Oil-electricity hybrid power vertical lifting fixed wing long-endurance unmanned aerial vehicle

An oil-electric hybrid, vertical take-off and landing technology, which is applied in the direction of vertical take-off and landing aircraft, rotorcraft, unmanned aircraft, etc. Efficiency reduction and other issues, to achieve the effect of large load capacity, excellent flight performance, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] This embodiment is a hybrid electric vertical take-off and landing fixed-wing long-endurance unmanned aerial vehicle.

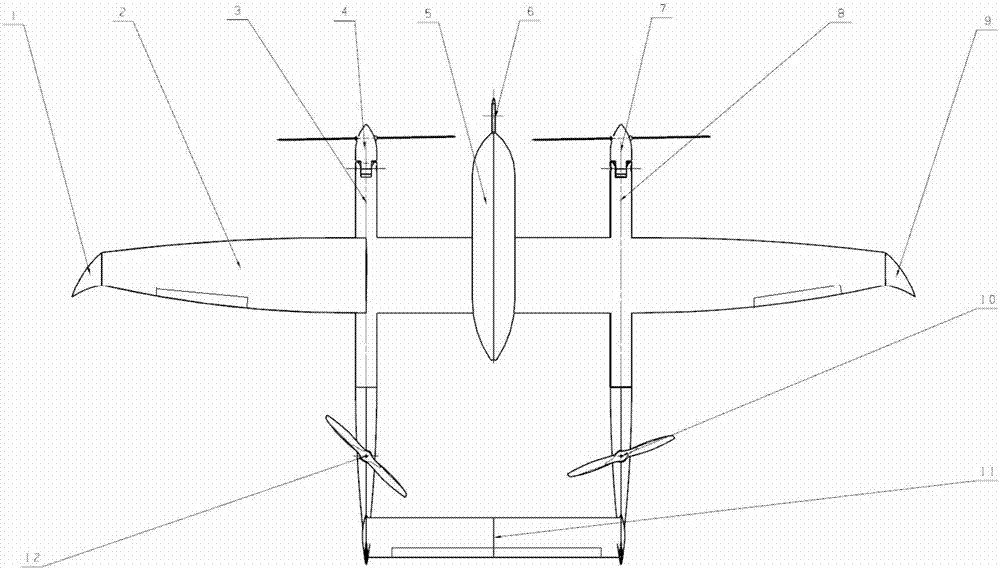

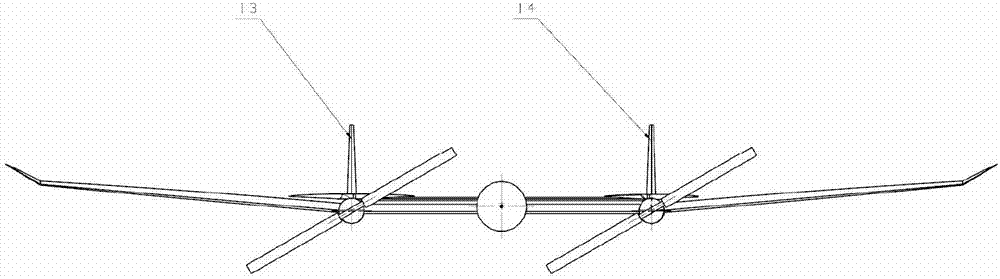

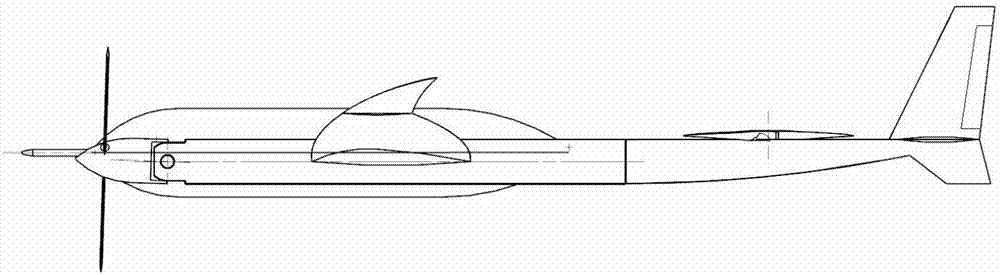

[0023] refer to Figure 1 to Figure 5 The vertical take-off and landing fixed-wing long-endurance unmanned aerial vehicle of this embodiment consists of a first winglet 1, a main wing 2, a first fuselage 3, a first fuel-powered tilting pitch system 4, Main fuselage 5, pitot tube 6, second fuel-powered tilting pitch system 7, second fuselage 8, second winglet 9, second lift motor 10, horizontal tail 11, first lift motor 12, second Vertical tail 13, the first vertical tail 14 are formed; Wherein, main fuselage 5 and first fuselage 3, second fuselage 8 are integral structures, and first fuselage 3 and second fuselage 8 are positioned at the two sides of main fuselage 5 respectively. The sides are connected by the middle wing, and the layout is symmetrical and parallel in the transverse direction. The combination of the three fuselages has more load space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com