Method for controlling concentration of ammonia gas in breeding house

A technology of ammonia concentration and control method, which is applied in the direction of ratio control, non-electric variable control, control/regulation system, etc., and can solve the problem of inability to remove ground soil pathogenic bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Select 4 farms in the United States, 4 chicken houses / farms, and use acidifier NaHSO 4 Before, the average outdoor temperature of the two farms was -6°C, and that of the other two was 10°C. In each farm, two houses are used as the acidifier test group, and the addition amount is 25kg / 100m 2 ; The other two groups were the control group, and the litter was not treated. The area of all chicken houses is equal to 12.9mX152m. When the acidulant is applied, the indoor temperature is 32°C, and the litter temperature is 26-30°C. The service cycle of litter ponds in each farm is 2-13 groups.

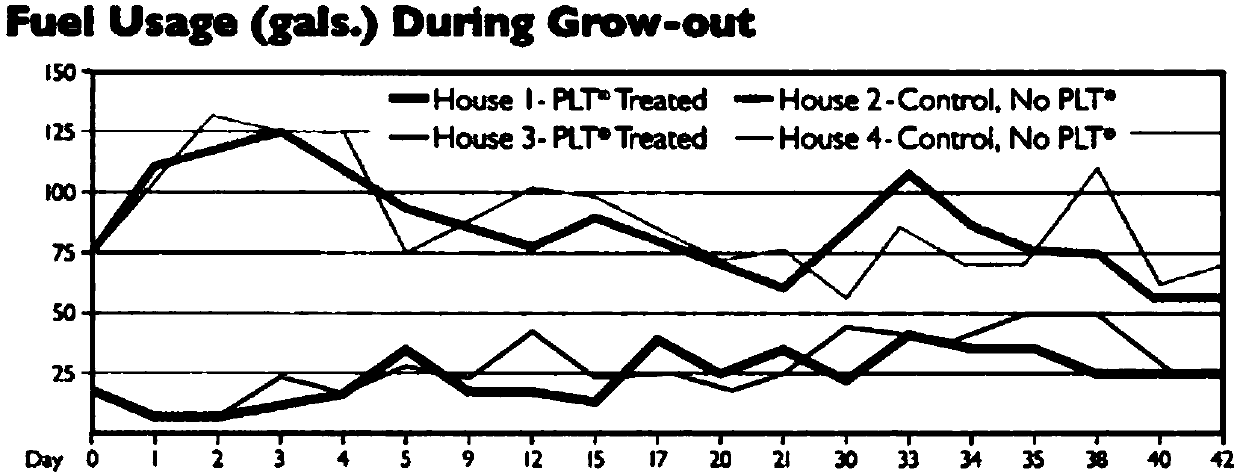

[0072] Such as figure 1 As shown, the test results: Compared with the control group, the average energy consumption of the chicken house using the acidifier was $783, ($1.25 / gallon of propane)

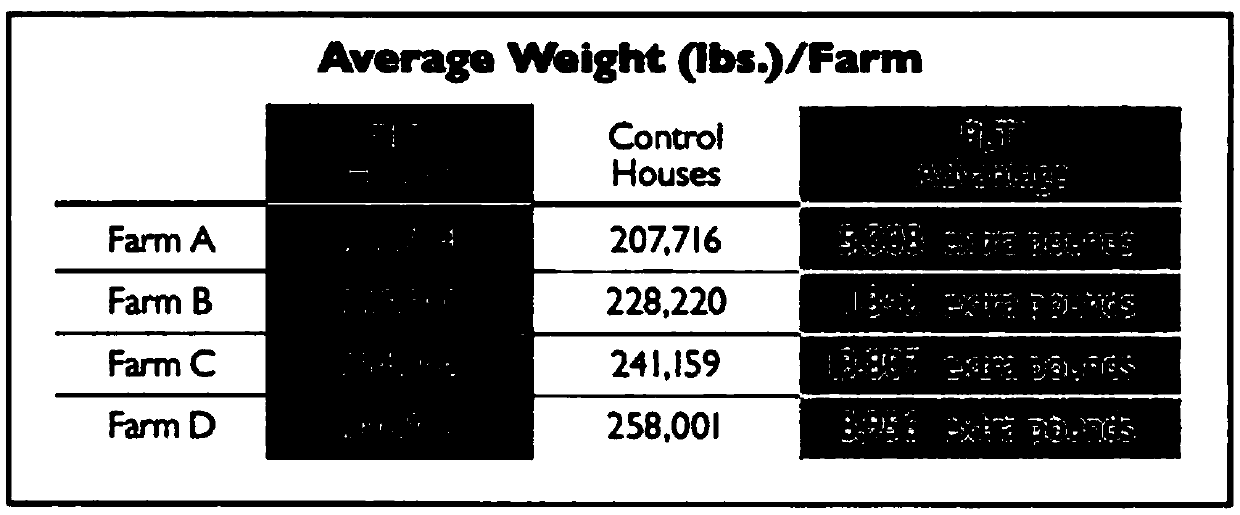

[0073] Such as figure 2 As shown, compared with the control group, the chickens in the group applying the acidulant only had significant weight gain. The flock can use more energy to gro...

Embodiment 2

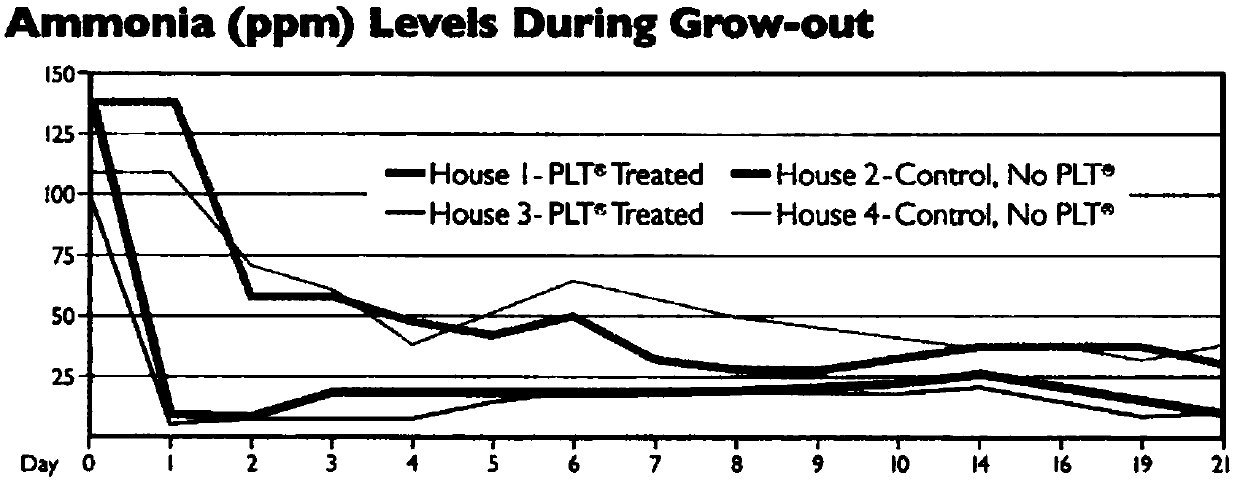

[0077] Two addition ratios of acidifier NaHSO were carried out on 4 farming farms in the United States: 2 northern farms and 2 southern farms 4 , the dosage is respectively: 24.5kg / 100㎡ and 49kg / 100㎡. Before use, the ammonia gas value of the two northern farms was 120ppm, the ammonia gas value of one southern farm was 160ppm, and the ammonia gas value of the other southern farm was 300ppm, and the acidifier NaHSO was applied at 24.5kg / 100㎡ 4 Afterwards, the ammonia value in the northern farm dropped to 41.5ppm, and the acidifier NaHSO was applied at 49kg / 100㎡ 4 The northern farm ammonia value dropped to 31.5ppm. In the application of 24.5kg / 100㎡ acidifier NaHSO 4 Afterwards, the ammonia value of the southern farm dropped to 26.3ppm, and the ammonia value of the southern farm where 49kg / 100㎡ of acidifier was applied dropped to 24ppm. Such as Figure 5 shown.

Embodiment 3

[0078] Embodiment 3 (broiler litter test)

[0079] Chicken house area: 2000㎡, number of broilers: 20,000, litter thickness: 2-3cm, original litter replacement frequency: 10 days / time, test cycle: 100 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com