Technology of high-strength dual-phase steel sheet welded by high-speed laser wire filling welding

A technology of laser wire filling and dual-phase steel, applied in laser welding equipment, welding medium, welding equipment, etc., can solve problems such as softening of welding zone

- Summary

- Abstract

- Description

- Claims

- Application Information

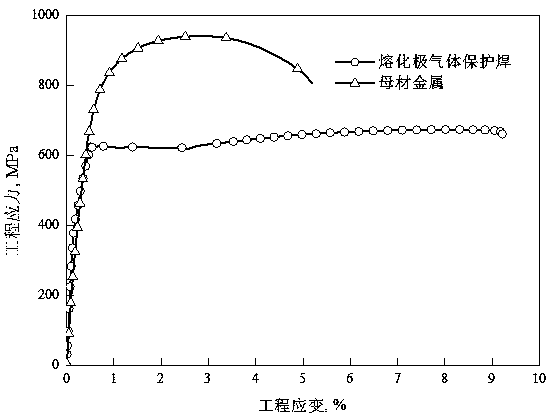

AI Technical Summary

Problems solved by technology

Method used

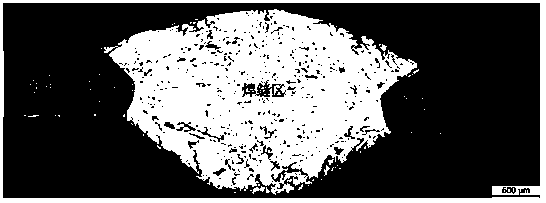

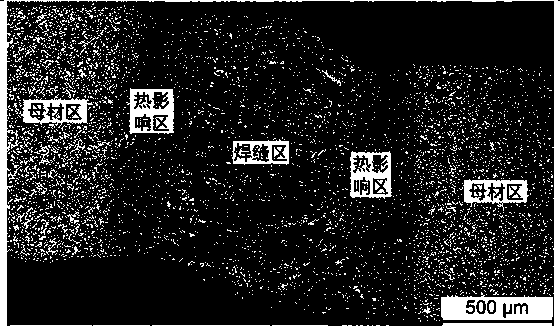

Image

Examples

Embodiment 1

[0031] The steel plate used before welding is dual-phase steel, and its composition is listed in Table 1. The thickness of the steel plate is 0.8mm, the steel plate is straight, the surface is clean, and there is no pollutants such as oil stains and water stains. Two duplex steel plates of the same length are fixed on the laser welding tooling table with a welding fixture, and then the butt joint surfaces of the two steel plates are cut out to be parallel to each other by a laser cutting method. With the help of the distance adjustment device of the welding table, the steel plate is moved in parallel to make the prefabricated butt joint gap of 0.22mm. Butt welding with IPG YLS-6000 fiber optic Nd:YAG laser, the defocus distance is +3 mm, the laser power is controlled at 1.8kW, and the welding speed is 24 mm the s -1 . The wire diameter is 0.6mm, and the wire feeding speed is 30mm the s -1 . High-purity argon is used as the shielding gas, the gas supply hose is fixed on...

Embodiment 2

[0035]The steel plate used before welding is dual-phase steel, and its composition is listed in Table 1. The thickness of the steel plate is 1.3 mm, the steel plate is straight, the surface is clean, and there is no pollutants such as oil stains and water stains. Two duplex steel plates of the same length are fixed on the laser welding tooling table with a welding fixture, and then the butt joint surfaces of the two steel plates are cut out to be parallel to each other by a laser cutting method. With the help of the distance adjustment device of the welding table, the steel plate is moved in parallel to make the prefabricated butt joint gap of 0.25 mm. Filled butt welding with IPG YLS-6000 fiber optic Nd:YAG laser, the defocus distance is +3 mm, the laser power is controlled at 2.4 kW, and the welding speed is 26 mm the s -1 . The wire diameter is 0.65 mm and the wire feed speed is 45 mm the s -1 . High-purity argon is used as the shielding gas, the gas supply hose is ...

Embodiment 3

[0037] The steel plate used before welding is dual-phase steel, and its composition is listed in Table 1. The thickness of the steel plate is 1.7 mm, the steel plate is straight, the surface is clean, and there is no pollutants such as oil stains and water stains. Two duplex steel plates of the same length are fixed on the laser welding tooling table with a welding fixture, and then the butt joint surfaces of the two steel plates are cut out to be parallel to each other by a laser cutting method. With the help of the distance adjustment device of the welding table, the steel plate is moved in parallel to make the prefabricated butt joint gap of 0.28 mm. Filled butt welding with IPG YLS-6000 fiber optic Nd:YAG laser, the defocus distance is +1 mm, the laser power is controlled at 3.1 kW, and the welding speed is 40 mm the s -1 . The wire diameter is 0.65 mm and the wire feed speed is 55 mm the s -1 . High-purity argon is used as the shielding gas, the gas supply hose is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com