Micro-blowing structure and method for resistance reducing and lift increasing of supercritical airfoil

A supercritical and airfoil technology, applied in transportation and packaging, affecting the air flow passing through the surface of the aircraft, aircraft parts, etc., can solve the problems of increasing the total resistance instead of decreasing, and making the micro blowing technology unable to apply to large passenger aircraft, etc. Achieve high drag reduction efficiency, increase airfoil lift, and reduce pressure differential resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

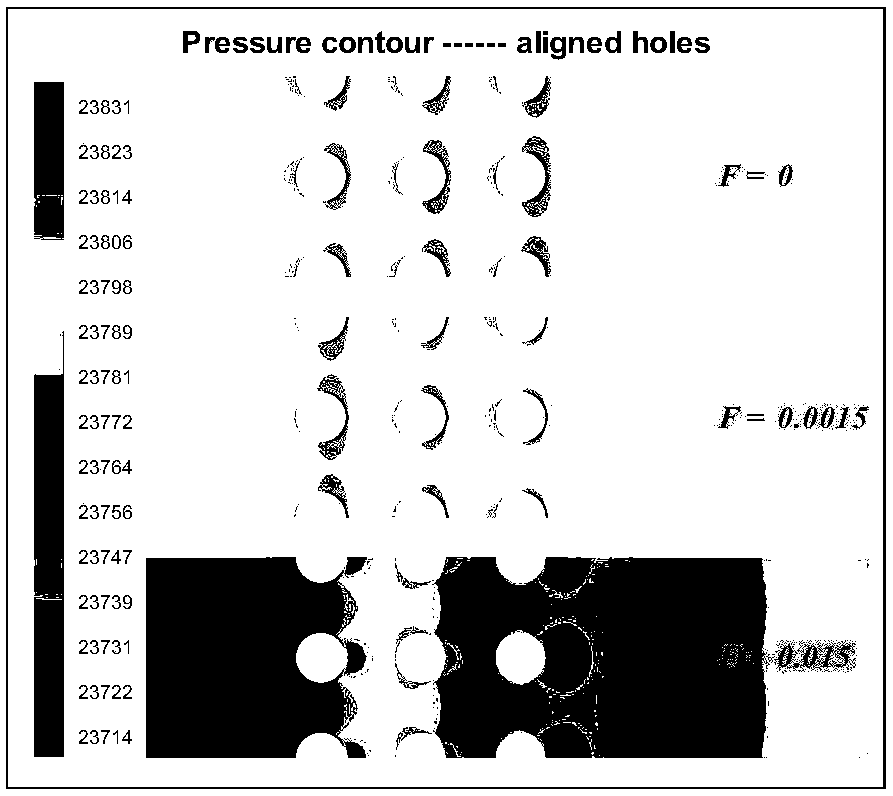

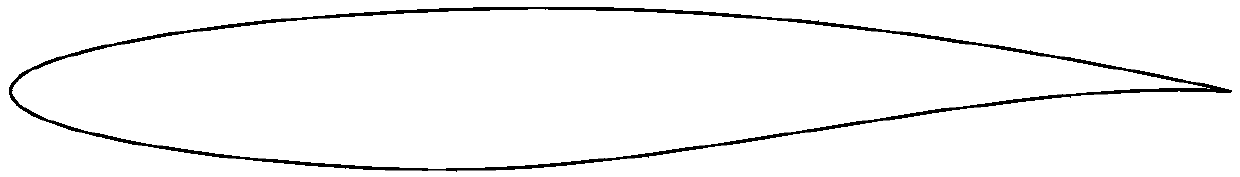

[0027]Example: NASA-PN2 microporous skin is selected, the micropore diameter is 0.165 mm, the skin thickness is 1.02 mm, and the porosity is 23%. The applied airfoil is RAE2822 airfoil, the incoming flow condition is taken as Mach number is 0.734, and the flight altitude is 10.7km. Skin layout schemes such as Figure 5 As shown, the microblown skin is arranged in the 20% chord length area of the trailing edge of the lower airfoil. The blowing fraction is F=0.008~0.5, and the angle of attack range is α=0°~1°. Table 1 shows the drag reduction and lift-increasing effects of the micro-blowing arranged according to the above scheme at different angles of attack and different blowing fractions, where the subscript contains "w" to represent the lift or drag value without micro-blowing, C l 、C lw represent the lift coefficient of the airfoil under micro-blowing and without micro-blowing, respectively, and C d 、C dw are the drag coefficients of the airfoil with micro-blowing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com