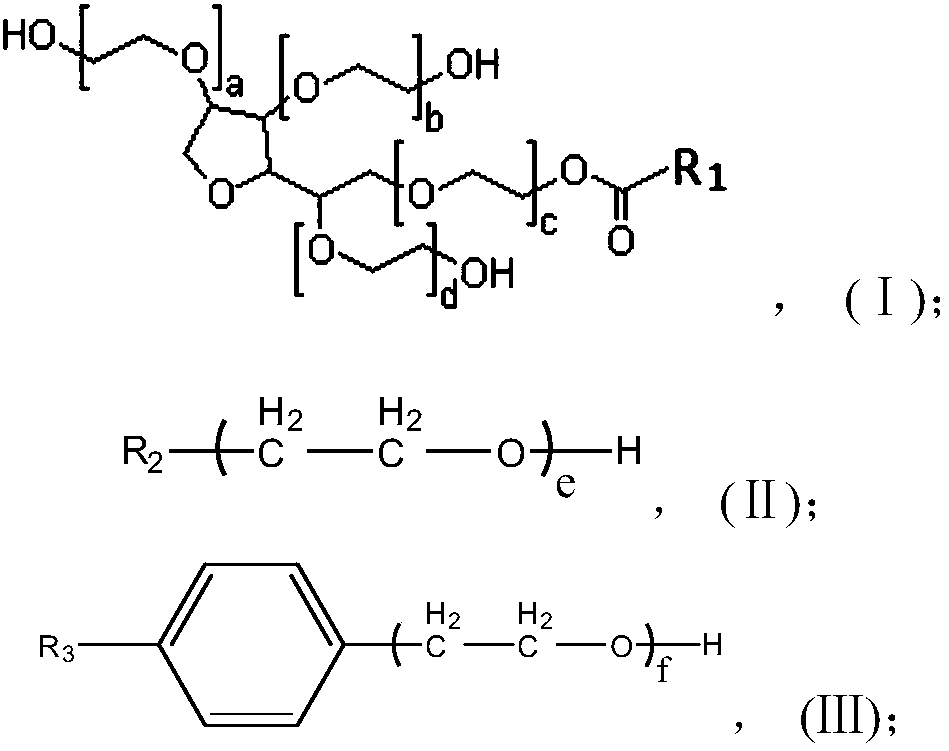

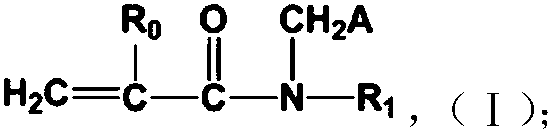

Method used

Image

Examples

Embodiment 1

[0042]Disperse 40 parts of hydroxypropyl guar gum in 100 parts of cyclohexane, stir and disperse at 500 r / min, and pass through inert gas protection. Dissolve 5 parts of acrylamide, 0.4 parts of 2-acrylamide sodium dodecylsulfonate, 0.5 parts of 2-acrylamide-2-methylpropanesulfonic acid, 2 parts of Span 80, and 0.05 parts of Tween 60 in 40 parts Prepare an aqueous solution in water and adjust the pH value to 9.0. Slowly add the aqueous monomer solution into the reaction kettle dropwise at a rate of 1 mL / min. Stirring was continued for 2 hours, and the jacket temperature of the reactor was controlled at 30°C. Prepare an aqueous solution of 0.05 parts of ceric ammonium nitrate in 10 parts of deionized water, and slowly drop it into the reaction kettle at a rate of 0.5 mL / min. At 30°C, pass inert gas protection and stir, react for 60 minutes, then raise the temperature to 60°C and continue the reaction for 60 minutes. The reaction product is taken out, centrifuged, dried, and ...

Embodiment 2

[0045] Disperse 40 parts of hydroxypropyl guar gum in 100 parts of cyclohexane, stir and disperse at 500 r / min, and pass through inert gas protection. Dissolve 5 parts of acrylamide, 0.4 part of dodecyldimethylallyl ammonium chloride, 0.5 part of 2-acrylamide-2-methylpropanesulfonic acid, 2 parts of Span 80, and 0.05 part of Tween 60 in Prepare an aqueous solution with 40 parts of water, and adjust the pH value to 9.0. Slowly add the aqueous monomer solution into the reaction kettle dropwise at a rate of 1ml / min. Stirring was continued for 2 hours, and the jacket temperature of the reactor was controlled at 30°C. Prepare an aqueous solution of 0.05 parts of ceric ammonium nitrate in 10 parts of deionized water, and slowly drop it into the reaction kettle at a rate of 0.5 ml / min. At 30°C, pass inert gas protection and stir, react for 60 minutes, then raise the temperature to 60°C and continue the reaction for 60 minutes. The reaction product is taken out, centrifuged, dried,...

Embodiment 3

[0048] Disperse 40 parts of hydroxypropyl guar gum in 100 parts of cyclohexane, stir and disperse at 500 r / min, and pass through inert gas protection. Dissolve 5 parts of acrylamide, 0.4 part of N-dodecylacrylamide, 0.5 part of 2-acrylamide-2-methylpropanesulfonic acid, 2 parts of Span 80, and 0.05 part of Tween 60 in 40 parts of water to prepare Aqueous solution, adjust the pH value to 9.0. Slowly add the aqueous monomer solution into the reaction kettle dropwise at a rate of 1ml / min. Stirring was continued for 2 hours, and the jacket temperature of the reactor was controlled at 30°C. Prepare an aqueous solution of 0.05 parts of ceric ammonium nitrate in 10 parts of deionized water, and slowly drop it into the reaction kettle at a rate of 0.5 ml / min. At 30°C, pass inert gas protection and stir, react for 60 minutes, then raise the temperature to 60°C and continue the reaction for 60 minutes. The reaction product is taken out, centrifuged, dried, and pulverized for later us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com