Electroplating process and electroplating equipment thereof

A technology of electroplating process and electroplating equipment, applied in the field of electroplating process and electroplating equipment, to achieve the effects of reasonable design, enhanced potential, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

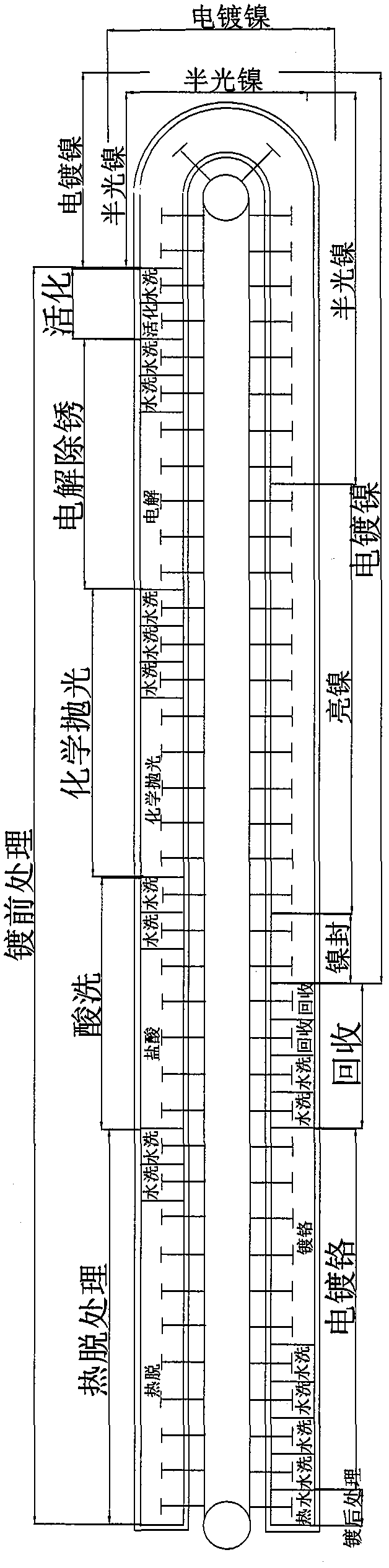

[0035] Such as figure 1 , 3 , a kind of electroplating process shown in 4 and electroplating equipment thereof, wherein, described electroplating process mainly comprises the following steps:

[0036] Step 1: Pre-plating treatment, which mainly performs dust removal, rust removal and other treatments on the surface of the electroplated workpiece. The pre-plating treatment includes the following processes in sequence:

[0037] a. Heat removal treatment: place the electroplated workpiece in water at a temperature of 40°C to degrease the surface of the electroplated workpiece for 245 seconds, then clean the electroplated workpiece with water for 50 seconds;

[0038] b. pickling: put the electroplated workpiece after process a into 40% concentration of hydrochloric acid for cleaning, the processing time is 175 seconds, then clean the electroplated workpiece after pickling with water, the cleaning time is 50 seconds;

[0039]c. Chemical polishing: place the electroplated workpiec...

Embodiment example 2

[0051] Such as figure 1 , 3 , a kind of electroplating process shown in 4 and electroplating equipment thereof, wherein, described electroplating process mainly comprises the following steps:

[0052] Step 1: Pre-plating treatment, which mainly performs dust removal, rust removal and other treatments on the surface of the electroplated workpiece. The pre-plating treatment includes the following processes in sequence:

[0053] a. Heat removal treatment: place the electroplated workpiece in water at a temperature of 100°C to degrease the surface of the electroplated workpiece for 175 seconds, then clean the electroplated workpiece with water for 70 seconds;

[0054] b. pickling: put the electroplated workpiece after process a into 60% concentration of hydrochloric acid for cleaning, the processing time is 125 seconds, then clean the electroplated workpiece after pickling with water, the cleaning time is 70 seconds;

[0055] c. Chemical polishing: place the electroplated workpi...

Embodiment example 3

[0067] Such as figure 1 , 3 , a kind of electroplating process shown in 4 and electroplating equipment thereof, wherein, described electroplating process mainly comprises the following steps:

[0068] Step 1: Pre-plating treatment, which mainly performs dust removal, rust removal and other treatments on the surface of the electroplated workpiece. The pre-plating treatment includes the following processes in sequence:

[0069] a. Heat removal treatment: place the electroplated workpiece for 210 seconds, and then clean the electroplated workpiece with water for 60 seconds;

[0070]b. pickling: put the electroplated workpiece after process a into 50% hydrochloric acid for cleaning, the treatment time is 150 seconds, then clean the electroplated workpiece after pickling with water, the cleaning time is 60 seconds;

[0071] c. Chemical polishing: Place the electroplated workpiece after the b process into the polishing mixture mixed with 30g / L ammonium bifluoride, 15g / L oxalic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com