High frequency circuit splicing experiment board

A technology of high-frequency circuits and experimental boards, which is applied in the direction of educational appliances, instruments, teaching models, etc., can solve the problems of large facing area, large number of clips, and close clip spacing, etc., to achieve reliable connection and conduction, flexible fixed size , Reduce the effect of facing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

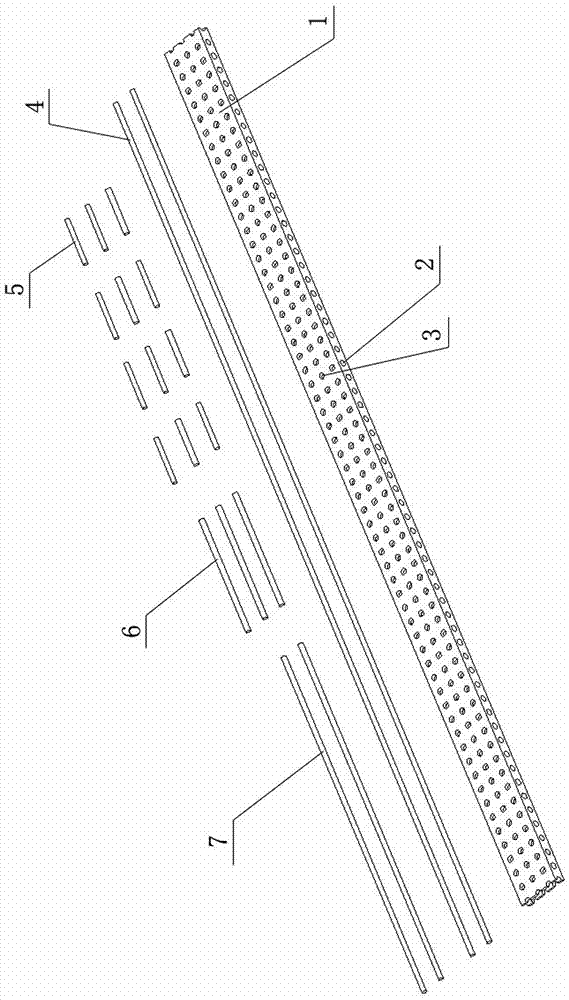

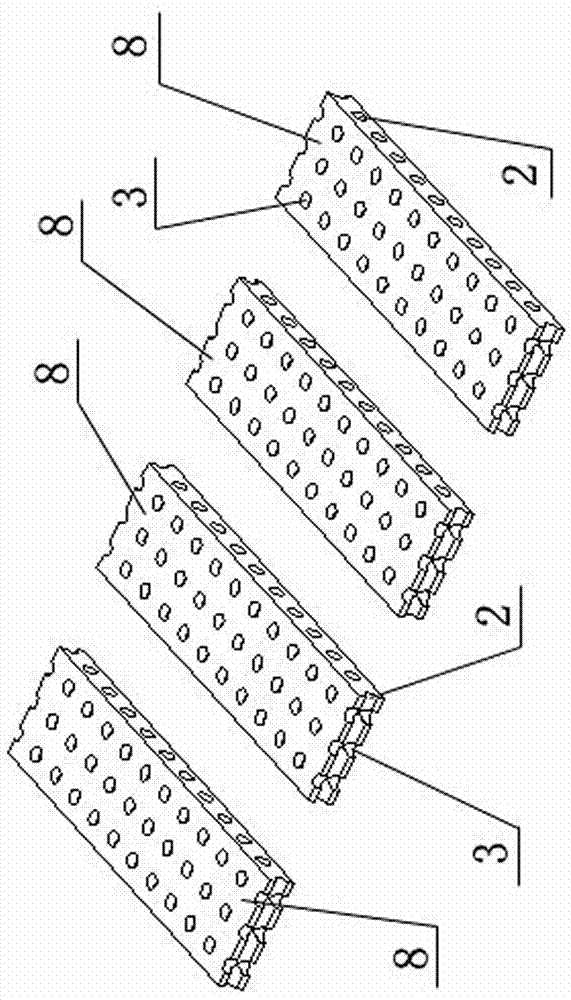

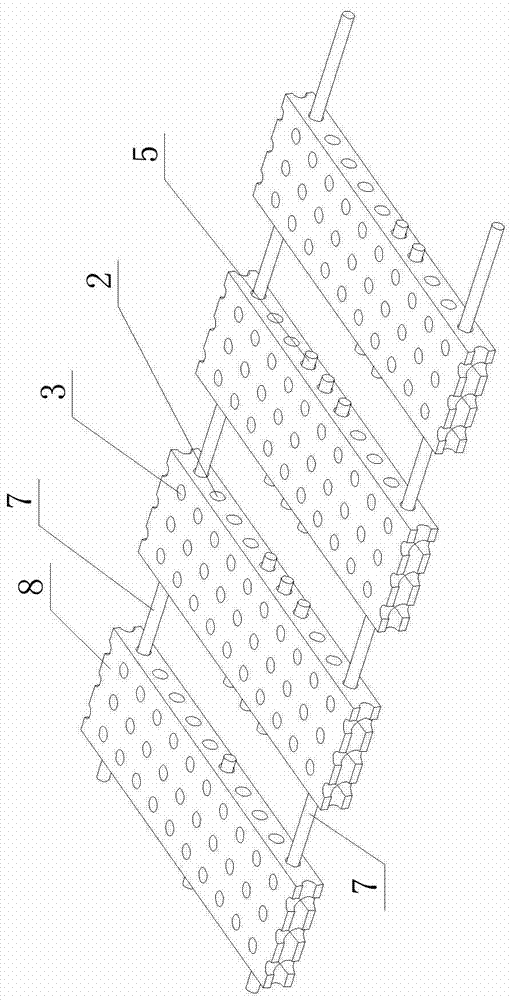

[0035] Such as figure 1 As shown, the present invention includes a rectangular resilient insulating plate with a plurality of horizontal and vertical perforations, and conductive rods that can be inserted into the horizontal perforations. There are multiple ( figure 1 Take 60 as an example) horizontal perforations that run through the original elastic insulation board, and the direction of the horizontal perforation is consistent with the width direction of the original elastic insulation board; each horizontal perforation on the original elastic insulation board is provided with a Vertical perforation, each horizontal perforation cross-connects with its corresponding vertical perforation.

[0036] The original elastic insulating board is made of insulating material with good elasticity such as silicon rubber, elastic polyvinyl chloride and the like.

[0037] Each horizontal perforation corresponds to three vertical perforations, and the three vertical perforations are evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com