Optical acoustic excitation and detection integrated probe based on side edge polishing and grinding fiber grating and manufacturing method and test method of optical acoustic excitation and detection integrated probe

A technology for fiber gratings and manufacturing methods, applied in measuring devices, using optical devices to transmit sensing components, converting sensor outputs, etc., can solve problems such as large size and complex structure, and achieve large signal bandwidth, small volume, and simple production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this description, the principle of the present invention will be described through implementation. Other aspects, features and advantages of the present invention will become clear through the detailed description.

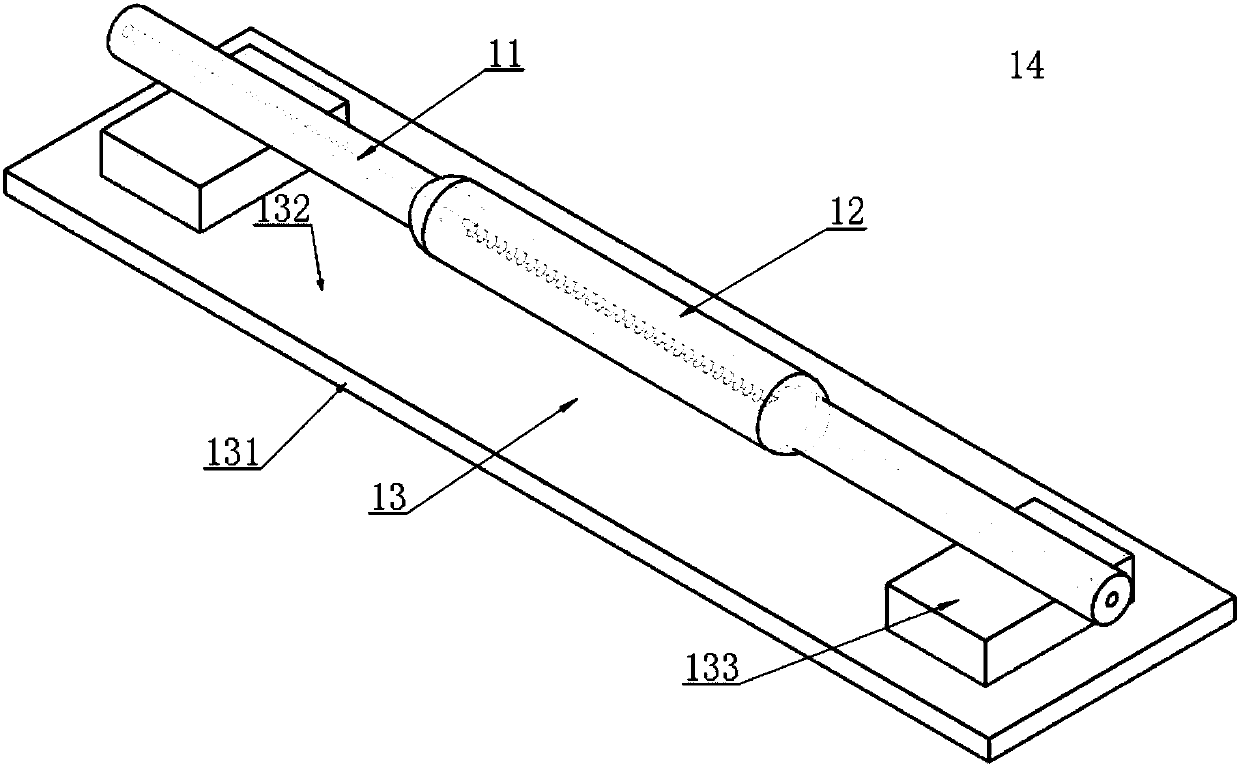

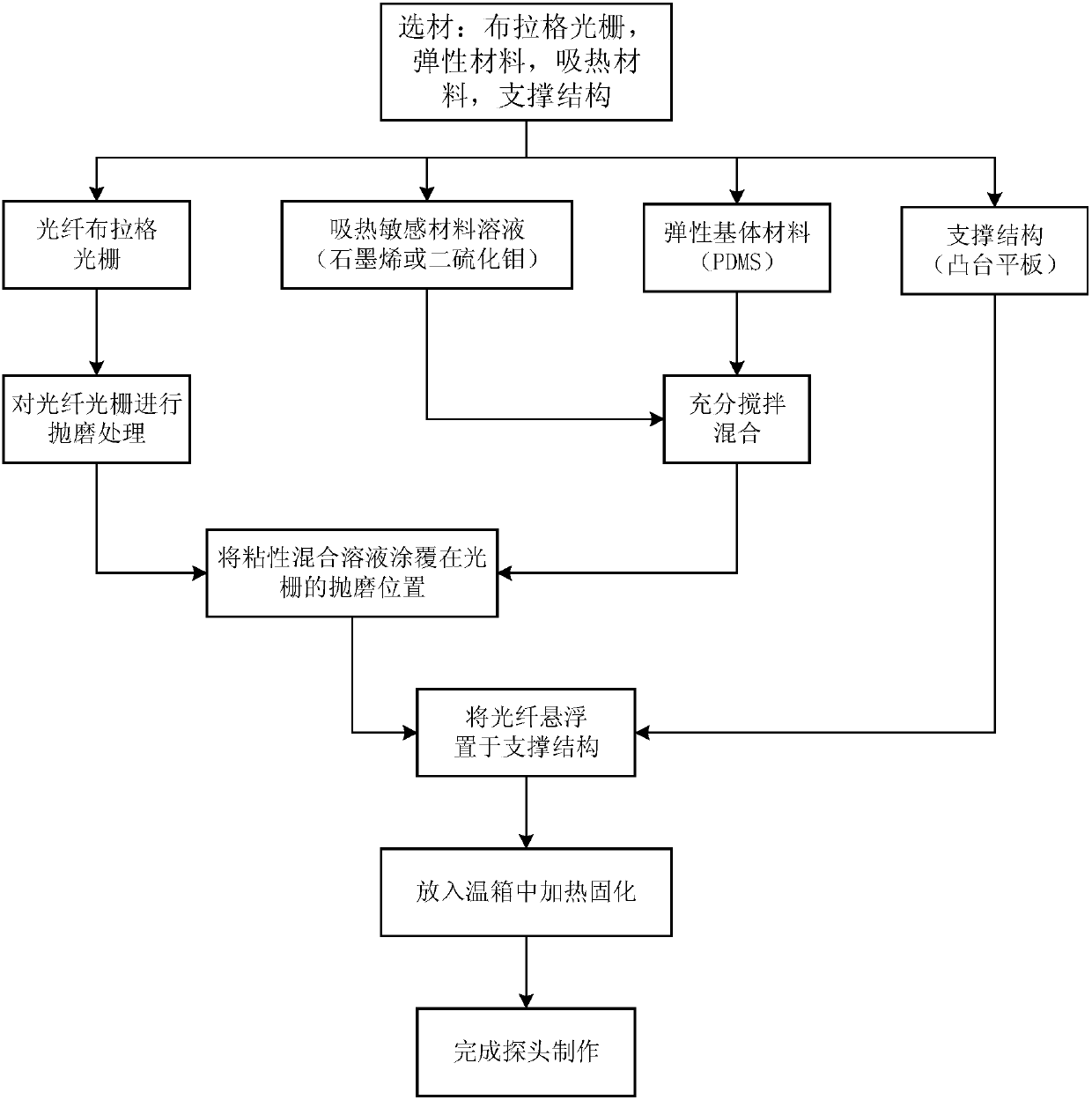

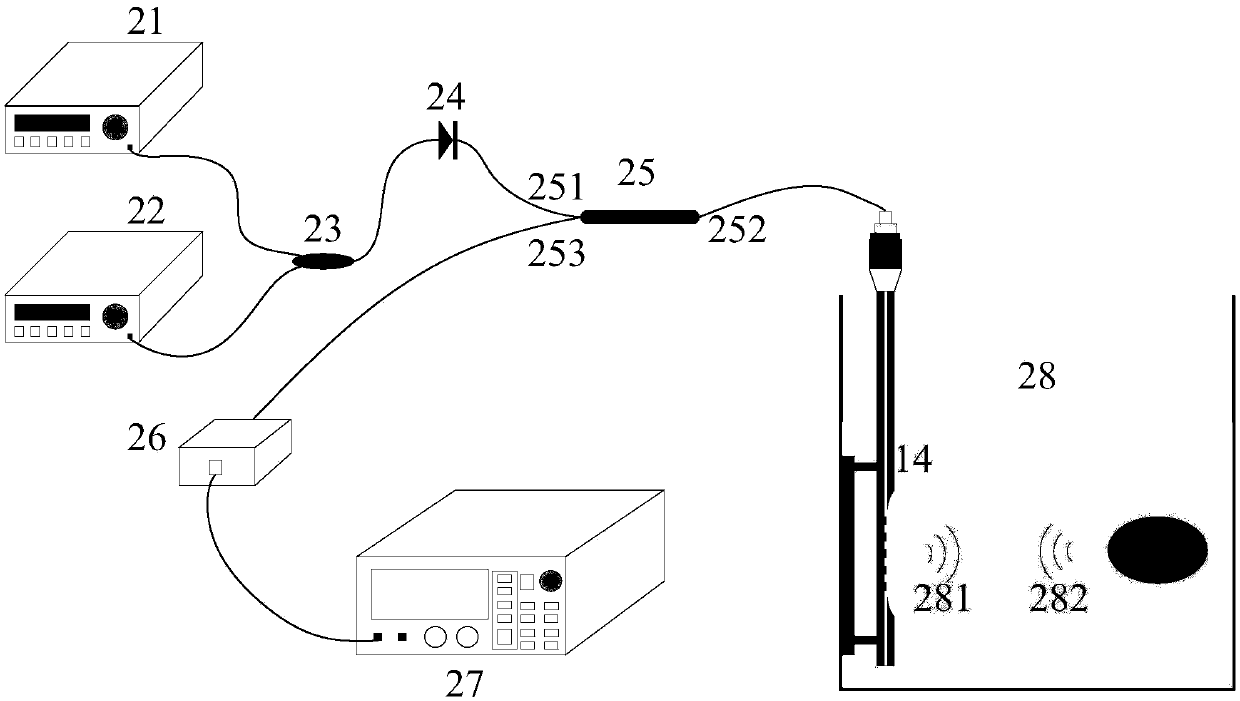

[0031] figure 1 It is a structural schematic diagram of the photoacoustic excitation and detection integrated probe based on the side-polished fiber grating of the present invention. The integrated probe 14 is mainly composed of a side-polished fiber grating 11 , a functional component 12 mixed with an elastic matrix material and an endothermic sensitive material, and a support structure 13 . The side-polished fiber grating 11 is a single-mode fiber, and its fiber grating structure is made by ultraviolet light exposure, and is made by side-polishing the grating area by means of wheel-type mechanical polishing; The functional component 12 desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com