Four-air-flue pulverized coal burner for cement kiln

A technology of pulverized coal burner and four air ducts, which is applied in the direction of burners, burners burning powder fuel, and combustion methods, etc., which can solve complex burner adjustment operations, failure to achieve expected use effects, and short service life of cement burners. problems, to achieve the effect of superior adjustment and adaptability, strong ejection capacity, complete and powerful flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

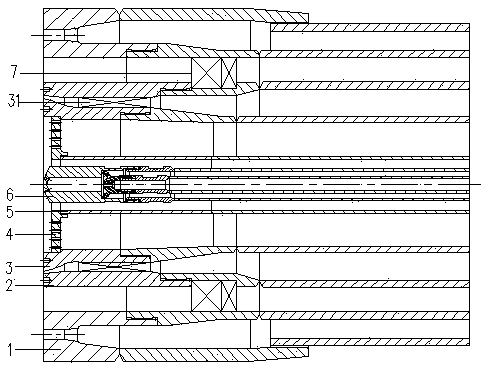

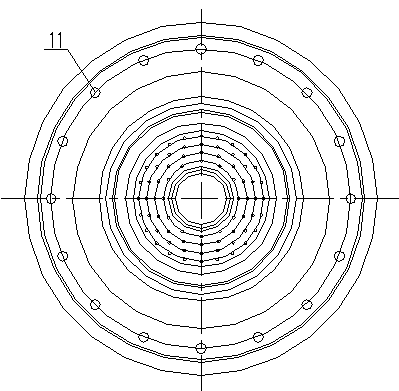

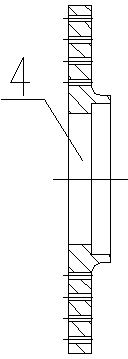

[0023] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, the nozzle of the present invention is connected with the air duct; the nozzle is composed of the swirling air inner nozzle 3 coaxially set from the inside to the outside, the pulverized coal inner nozzle 2, and the axial flow outer cylinder 1; The central air duct 5, the swirl air duct 10, the coal air duct 9, and the axial air duct 8 are composed of the outer coaxial set; the swirl air inner nozzle 3, the pulverized coal inner nozzle 2, and the axial air outer cylinder 1 The swirling air duct 10, the coal air duct 9, and the axial air duct 8 are respectively connected to the axial airtight through the connecting pipes in a threaded or welded manner. The innermost layer is provided with the central air duct 5. Four air ducts are formed: axial flow air duct, coal air duct, swirl air duct, and central air duct.

[0024] One end of the nozzle is flat, and the other end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com