Method for double-side interconnection silicon-based IGBT module employing low-temperature sintered nano-silver

A low-temperature sintering, nano-silver technology, applied in electrical components, electric solid devices, circuits, etc., can solve the problems of low connection strength, non-volatile nano-silver solder paste, low connection strength, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] The method for double-sided interconnected silicon-based IGBT modules using low-temperature sintered nano-silver specifically includes the following steps:

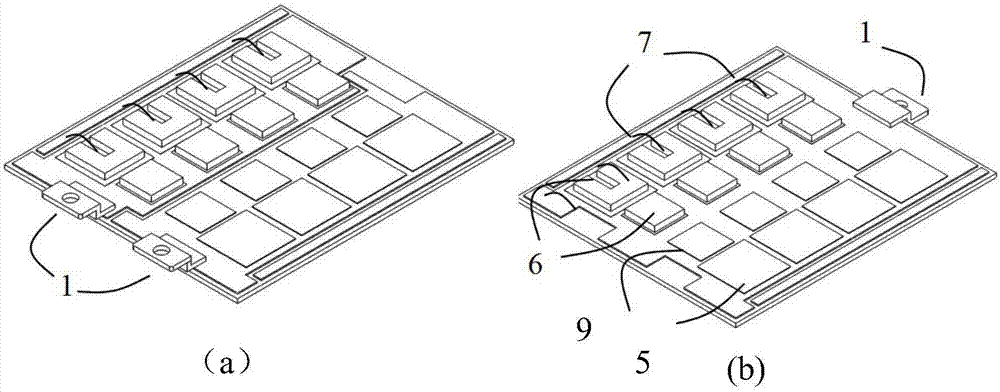

[0029] Step 1, using ultrasonic welding technology to realize the connection between the terminal 1 of the double-sided interconnected silicon-based IGBT module and the electrode area of the DBC substrate. The material of the terminal and the electrode area of the DBC substrate is pure copper. Ultrasonic welding power is 1.3-1.6W.

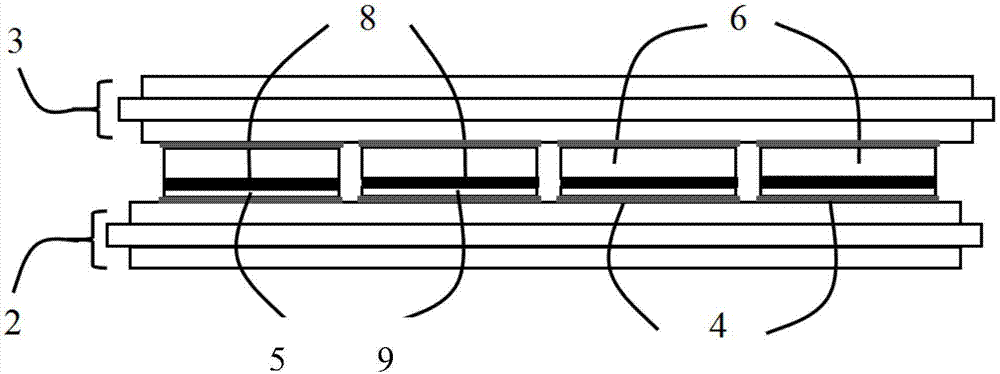

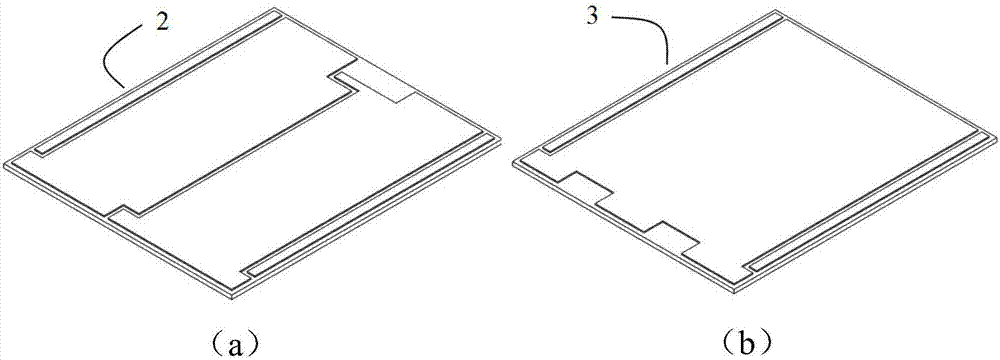

[0030] Step 2: The material of the DBC substrate is selected as a bare copper ceramic plate, which has high thermal conductivity and thermal expansion coefficient. Such as figure 2 As shown, 2 is the upper DBC substrate, and 3 is the lower DBC substrate. The impurities on the surface of the upper DBC substrate 2 and the lower DBC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com