Housing with fluid duct

A shell and channel technology, applied in the field of shells, can solve problems such as re-locking and achieve the effect of flexible assembly sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

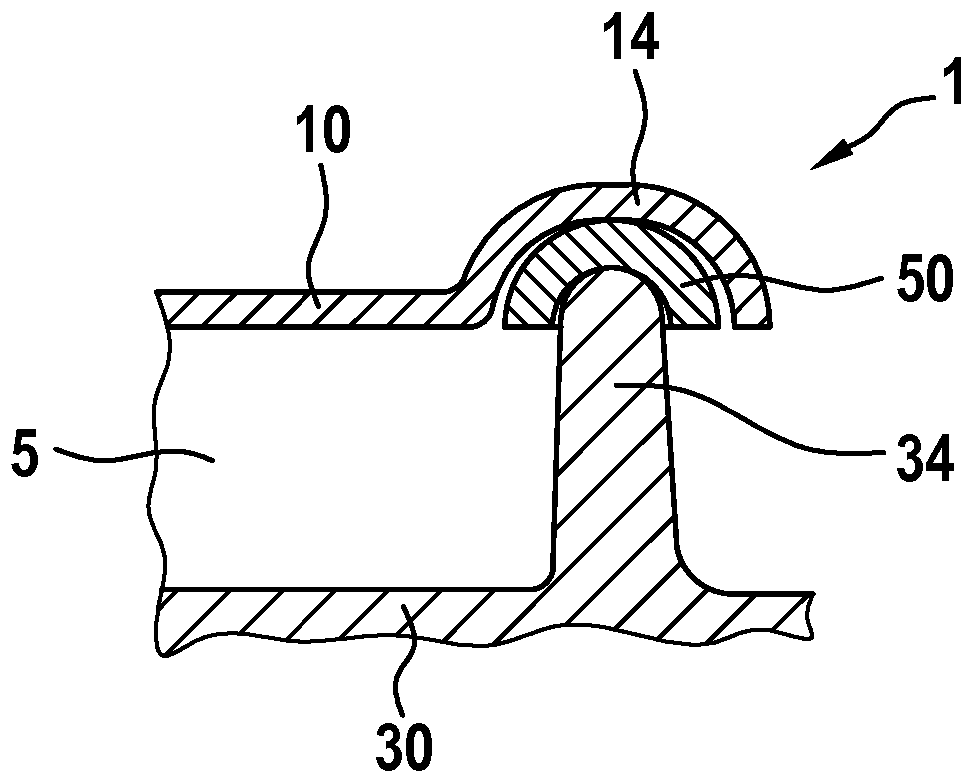

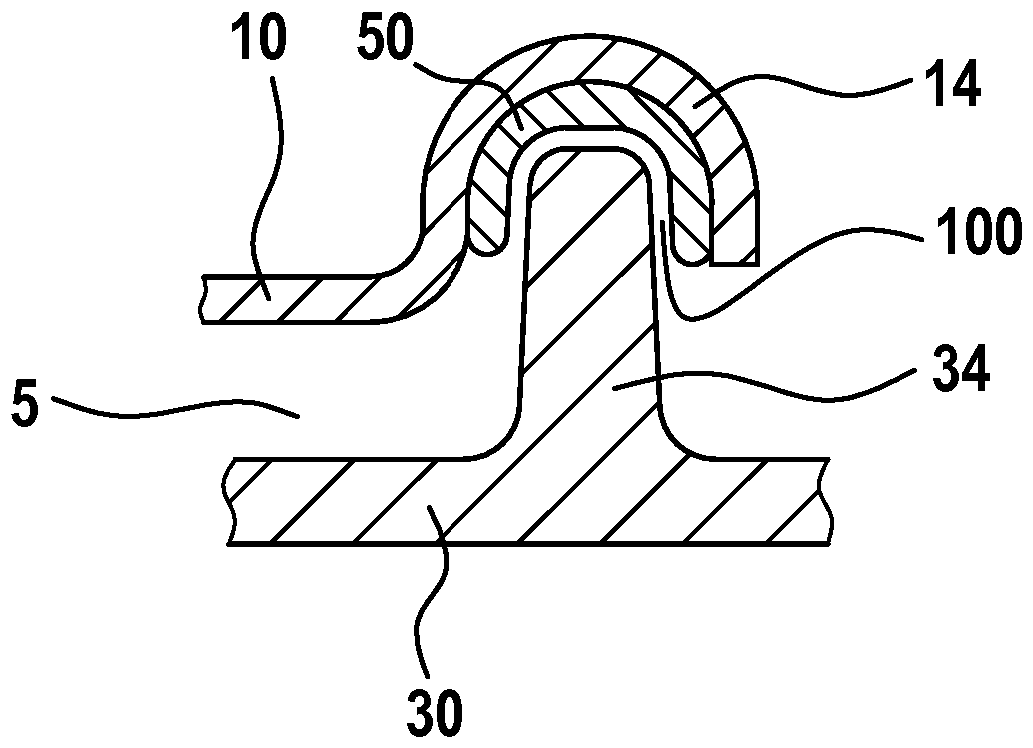

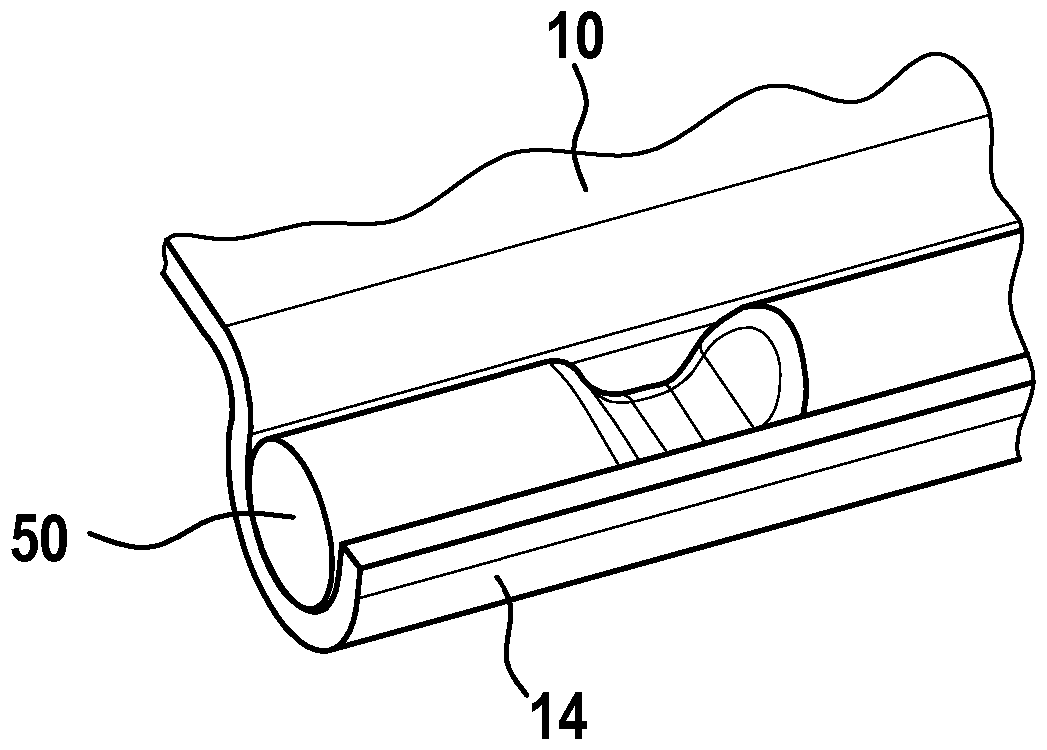

[0031] exist figure 1 A top view of the housing 1 is shown in . The housing 1 comprises a first housing element 10 and a second housing element 30 . The first housing element 10 is preferably designed as a deep-drawn part. The configuration as a deep-drawn part enables an easy and cost-effective production of the first housing element 10 . The second housing element 30 is preferably produced by means of die-casting technology, in particular as an aluminum or magnesium die-cast part. In particular, housing 1 is designed to accommodate electrical components, in particular circuit boards. In particular, the printed circuit board can form a control unit of the electric drive. Preferably, the circuit board forms an electrical control unit for a fan motor, in particular a fan motor or a pump of an HVAC system. The second housing element 30 has a cooling body whose main function is to dissipate heat generated during operation of the electrical components. The second housing ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com