Device and method for efficiently polishing and processing high-precision balls in cluster magneto-rheological mode

A magnetorheological and high-precision technology, which is applied in the direction of surface polishing machine tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of poor processing consistency, high processing cost, and sphericity limitation, and achieve stable shape accuracy , high processing efficiency and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

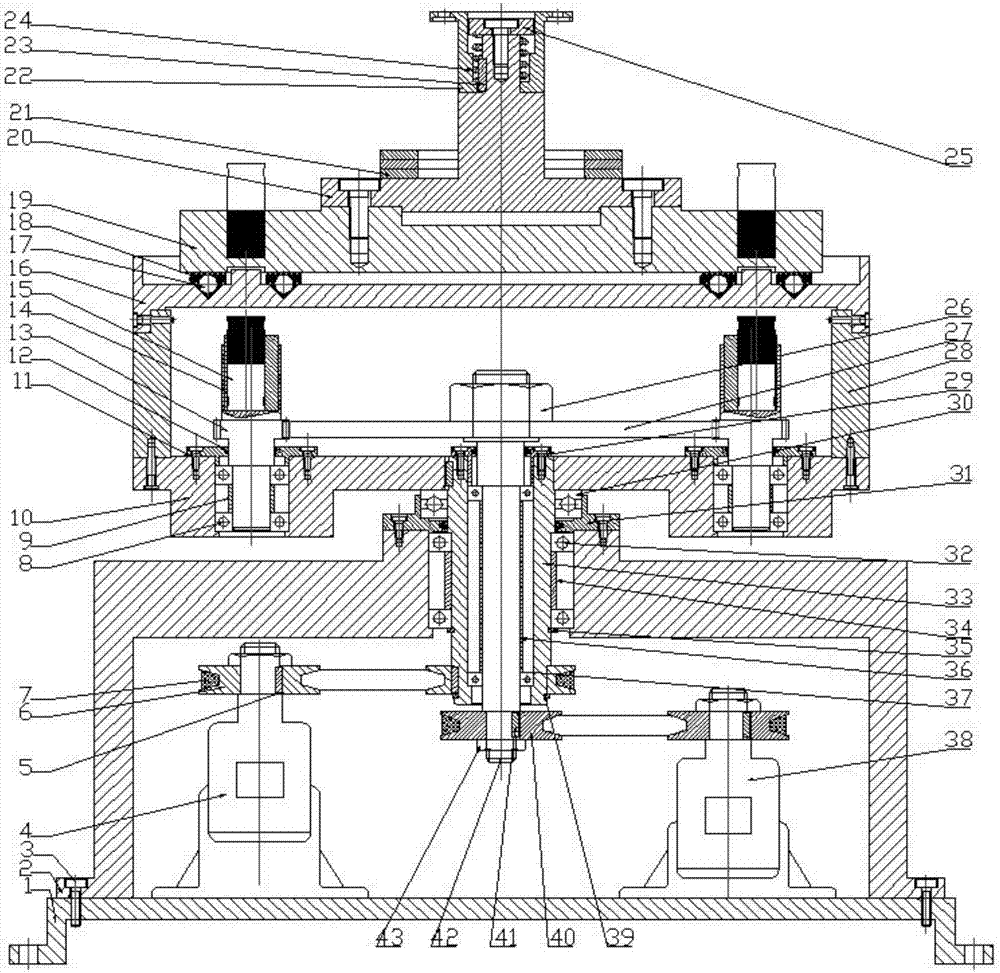

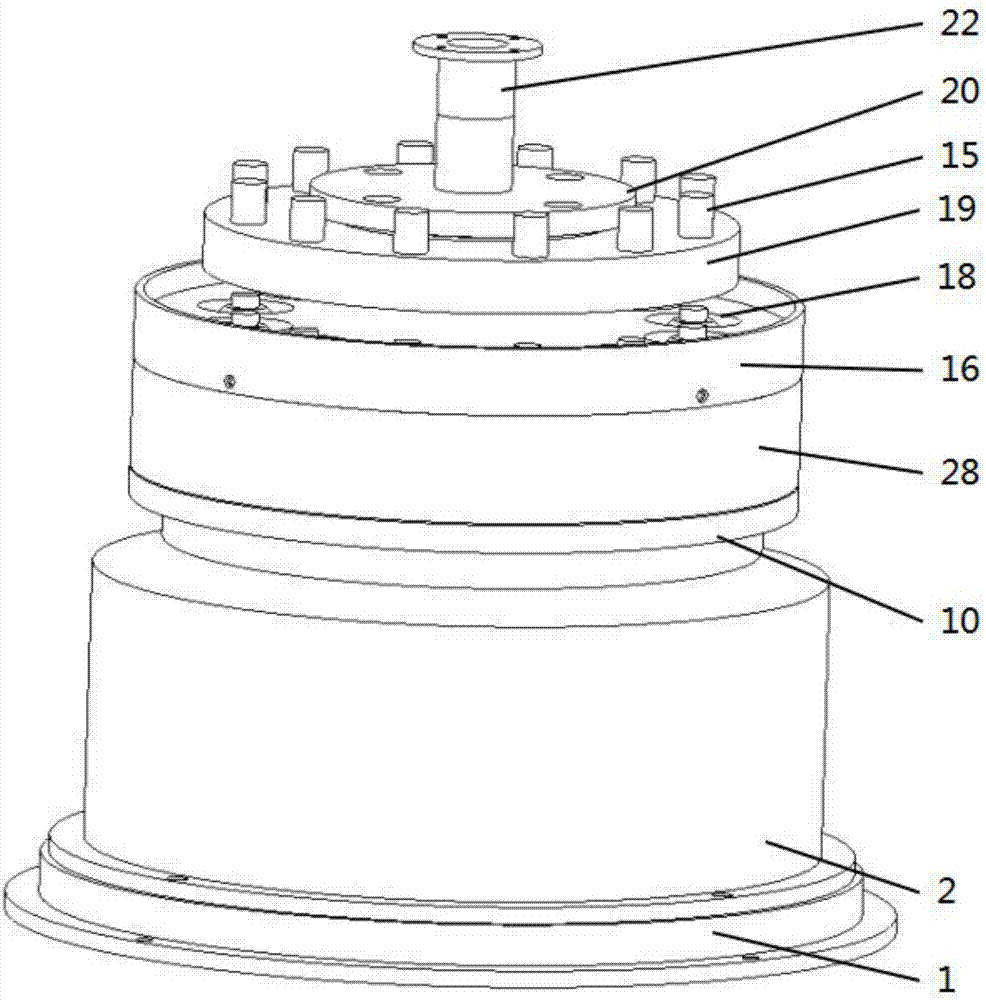

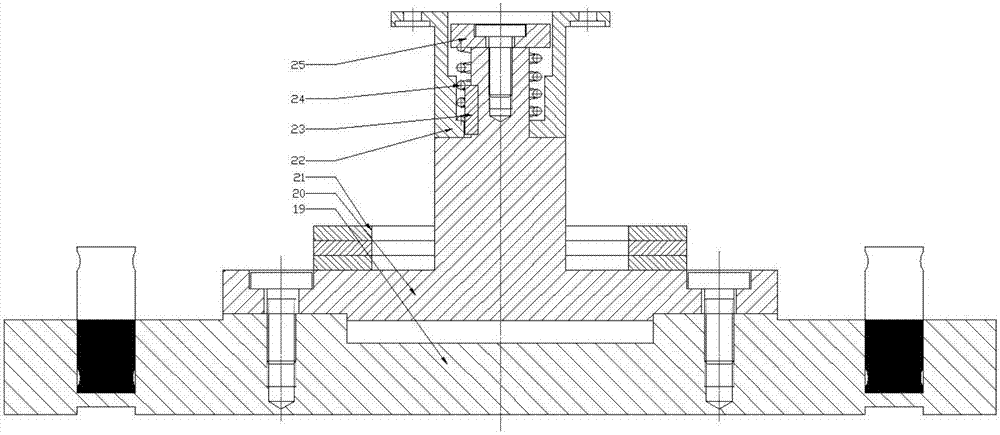

[0053] Such as Figure 1-9As shown, a kind of ceramic ball polishing processing device based on the magneto-rheological effect of the present invention includes a lower polishing disk revolution mechanism, a cluster magnetic pole eccentric rotation mechanism, an upper polishing disk and a pressure regulating mechanism, and the lower polishing disk revolution mechanism includes a bottom plate ( 1), Base (2), Thrust Ball Bearing (30), Thrust Ball Bearing Housing (31), Hollow Shaft (33), Hollow Shaft Bearing (32), Pinion Shaft Mounting Plate (10), Support Ring (28) , the lower polishing disc (16) with V-shaped groove, the hollow shaft motor (4), the timing belt (7), the hollow shaft pulley (6) parts, wherein the hollow shaft motor (4) is fixedly installed on the base plate (1) , the hollow shaft (33) and the hollow shaft bearing (32) are fixedly installed in the large center hole on the base (2), and the lower polishing disc (16) is connected to the pinion shaft mounting plate (1...

Embodiment 2

[0067] The specific structure of the device is the same as that of the specific embodiment 1.

[0068] Such as Figure 1-9 As shown, a device and method for high-efficiency cluster magnetorheological polishing and processing of high-precision balls includes the following steps:

[0069] 1) According to the characteristics of the processed ceramic balls, select a permanent magnet (15) with a suitable diameter and magnetic field strength and install it above the pinion shaft (13) in the revolution mechanism of the lower polishing disc, and adjust the angle of the eccentricity adjustment ring (14) according to requirements , so that the rotation eccentricity of each magnet is the same.

[0070] 2) Fix the revolution mechanism of the lower polishing disc and its lower parts on the mobile worktable of the CNC milling machine through nuts, and connect the upper polishing disc and the pressure regulating device to the spindle of the CNC milling machine through the upper flange.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com