Glass fiber impregnating compound preparation automatic control system

An automatic control system and glass fiber technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve problems such as unstable product quality, unstable sizing production, loss of economic benefits, etc., to achieve The effect of reducing the labor intensity of workers, reducing the number of operators, and increasing benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

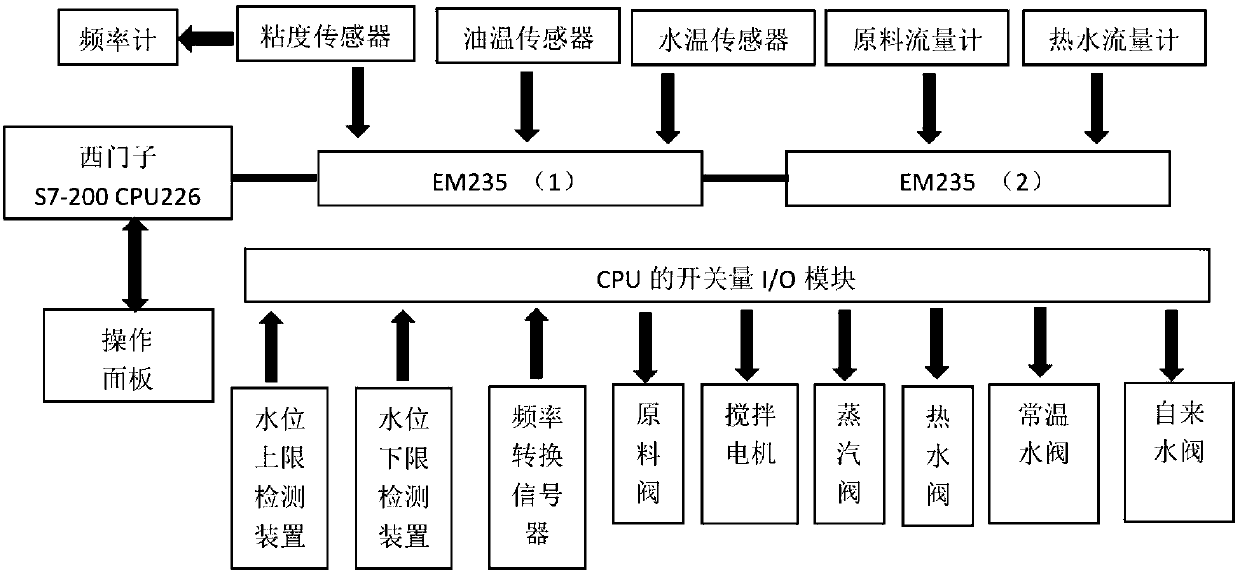

[0015] Such as figure 1 As shown, the glass fiber sizing agent preparation automatic control system of the present invention includes a controller, and the controller is externally connected to an analog input and output module. Sensors, oil temperature sensors, water temperature sensors, raw material flowmeters and hot water flowmeters, viscosity sensors are externally connected to frequency meters, and the input end of the controller switch I / O module is externally connected to water level upper limit detection devices, water level lower limit detection devices and frequency conversion signal devices , can detect the water level and temperature of the water tank, the viscosity of the wetting agent liquid, the temperature of the wetting agent, etc., the output end of the switch value I / O module of the controller is externally connected with a raw material valve, a stirring motor, a steam valve, a hot water valve, and a normal temperature water valve As well as the tap water v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com