Washing system for washing U-shaped porous glass plate absorption tube

A multi-hole glass plate and cleaning system technology, applied in the field of circulating cleaning systems, can solve the problems of long-term cleaning, waste of time and manpower, troublesome cleaning operations, etc., and achieve the effects of short cleaning cycle, thorough cleaning and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

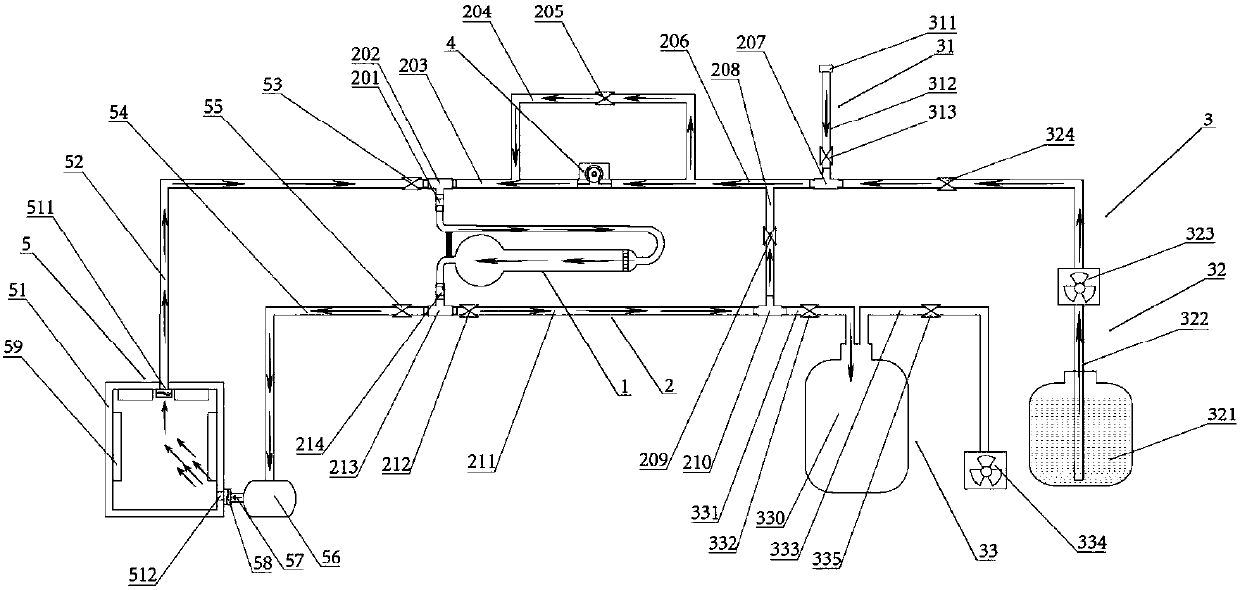

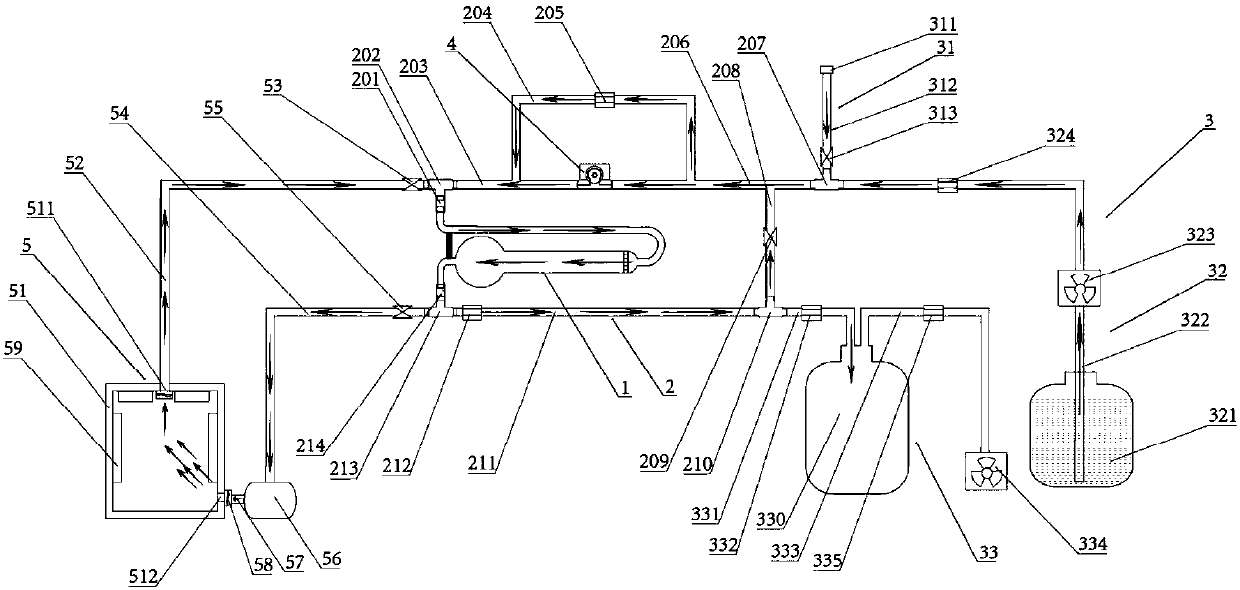

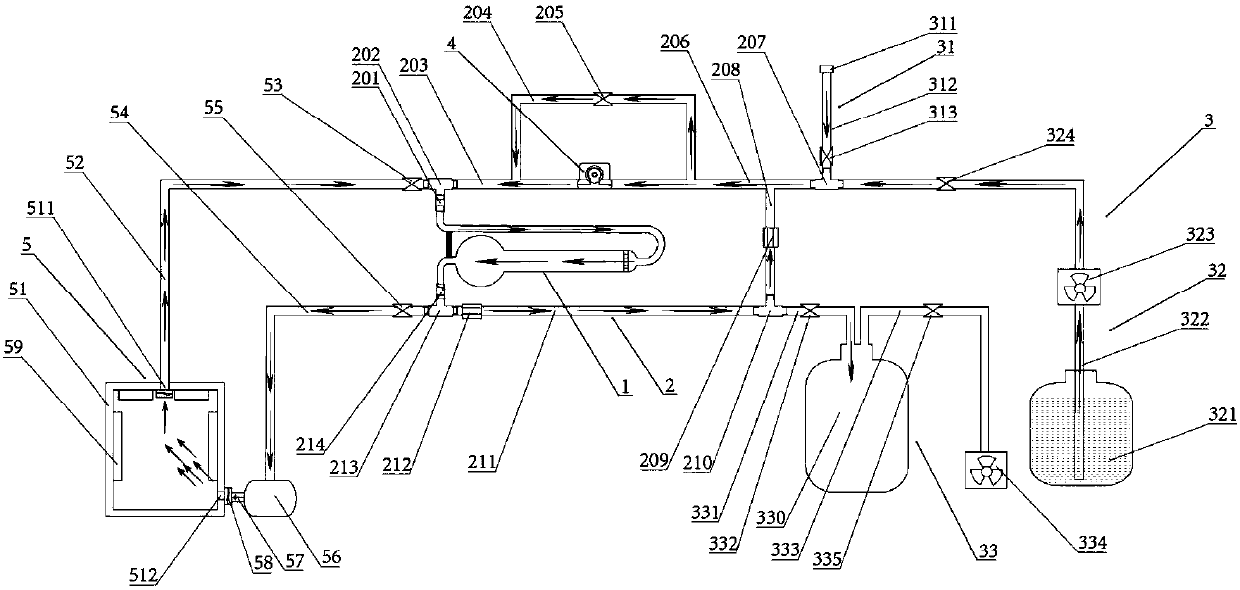

[0021] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

[0022] like Figure 1 to Figure 6 As shown, the cleaning system for cleaning the U-shaped porous glass plate absorption tube of the present invention includes a U-shaped porous glass plate absorption tube 1, a flow guide system 2, a liquid supply and liquid collection system 3, a peristaltic pump 4, an air-drying System 5, timing module, liquid level sensor and PLC controller, wherein:

[0023] The U-shaped porous glass plate absorption tube 1 is arranged on the support (not shown in the figure) on the operating table, and the flow guide system 2 is used to realize the communication with the U-shaped porous glass plate absorption tube to form a liquid guiding channel that communicates with each other. Loop to clean the U-shaped multi-well glass plate absorber tube with liquid. The diversion sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com