Dual-fermentation milk beverage and making method thereof

A double-fermentation and inoculation-fermentation technology, which is applied to bacteria and lactobacilli used in dairy products and food preparation, can solve problems such as raw material processing and complex production processes, lack of double-fermented milk-flavored beverages, and pH reduction of fermented fruit and vegetable juices. , to achieve the effect of preventing cardiovascular disease, improving hyperlipidemia and lowering cholesterol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] 1. Proportion

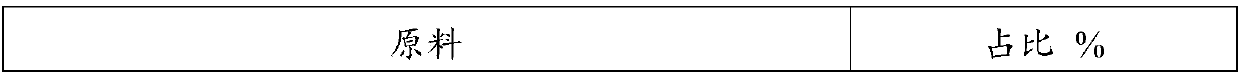

[0064] Table 1-1 Ratio of fermented milk A base material

[0065]

[0066]

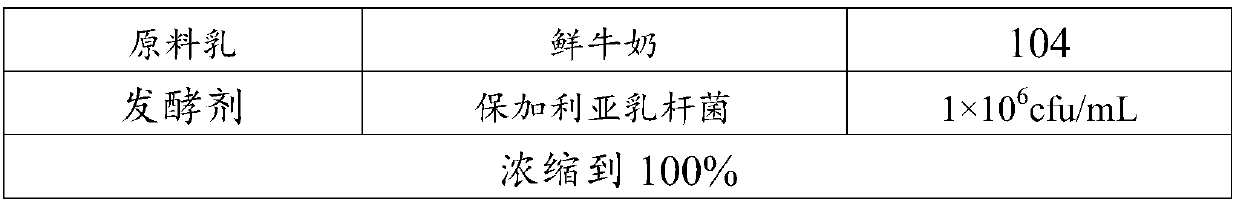

[0067] Table 1-2 Proportion of Fermented Fruit and Vegetable Juice B

[0068]

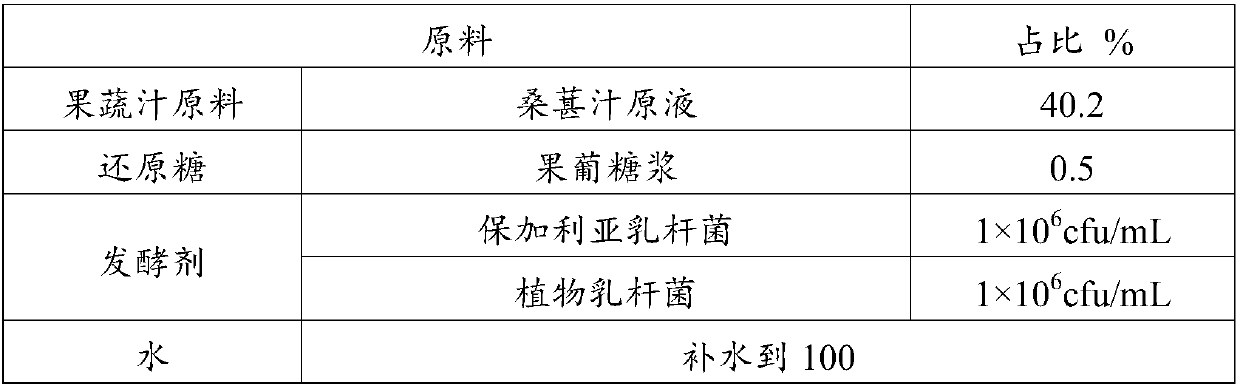

[0069] Table 1-3 Ratio of double fermentation base material

[0070]

[0071] 2. Method

[0072] (1) According to the ratio in Table 1-1, concentrate the raw milk, pass through 15Mpa, 54°C primary homogenization, sterilize at 90°C for 5 minutes, cool the concentrated milk to 37°C, add starter according to the ratio in Table 1-1 , carry out fermentation, stop fermentation when the acidity reaches 100 ° T; secondary cooling to 2 ° C, to obtain fermentation base A.

[0073] (2) Stir and mix the fruit and vegetable juice raw materials, reducing sugar and water at 20°C for 30 minutes according to the ratio in Table 1-2, filter, sterilize at 90°C for 5 minutes, cool the mixture to 25°C, and mix according to the composition in Table 1-2 than adding a starter, fermenting at 25°C, stopping the...

Embodiment 2

[0078] 1. Proportion

[0079] Table 2-1 Ratio of fermented milk A base material

[0080]

[0081] Table 2-2 Proportion of Fermented Fruit and Vegetable Juice B

[0082]

[0083] Table 2-3 Ratio of double fermentation base material

[0084]

[0085]

[0086] 2. Method

[0087] (1) According to the ratio in Table 2-1, concentrate the raw milk, after 55°C, 16Mpa primary homogenization, sterilize at 91°C for 5 minutes, cool the concentrated milk to 38°C, add according to the ratio in Table 2-1 The starter is fermented, and the fermentation is stopped when the acidity reaches 70°T; the fermentation base material A is obtained by secondary cooling to 5°C.

[0088] (2) Stir and mix the fruit and vegetable juice raw materials, reducing sugar and water according to the ratio in Table 2-2 at 30°C for 28 minutes, filter, sterilize at 91°C for 5 minutes, cool the mixture to 26°C, and mix according to the composition in Table 2-2 than adding a starter, fermenting at 26°C, s...

Embodiment 3

[0093] 1. Proportion

[0094] Table 3-1 Ratio of fermented milk A base material

[0095]

[0096] Table 3-2 Proportion of Fermented Fruit and Vegetable Juice B

[0097]

[0098]

[0099] Table 3-3 Ratio of double fermentation base material

[0100]

[0101] 2. Method

[0102](1) Concentrate the raw milk according to the ratio in Table 3-1. Under the condition of 56°C, 16Mpa first-level homogenization, 2Mpa second-level homogenization, 92°C sterilization for 6 minutes, and the concentrated milk is cooled to 40°C, according to Table 3 The ratio of -1 is added with a starter, and the fermentation is carried out, and the fermentation is stopped when the acidity reaches 90°T; the fermentation base material A is obtained by secondary cooling to 6°C.

[0103] (2) Stir and mix the fruit and vegetable juice raw materials, reducing sugar and water at 40°C for 25 minutes according to the ratio in Table 3-2, filter, sterilize at 92°C for 6 minutes, cool the mixture to 27°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com