Photoconductive material for laser printing and method for preparing photosensitive drum

A photoconductive material and laser printing technology, applied to the equipment of the electrical recording process using the charge pattern, the electrical recording process using the charge pattern, optics, etc., can solve the problems of light printing color, insufficient properties of the photoconductive material, hollow characters, etc. , to achieve the effect of improving fatigue resistance and wear resistance, improving light guide performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

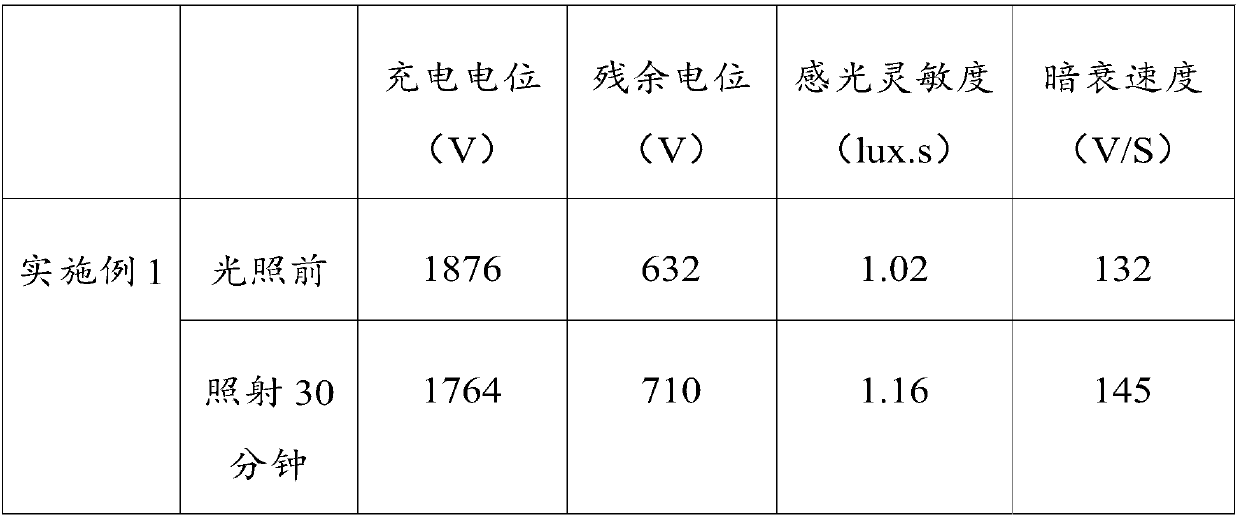

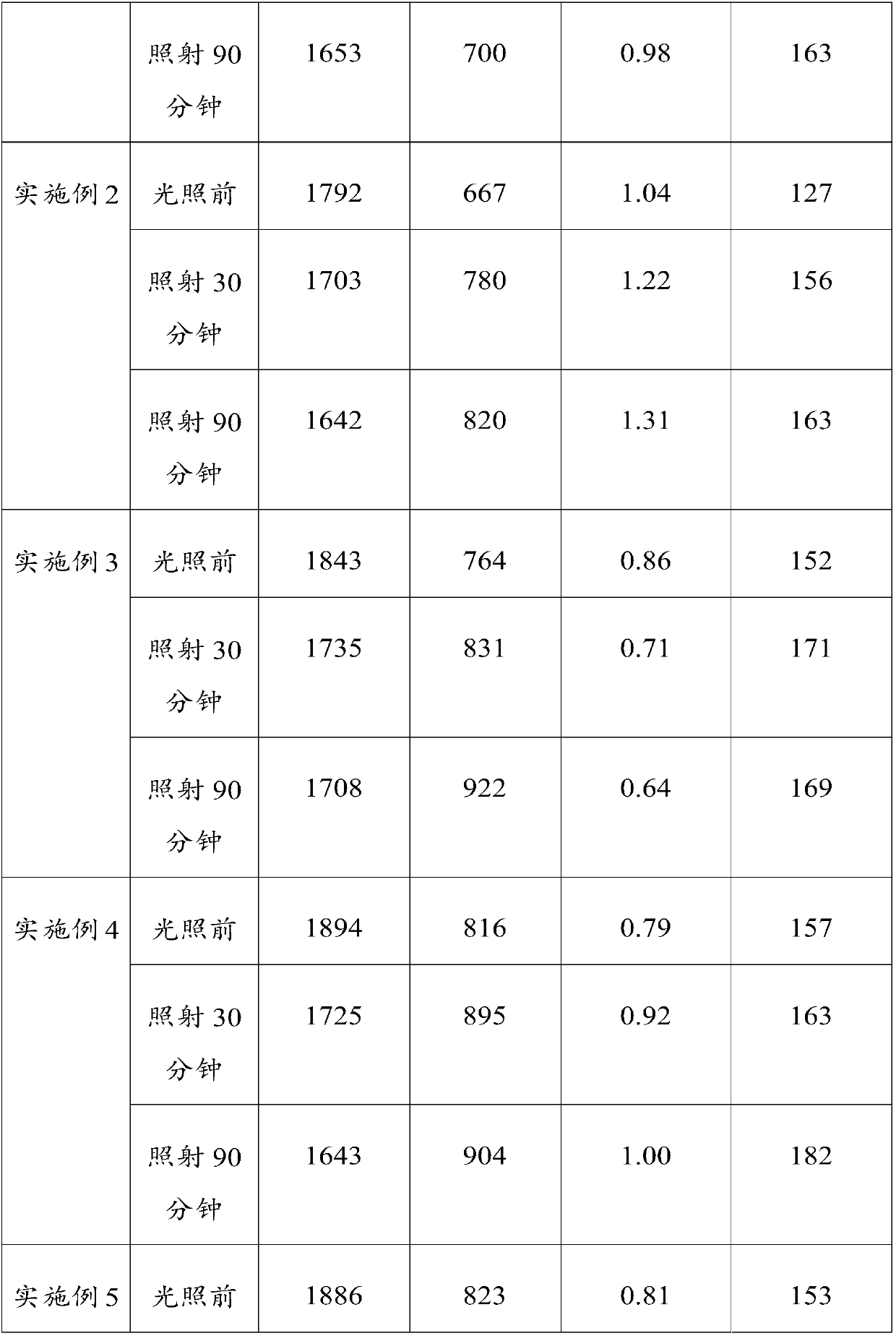

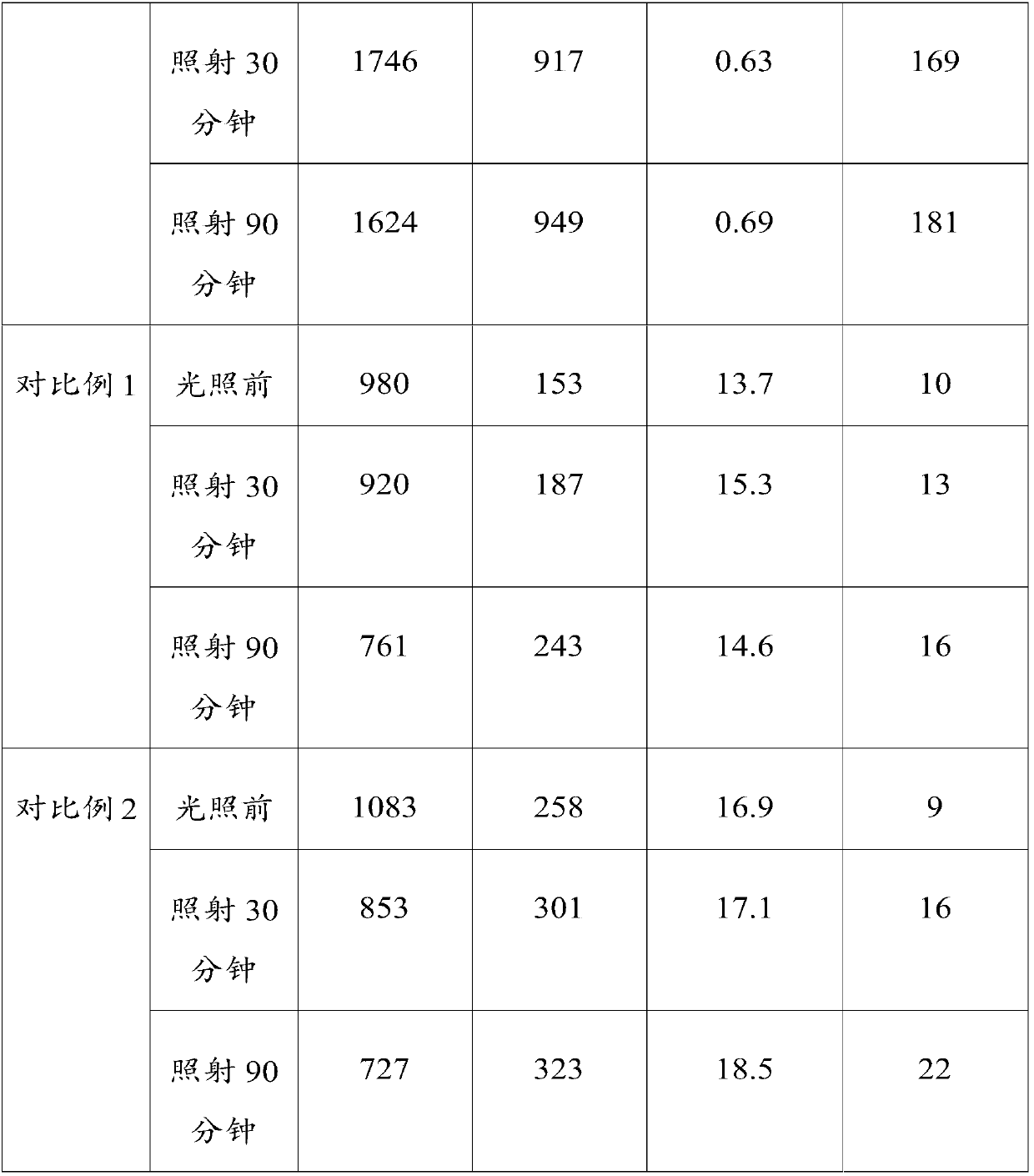

Examples

Embodiment 1

[0041] This embodiment provides a photoconductive material for laser printing, which is made of 1g tungsten carbide powder, 1g nickel, 0.5g silicon dihydroxyphthalocyanine, 1.2g silicon dioxide, 0.5g silicon and 10g resin mixture. Wherein, the resin mixture includes benzimidazole acylhydrazone compounds, polyamide and diphenoquinone.

[0042] This embodiment also provides a method for preparing a photosensitive drum using the photoconductive material for laser printing, comprising the following steps:

[0043] S1. Prepare the first mixture;

[0044] In a protective gas atmosphere, melt 1g of tungsten carbide powder and 1g of nickel at 1000°C, cool the temperature to 800°C, add 1.2g of silicon dioxide and 0.5g of silicon and melt for 1 hour, and then melt the first mixture The melt was cooled to 200°C.

[0045] S2, preparing the second mixture;

[0046] Mix 0.5g of dihydroxyphthalocyanine silicon and 10g of resin mixture with solvent to obtain the second mixture. The mass ra...

Embodiment 2

[0050] This embodiment provides a photoconductive material for laser printing, which is made of 5g tungsten carbide powder, 3g nickel, 1.3g silicon dihydroxyphthalocyanine, 1.8g silicon dioxide, 0.7g silicon and 15g resin mixture. Wherein, the resin mixture includes benzimidazole acylhydrazone compounds, polycarbonate and diphenoquinone.

[0051] This embodiment also provides a method for preparing a photosensitive drum using the photoconductive material for laser printing, comprising the following steps:

[0052] S1. Prepare the first mixture;

[0053] In a protective gas atmosphere, melt 5g of tungsten carbide powder and 3g of nickel at 1200°C, cool the temperature to 950°C, add 1.8g of silicon dioxide and 0.7g of silicon for 2 hours, and then melt the first mixture The melt was cooled to 300°C.

[0054] S2, preparing the second mixture;

[0055] Mix 1.3g of dihydroxyphthalocyanine silicon and 15g of resin mixture with solvent to obtain the second mixture, the mass ratio ...

Embodiment 3

[0059] This embodiment provides a photoconductive material for laser printing, which is made of 2g tungsten carbide powder, 1.5g nickel, 0.7g silicon dihydroxyphthalocyanine, 1.4g silicon dioxide, 0.6g silicon and 11g resin mixture. Wherein, the resin mixture includes benzimidazole acylhydrazone compounds, polyimide and diphenoquinone.

[0060] This embodiment also provides a method for preparing a photosensitive drum using the photoconductive material for laser printing, comprising the following steps:

[0061] S1. Prepare the first mixture;

[0062] In a protective gas atmosphere, melt 2g of tungsten carbide powder and 1.5g of nickel at 1100°C, cool the temperature to 900°C, add 1.4g of silicon dioxide and 0.6g of silicon and melt for 1.5 hours, and then the first mixture The melt was cooled to 250 °C.

[0063] S2, preparing the second mixture;

[0064] Mix 0.7g of dihydroxyphthalocyanine silicon and 11g of resin mixture with solvent to obtain the second mixture, the mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com