Construction method for quick hole forming and concrete pouring of anti-slide pile auger drill

A construction method and a technology of rotary drilling, which are applied to drilling equipment and methods, buildings, drilling equipment, etc., can solve the problems of non-recyclability, poor environmental protection benefits, and high construction costs of concrete lock ring beams, and reduce operational safety. hidden dangers, improve work efficiency, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

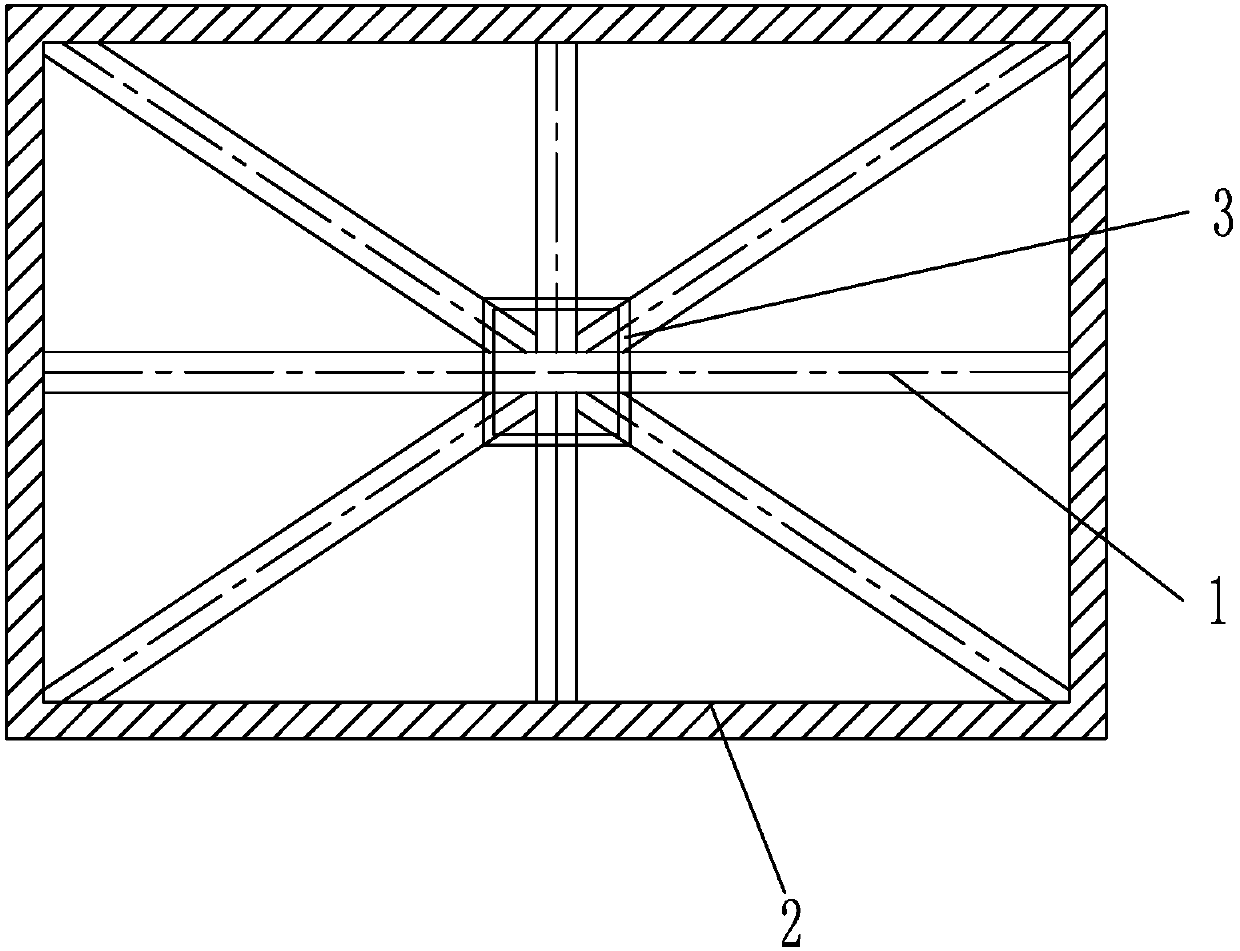

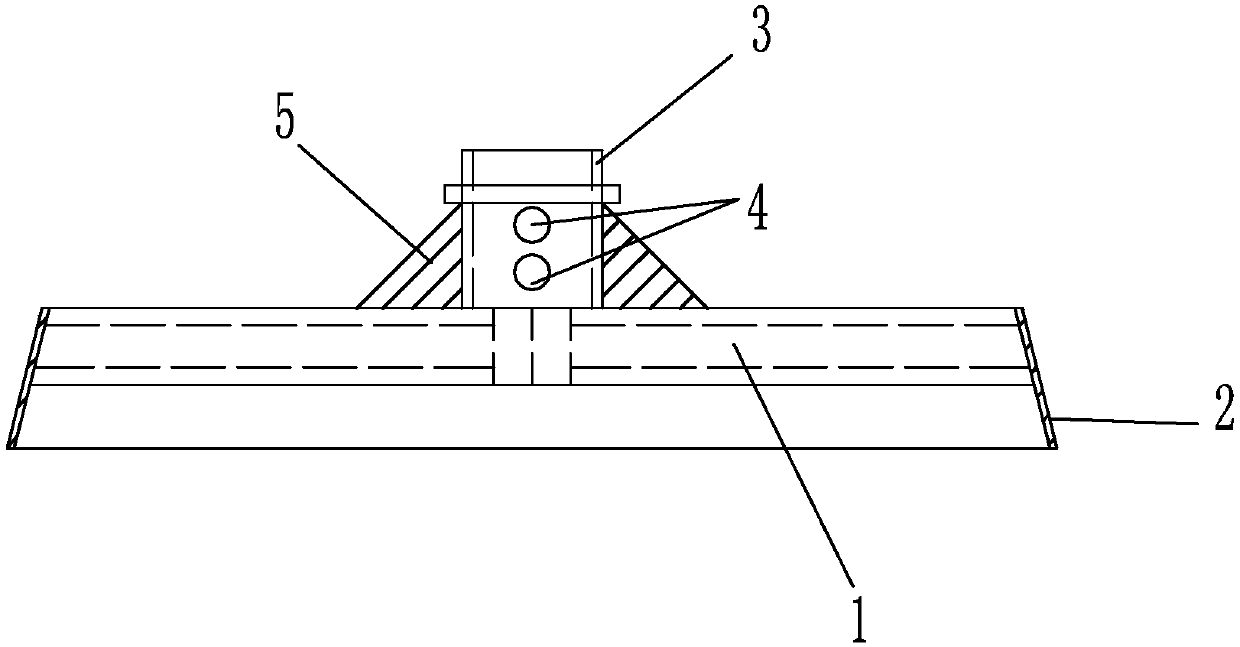

[0023] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0024] A construction method for rapid hole formation and concrete pouring of anti-sliding pile rotary drilling drills, which is carried out according to the following construction steps:

[0025] The first step is to measure and set out to determine the position and elevation of the pile hole.

[0026] The second step is to level and compact the site at the orifice.

[0027] In the third step, the orifice steel casing is installed and fixed. The cross-section of the steel casing is rectangular (periphery is slightly larger than the size of the pile body by 2-3cm), and the pile top (body) is 100-130cm in the range of 100-130cm according to the stakeout position and size of the pile hole (the excavation depth is the length of the steel casing). About 3 / 5) of the soil body will be manually excavated, and the steel casing will be hoisted into the excavatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com