Cross contamination-resistant circulating microencapsulation high-pressure homogenizer

A high-pressure homogenizer and microencapsulation technology, used in mixers, mixer accessories, chemical instruments and methods, etc., can solve the problem of inability to obtain a uniform particle emulsion, and achieve the effect of fine taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

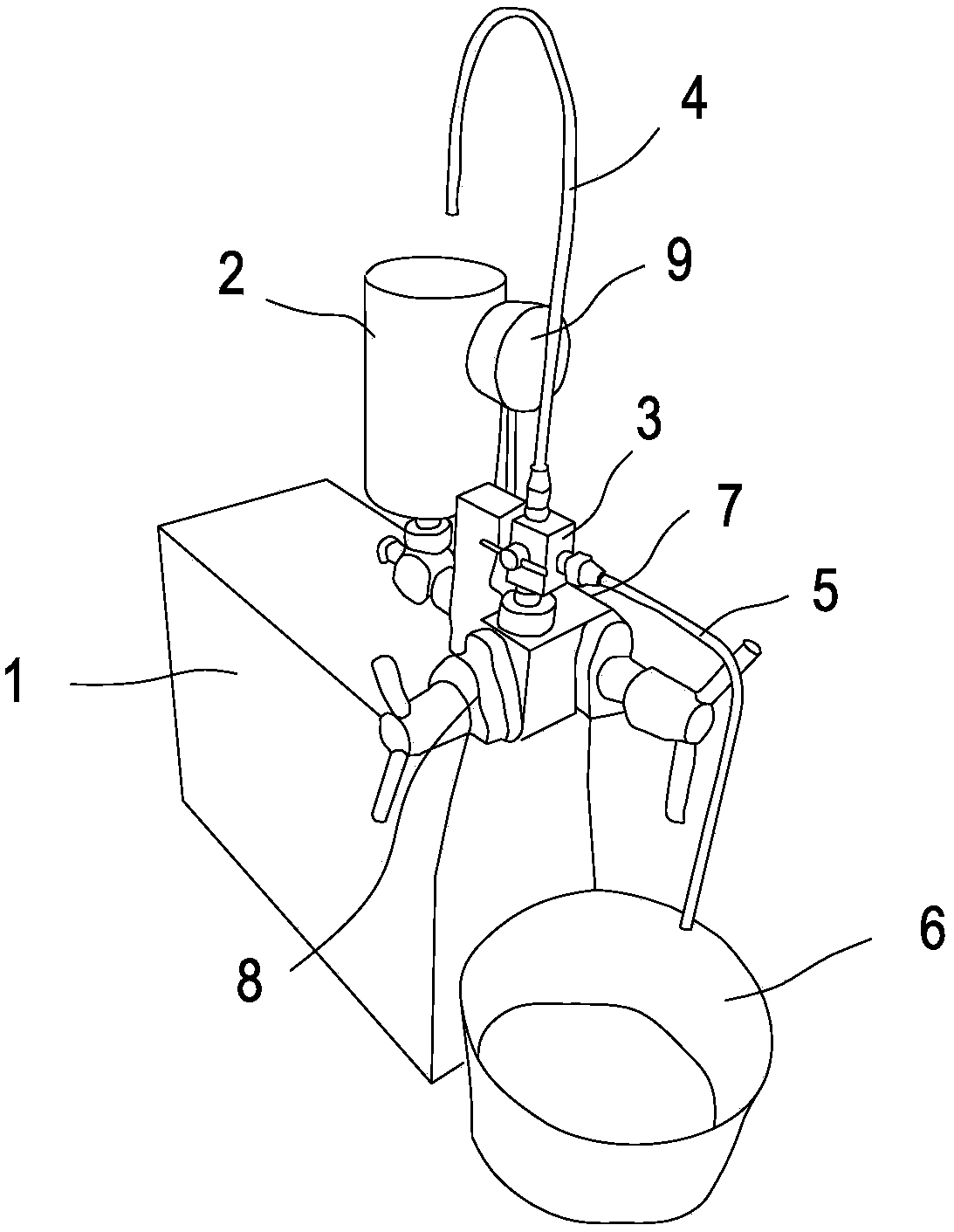

[0028] Such as image 3 As shown, a high-pressure homogenizer of microencapsulation anti-cross-feed circulation type includes a homogenizing pump 1, and the homogenizing pump 1 is provided with a homogenizing feeding cylinder 2, and the homogenizing feeding cylinder 2 is connected to the homogenizing pump 1 feed port, the homogeneous pump 1 discharge port is connected to the homogeneous feed cylinder 2, the homogeneous pump 1 discharge port is provided with a three-way switch valve 3, and the three-way switch valve 3 is connected with a backflow Pipe 4 and discharge pipe 5, the return pipe 4 is connected to the homogeneous feeding cylinder 2, and the discharge pipe 5 is connected to the homogeneous liquid storage tank 6.

[0029] The feed port of the homogenizing pump 1 of the existing homogenizer is connected to the homogenizing feeding barrel 2, and after the material is homogenized by the homogenizing pump 1 under high pressure, it is directly returned to the homogenizing f...

Embodiment 2

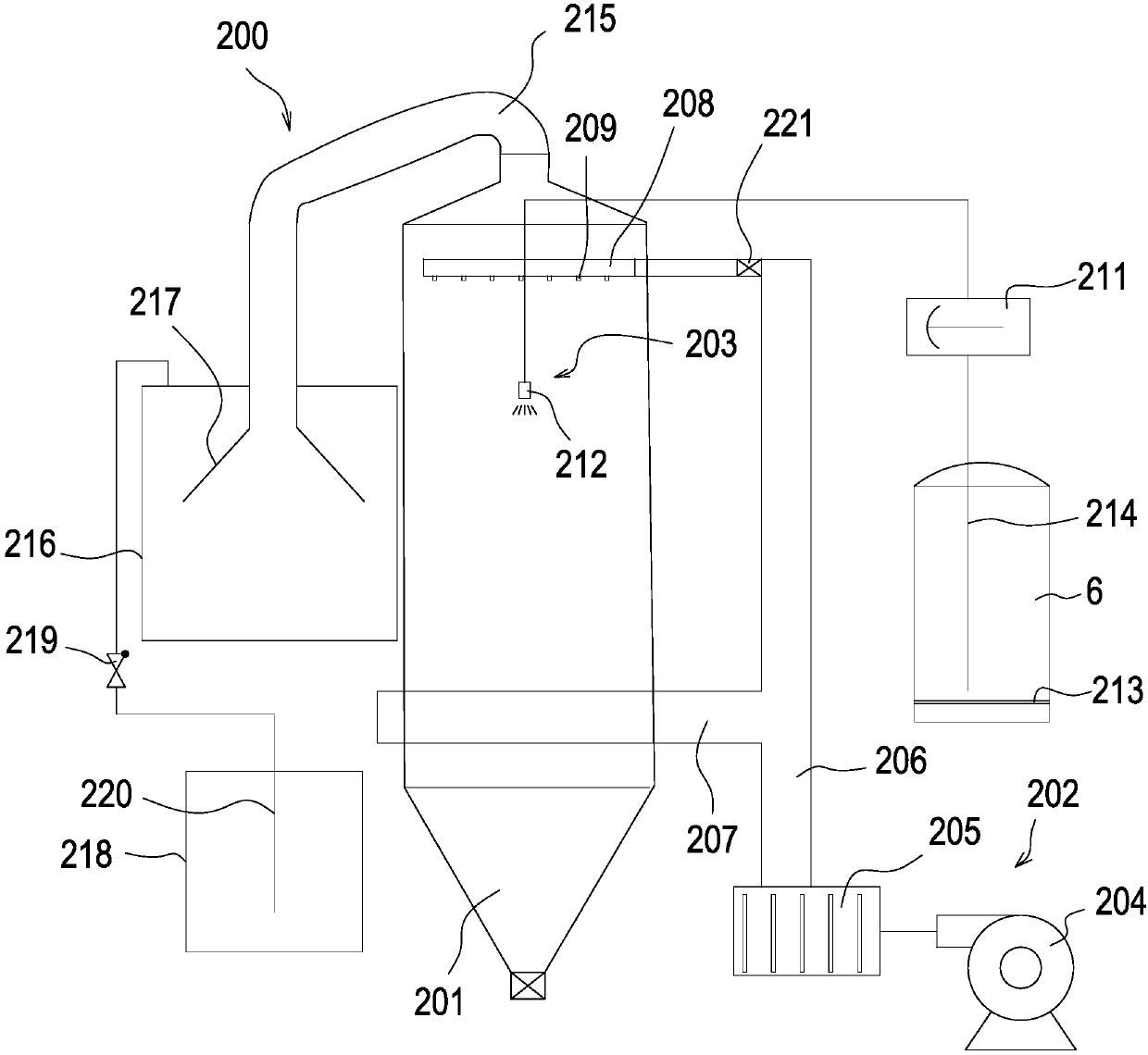

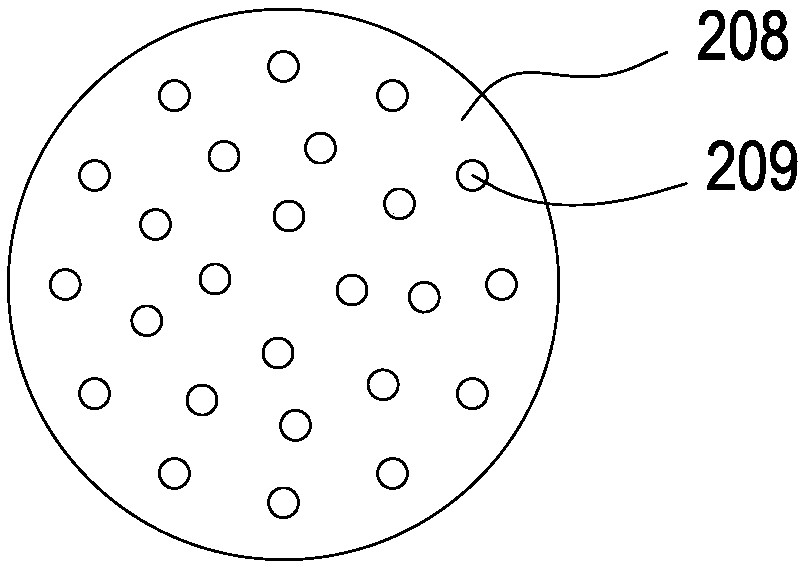

[0033] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as figure 1 As shown, a high-pressure homogenizer of microencapsulation anti-crossover circulation type includes a tower body 201, the side wall of the tower body 201 is connected with a hot air inlet assembly 202, and the top of the tower body 201 is connected with an air outlet assembly 200, the tower body 201 is provided with a spray assembly 203, the hot air inlet assembly 202 includes a hot air blower 204, and a heater 205 connected to the hot air blower 204, the heater 205 is connected to the main air inlet pipe 206, and the main air inlet The air duct 206 is connected to the side air inlet pipe 207, and the side air inlet pipe 207 is connected to the side wall of the tower body 201. The main air inlet pipe 206 is also connected to the pressure stabilizing plate 208, and the pressure stabilizing plate 208 is located in the spray assembly 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com