A Method of In-Machine Tool Setting for Right Angle Head of CNC Machine Tool

A technology of CNC machine tools and degree head machines, which is applied in digital control, program control, electrical program control, etc. It can solve the problems affecting the automatic processing ability of machine tools, the inability to realize tool setting in the machine, and the difficulty in using the angle head, so as to improve automation. The effect of processing capacity, improving machine tool utilization, high economic and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

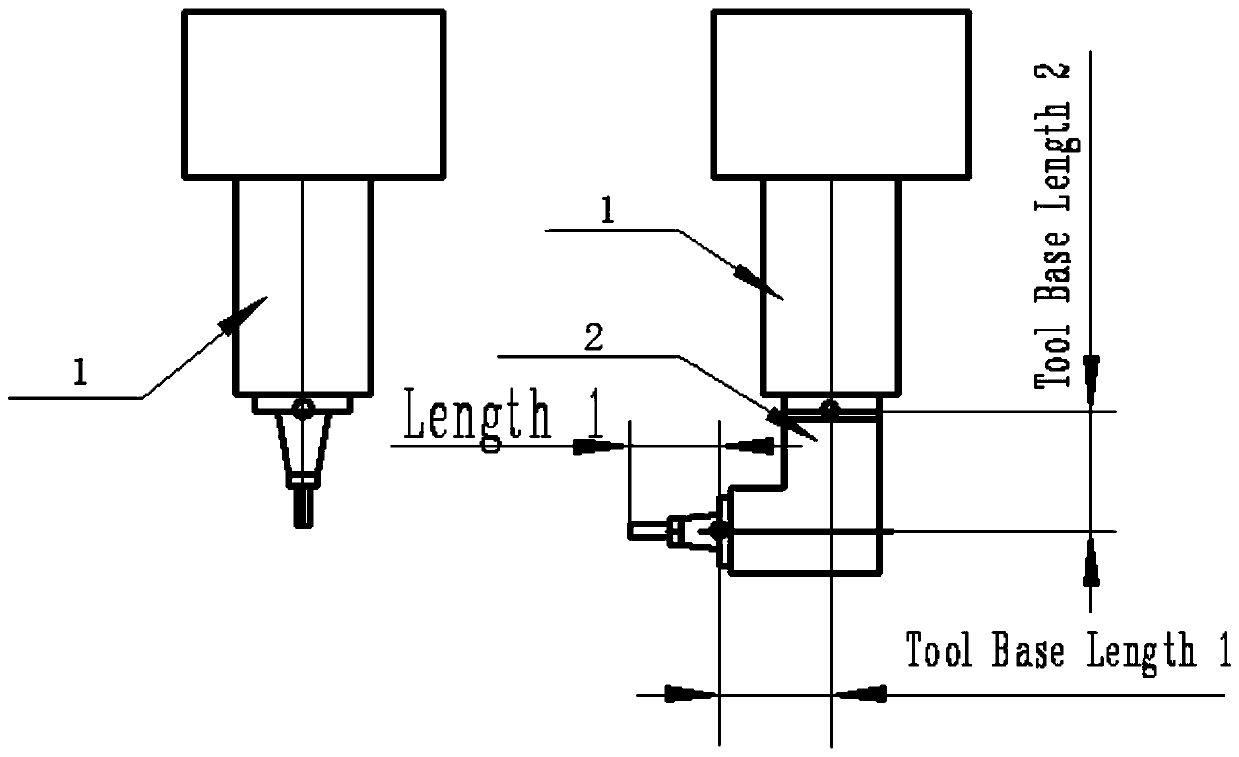

[0015] This embodiment takes the horizontal machining center of the Siemens system as an example for illustration. The program programming adopts the machine tool coordinate system. When the spindle is in a vertical state (after being suspended by 90 degrees), the clamping direction of the angle head tool is the same as that of the spindle (see figure 1 ) or vice versa. Input approximate tool length Length1 and tool radius in advance.

[0016] The steps of the right-angle head tool setting method in the machine are as follows:

[0017] The first step is to install the tool setting standard with the spindle, horizontally calibrate the position of the tool setting laser beam in the machine, and record the Y and Z coordinates of the center position of the laser beam after calibration. This position coordinate value can be passed through the tool setting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com