Cooling water flow control device and control method for lead-acid storage battery plate casting machine

A flow control device and technology of cooling water flow, applied in the field of batteries, can solve the problems of cooling water flow difference, grid microstructure difference, affecting product quality, etc., to achieve the effect of consistency, long service life and simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

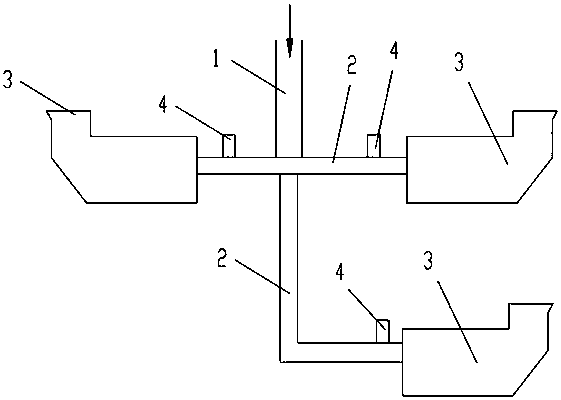

[0030] exist figure 1 In the shown embodiment, a cooling water flow control device for a lead-acid battery casting machine,

[0031] Cooling water main pipe 1, used to transport cooling water to the main water pipe of the casting machine workshop;

[0032] The cooling water pipe 2 is connected between the cooling water main pipe 1 and the casting machine 3, and is used to realize the delivery of cooling water to each casting machine 3;

[0033] A flow control device 4, the flow control device 4 is respectively arranged at the water outlet end of the cooling water pipe 2;

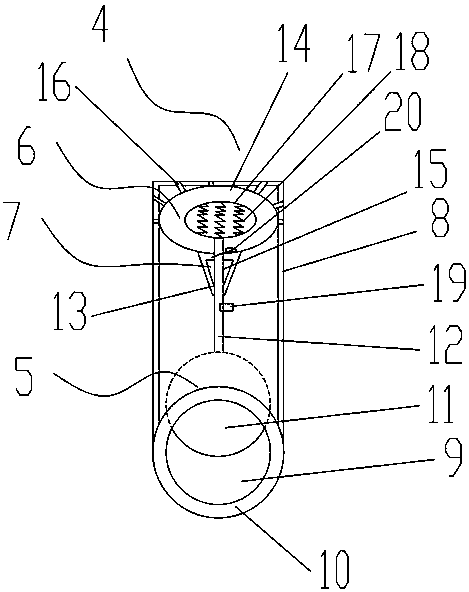

[0034] The flow control device 4 includes a flow control body 5, an automatic adjustment device 6, a lower limit flow positioning device 7 and a housing 8; the flow control body 5 is provided with an automatic control switch 19, and the automatic control device 6 is provided with an automatic control switch 19 signal connected displacement sensor 20;

[0035] The flow control body 5 is provided with a flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com