Field repair method and quick repair adhesive for damaged composite insulator shed

A composite insulator, on-site repair technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of inconvenient on-site construction, long service life, low efficiency, etc., to achieve convenient operation, electrical performance recovery, tool light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

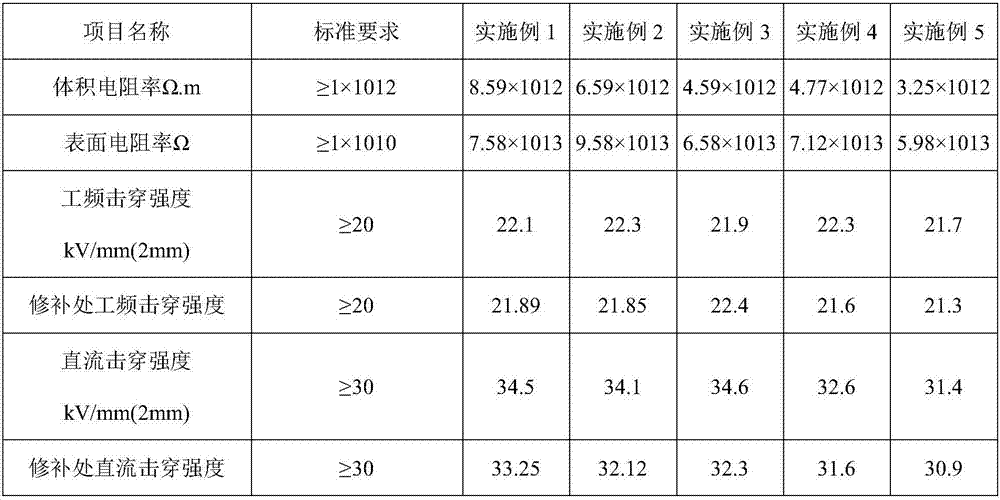

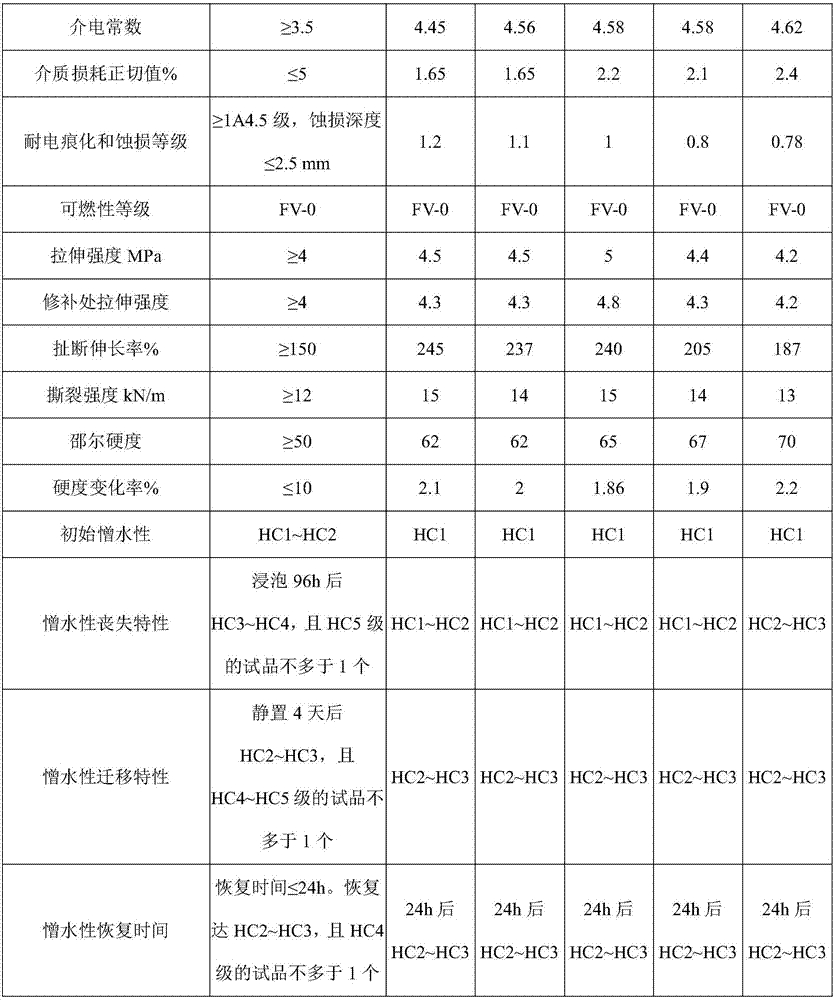

Embodiment 1

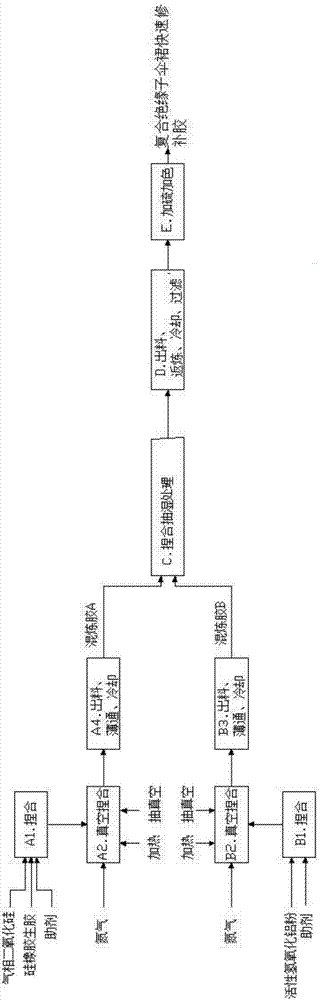

[0081] Please see attached figure 1 , the rapid repair glue of the on-site repair method for the damaged composite insulator shed of the present embodiment, which is prepared from the following raw materials in parts by weight:

[0082] 100 parts of raw silicone rubber, which is methyl vinyl silicone rubber with a vinyl content of 0.04-0.12%; 10 parts of active zinc oxide, 45 parts of modified fumed silica, and 5 parts of vinyl silicone oil , 5.1 parts of composite silane coupling agent, 0.5 parts of KH560 silane coupling agent, 12 parts of hydroxyl silicone oil, 90 parts of activated aluminum hydroxide powder, 0.2 parts of hydrogen-containing silicone oil, 0.05 parts of KH550 silane coupling agent, 0.4 parts of vulcanizing agent, color 0.5 part of mother, 0.5 part of allyl type auxiliary crosslinking agent, described allyl type auxiliary crosslinking agent is triallyl cyanurate, and described vulcanizing agent is peroxide di(2,4-di Chlorobenzoyl), the composite silane coupli...

Embodiment 2

[0123] The composite insulator quick-repair adhesive of the present embodiment comprises the following raw materials in parts by weight and is prepared as follows:

[0124] 100 parts of raw silicone rubber, which is methyl vinyl silicone rubber with a vinyl content of 0.13-0.20%; 8 parts of active zinc oxide, 40 parts of modified fumed silica, and 4 parts of vinyl silicone oil , 4.5 parts of composite silane coupling agent, 1 part of KH560 silane coupling agent, 10 parts of hydroxyl silicone oil, 105 parts of activated aluminum hydroxide powder, 1 part of hydrogen-containing silicone oil, 0.1 part of KH550 silane coupling agent, 1 part of vulcanizing agent, color 0.8 parts, 1.2 parts of allyl type auxiliary crosslinking agent, described allyl type auxiliary crosslinking agent is triallyl cyanurate, and described vulcanizing agent is p-methyl dibenzoyl peroxide , the composite silane coupling agent is a mixture of A-172 and A-151, the amount of A-172 is 4 parts, and the amount ...

Embodiment 3

[0131] The composite insulator quick-repair adhesive of the present embodiment comprises the following raw materials in parts by weight and is prepared as follows:

[0132] 100 parts of raw silicone rubber, which is methyl vinyl silicone rubber with a vinyl content of 0.21 to 0.24%; 5 parts of active zinc oxide, 35 parts of modified fumed silica, and 3 parts of vinyl silicone oil , 4 parts of composite silane coupling agent, 2 parts of KH560 silane coupling agent, 8 parts of hydroxyl silicone oil, 125 parts of activated aluminum hydroxide powder, 1.5 parts of hydrogen-containing silicone oil, 0.2 parts of KH550 silane coupling agent, 2 parts of vulcanizing agent, color 1.2 parts of mother, 2.5 parts of allyl type auxiliary crosslinking agent, described allyl type auxiliary crosslinking agent is triallyl cyanurate, and described vulcanizing agent is platinum type vulcanizing agent, and described composite silane The coupling agent is a mixture of A-172 and A-151, the amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com