High-overload resistant environmental-friendly wire

An environmentally friendly and high-resistance technology, applied in the field of electric wires, can solve problems such as poor anti-overload capability, low cost performance, and low production efficiency, and achieve good environmental protection performance, increase production efficiency, and fast production speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

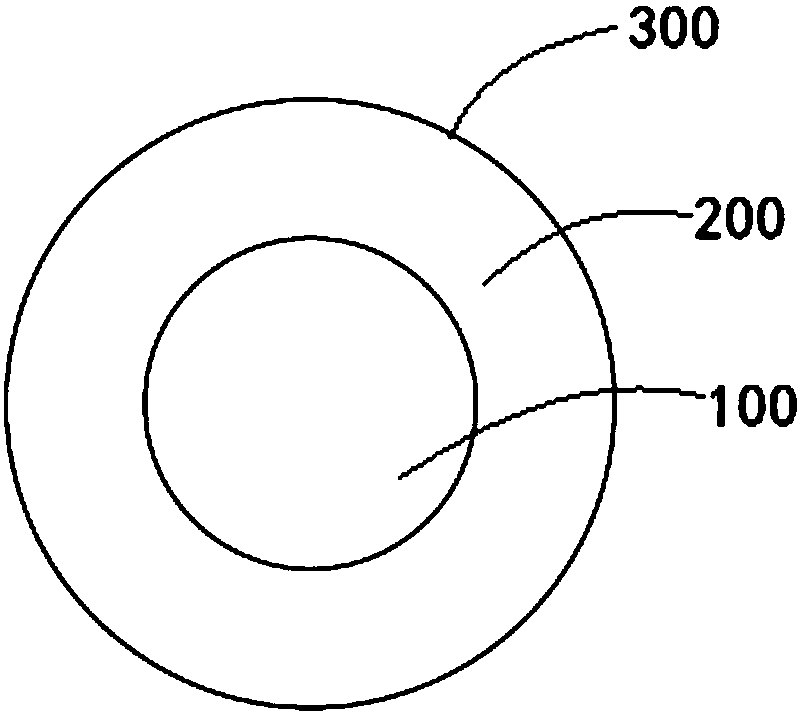

[0010] see figure 1 As shown in the figure, what is shown in the figure is a high-overload-resistant environmental protection wire, including a copper conductor 100 and an insulating layer 200 coated on the copper conductor 100 .

[0011] The insulation layer 200 includes a heat-resistant, halogen-free, low-smoke, flame-retardant polyolefin insulation layer coated on the copper conductor, a thermoplastic polyester elastomer insulation layer coated on the temperature-resistant, halogen-free, low-smoke, flame-retardant polyolefin insulation layer, and sequentially The polypropylene tape layer and the thin layer of fluoroplastic insulating layer wrapped on the thermoplastic polyester elastomer insulating layer, and the thin layer of fluoroplastic insulating layer is covered with a polyvinyl chloride coat layer 300 added with a rodent rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com