Multifunctional emulsification device for producing powder grease

An emulsification device, powder oil technology, applied in mixers with rotating stirring devices, transportation and packaging, chemical instruments and methods, etc., can solve the problems of simple structure, inability to control temperature, stirring time, stirring intensity, affecting emulsion viscosity, Stability and other issues, to achieve the effect of improving quality, delicate ductility, and luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

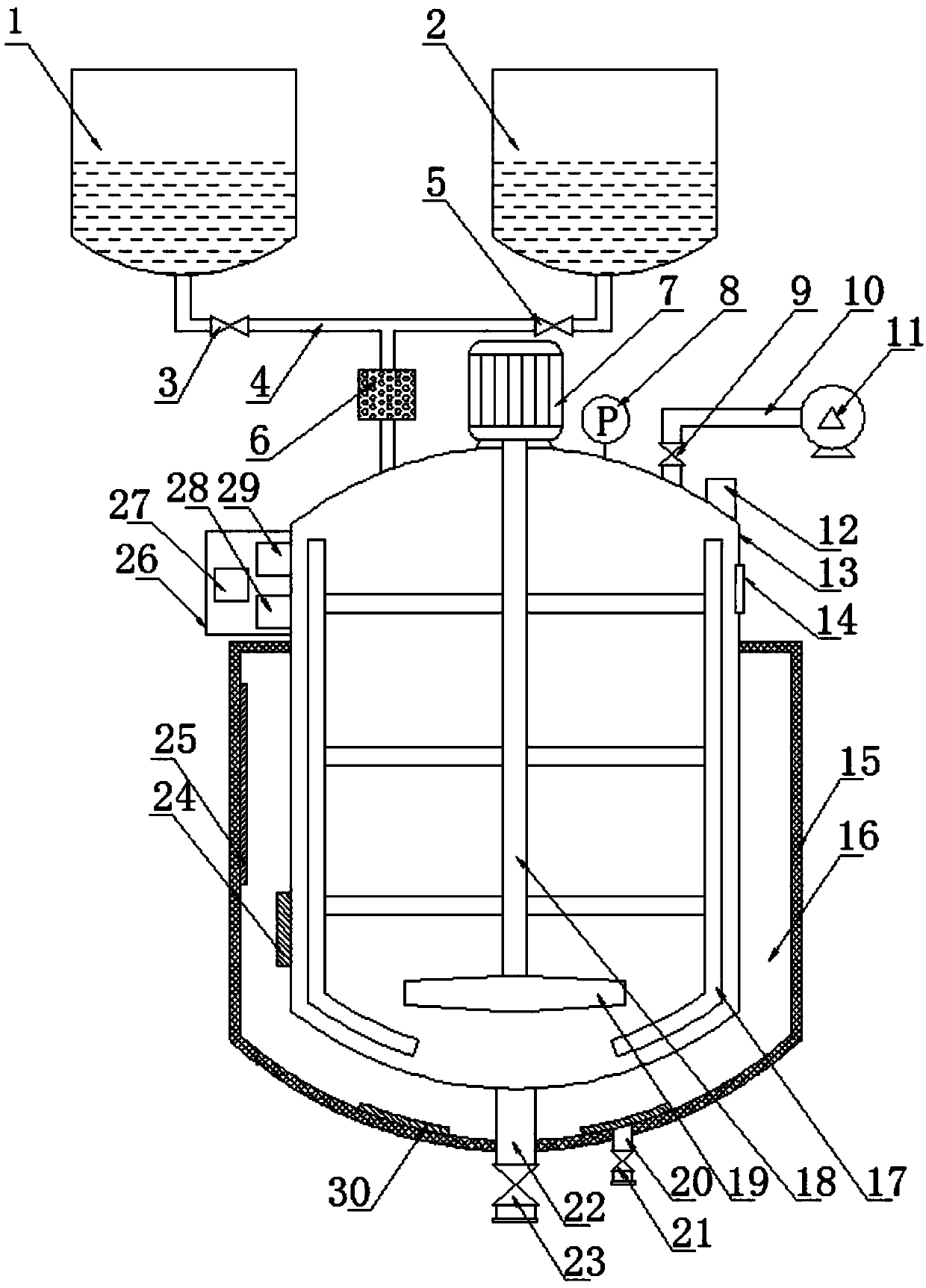

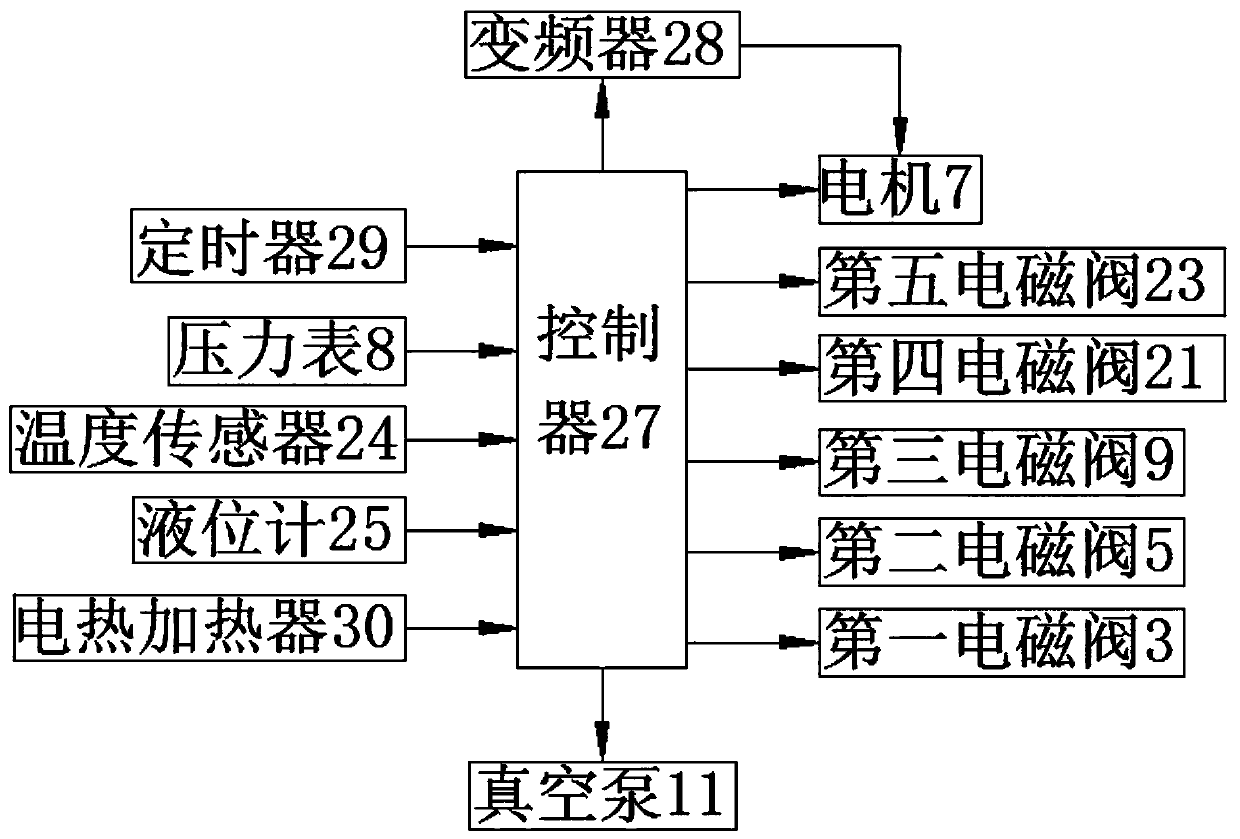

[0011] Embodiment 1, as Figure 1-2 As shown, a multi-functional emulsification device for producing powdered oil comprises a water pot 1, an oil pot 2, and an emulsification tank 13; wherein: the bottoms of the water pot 1 and the oil pot 2 are connected with a first water pipe 4, and the water pot 1 is connected to the first solenoid valve 3 through the first water pipe 4, the oil pan 2 is connected to the second solenoid valve 5 through the first water pipe 4, the first water pipe 4 is connected to the filter 6, and the filter 6 is connected to the emulsifying valve through the first water pipe 4. The tank body 13 is connected, the top of the emulsification tank body 13 is equipped with a motor 7, the motor 7 is coaxially connected with the rotating shaft 18, the bottom end of the rotating shaft 18 is coaxially connected with the stirring paddle 19, and scrapers 17 are connected on both sides of the rotating shaft 18, and the emulsifying tank body 13 A pressure gauge 8 and ...

Embodiment 2

[0012] Embodiment 2. A multifunctional emulsification device for producing powdered oil, wherein: the water pot 1 contains water-soluble raw materials, and the oil pot 2 contains oil-soluble raw materials. All the other are with embodiment 1.

[0013] working principle:

[0014] The water pot 1 is equipped with a water-soluble raw material mixture, and the oil pan 2 is equipped with an oil-soluble raw material mixture. The controller 27 controls the third solenoid valve 9 to open, and at the same time controls the vacuum pump 11 to start, and the vacuum pump 11 extracts the emulsification tank 13 The air in the emulsification tank 13 gradually reaches a vacuum state. The pressure gauge 8 detects the vacuum degree in the emulsification tank 13 in real time. When the emulsification tank 13 reaches the water diversion requirement, the controller 27 simultaneously controls the first solenoid 3. The second solenoid valve 5 is opened, and the raw material mixture in the water pot 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com