Camelia oil and preparation method thereof

A technology of camellia oil and camellia oil, which is applied in the direction of fat oil/fat refining, fat oil/fat production, fat production, etc., can solve the problems of high energy consumption, poor product quality and high production cost, and achieve high oxidation stability and production cost. Low, skin-protecting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

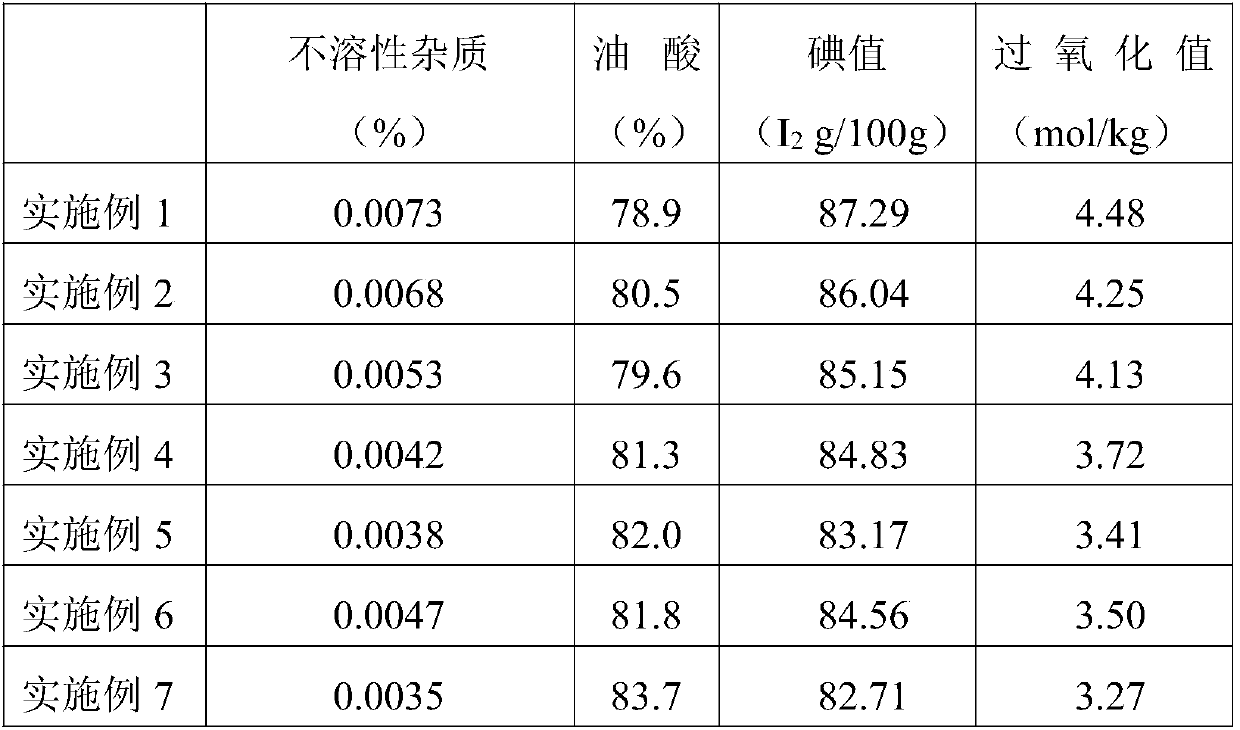

Examples

Embodiment 1

[0056] The preparation method of camellia oil comprises the following steps:

[0057] (1) Select mature Camellia oleifera seeds, remove dust by dust removal fan and remove iron impurities by permanent magnetic roller, dry the cleaned Camellia oleifera seeds at 60°C with a flat dryer until the moisture content is 5%, and peel them off by a sheller Remove the shell, grind, and pass through a 30-mesh sieve to obtain Camellia oleifera seed powder;

[0058] (2) Add distilled water 5 times the weight of the camellia oleifera seed powder to the camellia oleifera seed powder, homogenize 3 times under the condition of a homogenizing pressure of 20 MPa, each time for 2 minutes, to obtain a mixed solution;

[0059] (3) Adjust the pH of the mixture to 5.0, heat to 90°C for 30 minutes, then cool to 60°C, add 2% amylase by weight of camellia oleifera seed powder, mix well, and react for 5 minutes at a speed of 180 rpm. hour, the reaction solution was cooled to room temperature, centrifuged...

Embodiment 2

[0065] The preparation method of camellia oil comprises the following steps:

[0066] (1) Select mature Camellia oleifera seeds, remove dust by dust removal fan and remove iron impurities by permanent magnetic roller, dry the cleaned Camellia oleifera seeds at 60°C with a flat dryer until the moisture content is 5%, and peel them off by a sheller Remove the shell, grind, and pass through a 30-mesh sieve to obtain Camellia oleifera seed powder;

[0067] (2) Add distilled water 5 times the weight of the camellia oleifera seed powder to the camellia oleifera seed powder, homogenize 3 times under the condition of a homogenizing pressure of 20 MPa, each time for 2 minutes, to obtain a mixed solution;

[0068] (3) Adjust the pH of the mixture to 5.0, heat to 90°C for 30 minutes, then cool to 60°C, add 2% amylase by weight of camellia oleifera seed powder, mix well, and react for 5 minutes at a speed of 180 rpm. hour, the reaction solution was cooled to room temperature, centrifuged...

Embodiment 3

[0074] The preparation method of camellia oil comprises the following steps:

[0075] (1) Select mature Camellia oleifera seeds, remove dust by dust removal fan and remove iron impurities by permanent magnetic roller, dry the cleaned Camellia oleifera seeds at 60°C with a flat dryer until the moisture content is 5%, and peel them off by a sheller Remove the shell, grind, and pass through a 30-mesh sieve to obtain Camellia oleifera seed powder;

[0076] (2) Add distilled water 5 times the weight of the camellia oleifera seed powder to the camellia oleifera seed powder, homogenize 3 times under the condition of a homogenizing pressure of 20 MPa, each time for 2 minutes, to obtain a mixed solution;

[0077] (3) Adjust the pH of the mixture to 5.0, heat to 90°C for 30 minutes, then cool to 60°C, add 2% amylase by weight of camellia oleifera seed powder, mix well, and react for 5 minutes at a speed of 180 rpm. hour, the reaction solution was cooled to room temperature, centrifuged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com