Polymer alloy circulation mixing device

A polymer mixing technology, applied in the field of polymer alloy circulation mixing equipment, can solve the problems of long-term thermomechanical action of polymer composite materials, high material property dependence, poor quality of extruded products, etc., to achieve mixing Reliable work, good molding quality and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

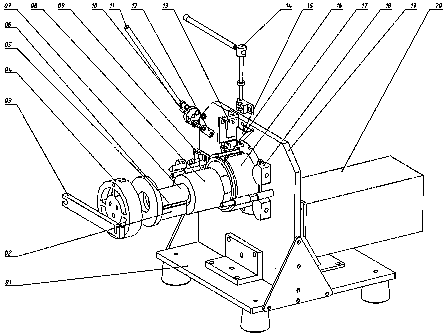

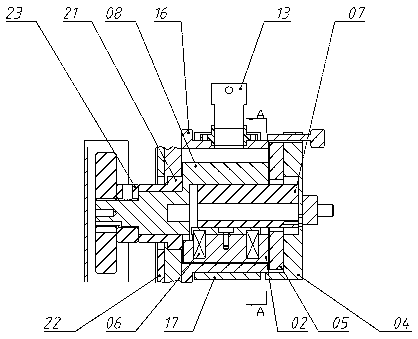

[0020] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention is not limited to the range expressed in the examples.

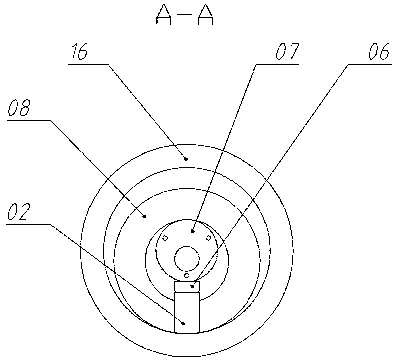

[0021] For reference, the present invention provides a kind of cyclic stretching equipment that can be used for melting and mixing polymers. It uses the eccentricity between the adjustment barrel 16 and the hollow rotor to generate a controllable stretching force field. With the hollow rotor 8, the push plate 2 on the hollow rotor 8 is always tightly attached to the inner wall of the barrel 16 under the action of the cam 7 and the spring 6, and the polymer nanocomposite material is forced to melt, plasticize, disperse and mix, specifically including the following step:

[0022] Along the chute between the limit pressure block 18 and the guide rail 25, slide the material cylinder 16 and the hollow rotor 8 to form a certain eccentric distance, then fix th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap