Waveguide-coupled semiconductor laser

A laser and semiconductor technology, applied in the field of lasers, can solve the problems that do not conform to the development trend of miniaturization and the large volume of lasers, and achieve the effects of simple processing, high-power laser output, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

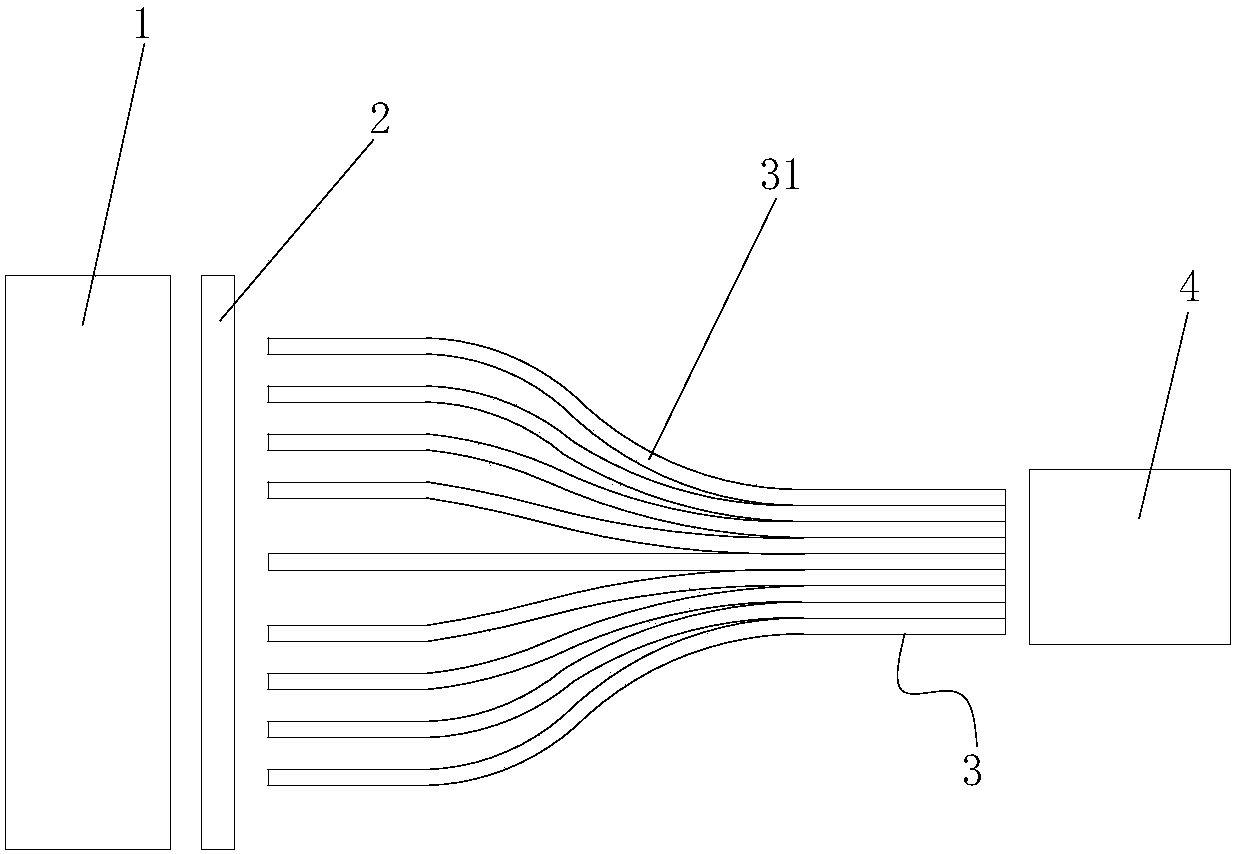

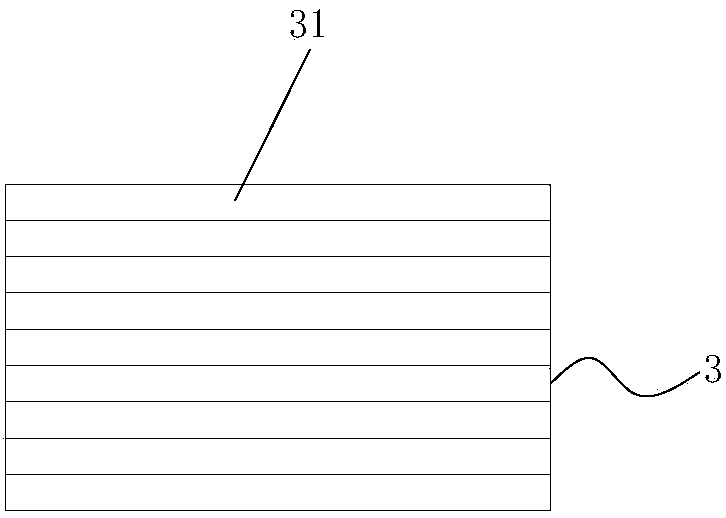

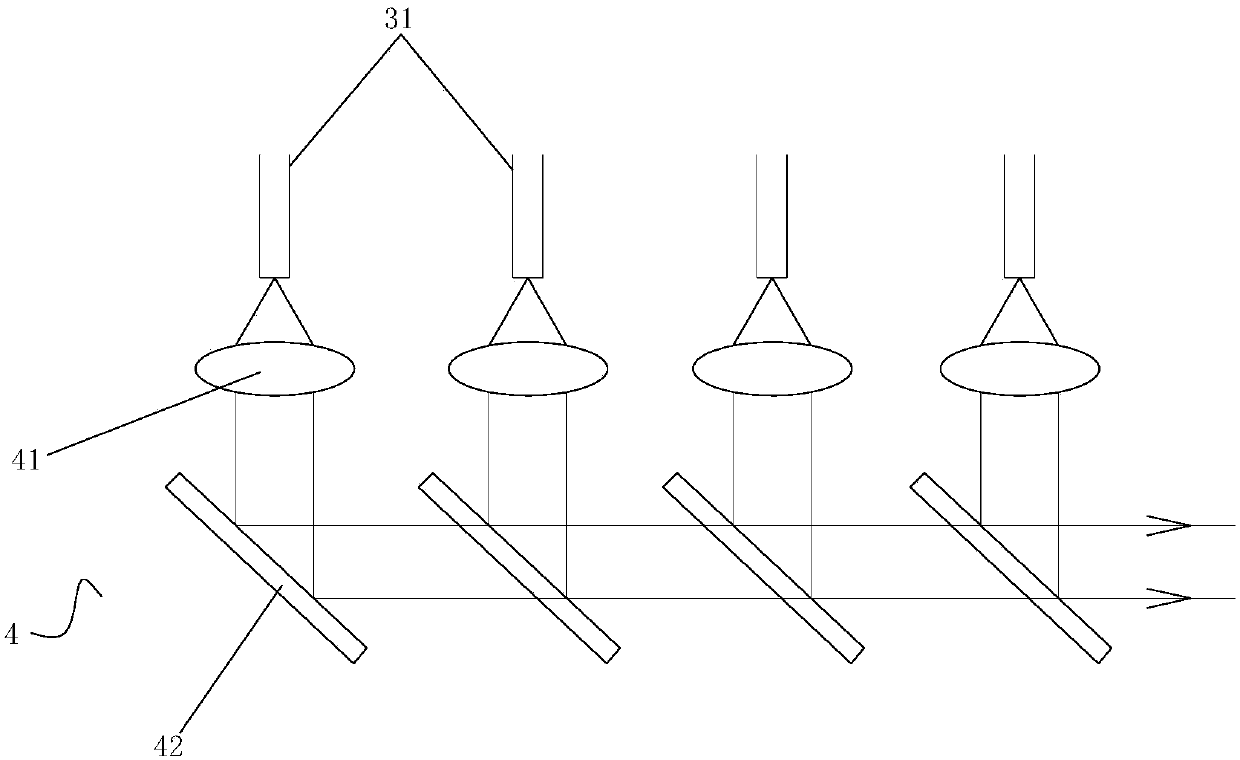

[0021] Example 1, such as figure 1 or figure 2 As shown, the light output ends of the waveguide sheets 31 are closely attached to each other sequentially, so as to realize the beam combining of the output light. In order to further improve the beam combining effect of the output light, an optical beam combining system 4 may also be provided on the side of the light output end of the waveguide coupler 3, and the optical beam combining system 4 may be a block grating. or as image 3 As shown, the optical beam combining system 4 can also be a collimator lens 41 and a WDM diaphragm 42 sequentially arranged on the light output side of each waveguide sheet 31, and the inclination angles of each WDM diaphragm 42 are the same.

[0022] In addition, as an optimization, an FBG grating can be etched on the light output end of the waveguide sheet 31 for locking the wavelength.

[0023] The working principle of this example 1: the optical input ends of each waveguide sheet 31 are coupl...

Embodiment 2

[0025] The structure and principle of embodiment 2 and embodiment 1 are basically the same, as Figure 4 or Figure 5 As shown, the difference is that the light output ends of the waveguide sheets 31 are not tightly attached together in sequence, but there are gaps between them. Due to the existence of gaps, the beam combining effect of the output light is worse than that of Embodiment 1, so an optical beam combining system 4 is arranged on the side of the light output end of the waveguide coupler 3 to improve the beam combining effect of light, thereby achieving high power output of the laser. Wherein, the photosynthetic beam system 4 may be a block grating. or as image 3 As shown, the optical beam combining system 4 can also be a collimator lens 41 and a WDM diaphragm 42 sequentially arranged on the light output side of each waveguide sheet 31, and the inclination angles of each WDM diaphragm 42 are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com