Graphene anticorrosion coating and preparation method thereof

A technology of anti-corrosion coatings and graphene, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problem that anti-corrosion coatings are difficult to meet high temperature and high humidity resistance, acid rain resistance, salt spray resistance, poor corrosion resistance, outdoor steel structures Problems such as poor use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

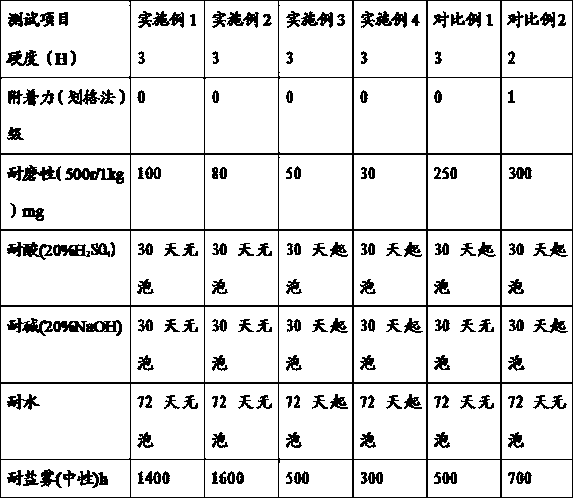

Embodiment 1

[0049] Embodiment 1: a kind of graphene anticorrosion coating, used raw material is as follows:

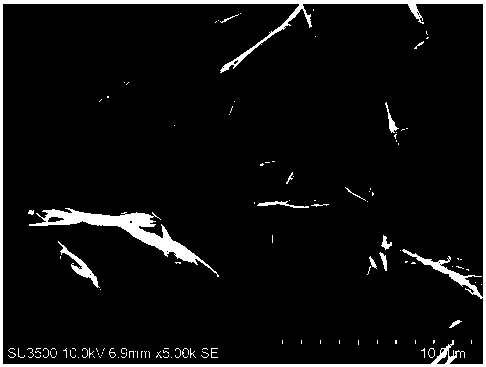

[0050] The graphene self-repairing anticorrosion primer includes the following raw materials in parts by weight: 6 parts of E44 epoxy resin, 16 parts of E20 epoxy resin, 14 parts of 650 polyamide curing agent, 0.5 part of graphene, 5 parts of 800 mesh zinc phosphate, 30 parts of 500 mesh zinc powder, 3.7 parts of 1000 mesh mica powder, nano-SiO 2 1.0 copies, BENGEL ® 1.0 parts of 828 organic bentonite, 4 parts of xylene, 8 parts of n-butanol, 6 parts of cyclohexanone, 1.5 parts of H-1400, 2.0 parts of BYK110, 1.0 parts of 6900-20X, 0.3 parts of 5500 defoamer. Among them, the diameter of graphene sheets is 5-30um, the number of graphene layers is less than 10 layers, and the specific surface area of graphene is 30-200m 2 / g.

[0051] Paint preparation process: provide graphene slurry. Among them, the graphene slurry is prepared; the flake graphite with a purity of 97-99% is o...

Embodiment 2

[0056] Embodiment 2: The graphene anticorrosion coating comprises the following raw materials in parts by weight: 6 parts of E44 epoxy resin, 16 parts of E20 epoxy resin, 14 parts of 650 polyamide curing agent, 1 part of graphene, 5 parts of 800 mesh zinc phosphate , 30 parts of 500 mesh zinc powder, 3.2 parts of 1000 mesh mica powder, nano-SiO 2 1.0 copies, BENGEL ® 1.0 parts of 828 organic bentonite, 4 parts of xylene, 8 parts of n-butanol, 6 parts of cyclohexanone, 1.5 parts of H-1400, 2.0 parts of BYK110, 1.0 parts of 6900-20X, 0.3 parts of 5500 defoamer. Among them, the diameter of graphene sheets is 5-30um, the number of graphene layers is less than 10 layers, and the specific surface area of graphene is 30-200m 2 / g.

[0057] Coating preparation technological process is with embodiment 1

Embodiment 3

[0059] The graphene anticorrosion coating includes the following raw materials in parts by weight: 6 parts of E44 epoxy resin, 16 parts of E20 epoxy resin, 14 parts of 650 polyamide curing agent, 3 parts of graphene, 5 parts of 800 mesh zinc phosphate, 500 mesh zinc 28 parts of powder, 3.2 parts of 1000 mesh mica powder, nano-SiO 2 1.0 copies, BENGEL ® 1.0 parts of 828 organic bentonite, 4 parts of xylene, 8 parts of n-butanol, 6 parts of cyclohexanone, 1.5 parts of H-1400, 2.0 parts of BYK110, 1.0 parts of 6900-20X, 0.3 parts of 5500 defoamer. Among them, the diameter of graphene sheets is 5-30um, the number of graphene layers is less than 10 layers, and the specific surface area of graphene is 30-200m 2 / g.

[0060] Coating preparation technological process is with embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com