Machining technology of battery pack magnesium alloy tray for new energy vehicle

A new energy vehicle and processing technology, which is applied in the field of processing technology of magnesium alloy trays for battery packs used in new energy vehicles, can solve problems such as unstable quality, restricting the development of magnesium material preparation, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Processing technology of magnesium alloy tray for battery packs used in new energy vehicles, including:

[0047] Sand filling step: After setting the size of magnesium alloy profiles and pipes, the material is cut, and then poured with magnesia. The mesh number of magnesia is 60-100 mesh. After filling, oscillate. The filling speed is 3L / min, and the oscillation frequency is 8 times. / Second;

[0048] Bending steps: Put the magnesium alloy profiles and pipes into the heating furnace to heat, the heating temperature is 320°C, carry out pinch displacement detection, and then perform primary bending and secondary bending on the magnesium alloy profiles and tubes, primary bending and secondary bending The bending moment torque is 2000Nm, and then the size inspection and correction are carried out;

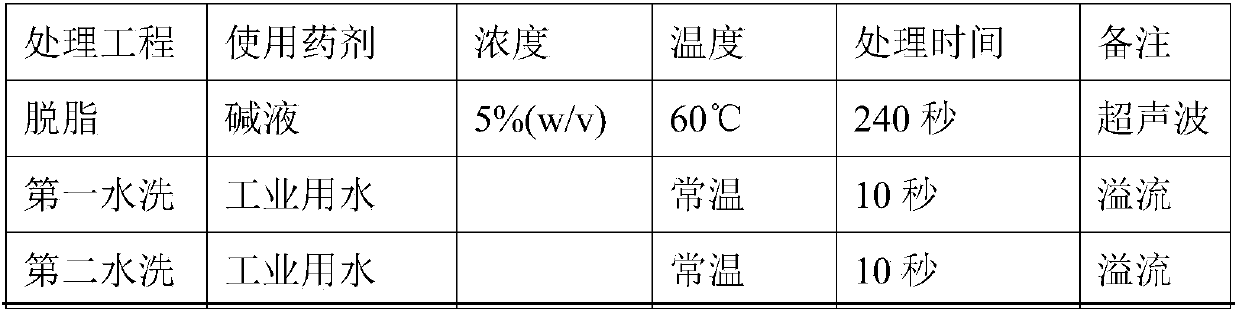

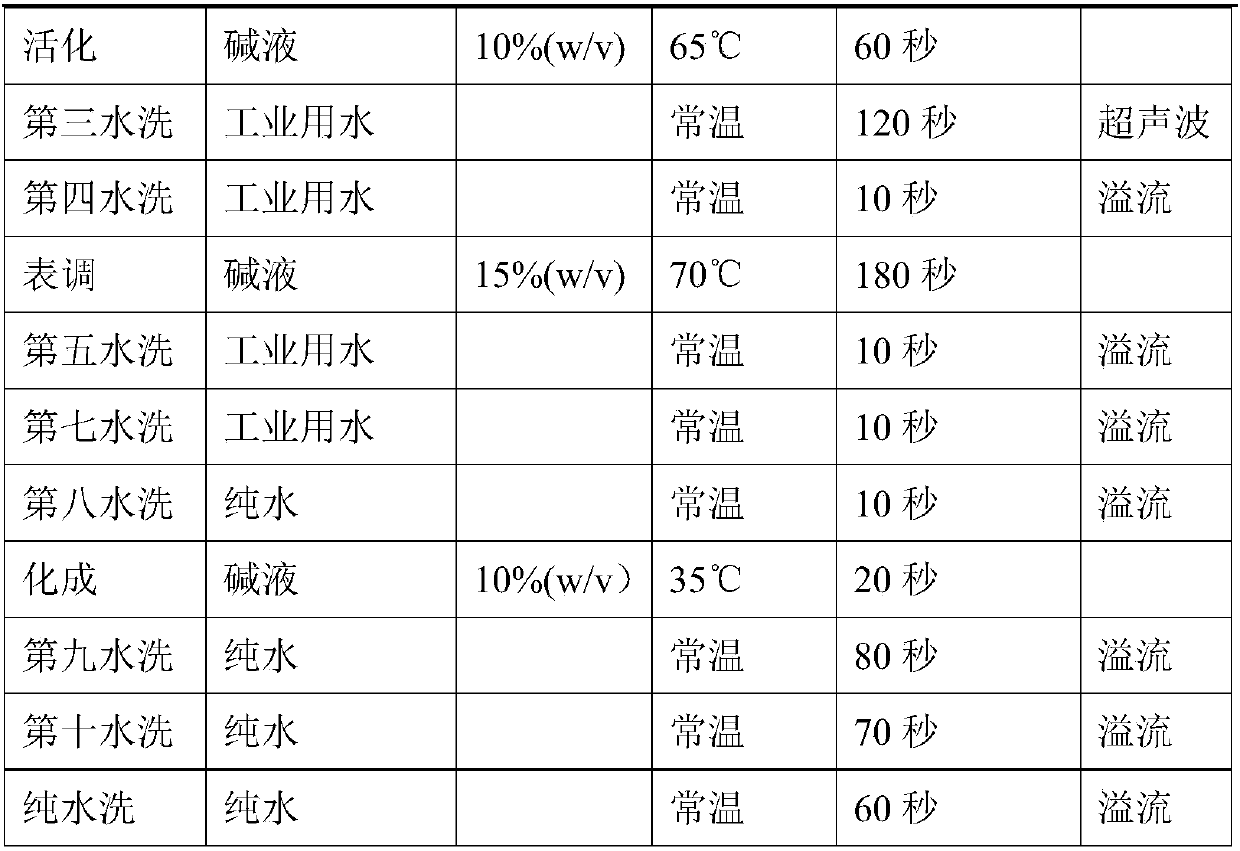

[0049] Welding steps: process the welded end section of magnesium alloy profiles and pipes on a milling machine, after feeding and feeding, clamp and position the welding stati...

Embodiment 2

[0056] Processing technology of magnesium alloy tray for battery packs used in new energy vehicles, including:

[0057] Sand filling step: after setting the size of the magnesium alloy profile and pipe, the material is cut, and then the magnesia is poured. The mesh number of the magnesia is 60 mesh. After filling, it oscillates. The filling speed is 4L / min, and the oscillation frequency is 6 times / second. ;

[0058] Bending steps: Put the magnesium alloy profiles and pipes into the heating furnace to heat, the heating temperature is 300°C, carry out pinch displacement detection, and then perform primary bending and secondary bending on the magnesium alloy profiles and pipes, primary bending and secondary bending The bending moment and torque of bending are all 1800Nm, and then the dimensional inspection and correction are carried out;

[0059] Welding steps: process the welding end section of magnesium alloy profiles and pipes on a milling machine, after feeding and feeding, ...

Embodiment 3

[0067] Processing technology of magnesium alloy tray for battery packs used in new energy vehicles, including:

[0068] Sand filling step: after setting the size of the profile and pipe, the material is cut, and then the magnesia is poured. The mesh number of the magnesia is 100 mesh. After filling, it oscillates. The filling speed is 4.5L / min, and the oscillation frequency is 10 times / s. Obtain magnesium alloy profiles and pipes;

[0069] Bending steps: Put the magnesium alloy profiles and pipes into the heating furnace to heat, the heating temperature is 350°C, carry out pinch displacement detection, and then perform primary bending and secondary bending on the magnesium alloy profiles and tubes, primary bending and secondary bending The bending moment torque of bending is 3000Nm, and then the dimensional inspection and correction are carried out;

[0070] Welding steps: process the welding end section of magnesium alloy profiles and pipes on a milling machine. After feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com