Device and method for non-equilibrium catalytic reaction of ethylamine

A technology of catalytic reaction and balanced reaction, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of increased proportion of by-products, increased energy consumption, increased waste discharge, etc., to reduce by-products, reduce Energy consumption, elimination of product cycle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

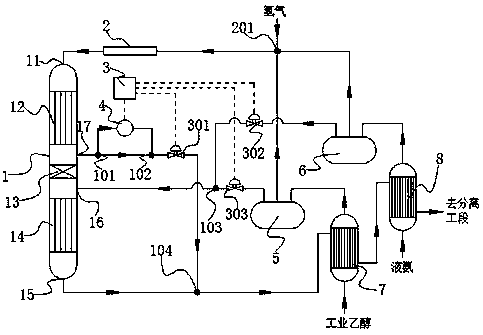

[0020] The device for the non-equilibrium catalytic reaction of ethylamine includes a reactor (1), a static mixer (2), a controller (3), an in-situ infrared spectrum (4), an ethanol vaporization chamber (5), an ammonia vaporization chamber (6), The first heat exchanger (7), the second heat exchanger (8), automatic valve I (301), automatic valve II (302) and automatic valve III (303); There is a reactor inlet (11), a reactor outlet (15) at the lower end, an unbalanced reaction section (12), a rectifying packing (13) and a balanced reaction section (14) are arranged in the inner chamber from top to bottom, and the side is in the non-equilibrium reaction section (14). An intermediate outlet (17) is provided between the equilibrium reaction section (12) and the rectification packing (13), and an intermediate inlet (16) is provided on the side between the rectification packing (13) and the equilibrium reaction section (14); the controller (3 ) is provided with a signal input termin...

Embodiment 2

[0025] In the device for the non-equilibrium catalytic reaction of ethylamine, except that "the diameter of the tube in the non-equilibrium reaction section (12) is Φ57×3.5 mm, and the ratio of height to diameter of the tube is 10", "the catalyst in the non-equilibrium reaction section (12) is A mixture of 50-mesh mordenite and 50-mesh quartz sand, the mass ratio of mordenite to quartz sand in the mixture is 1:10", "the diameter of the tube in the equilibrium reaction section (14) is Φ19×2 mm, the tube The aspect ratio is 200", "the catalyst in the equilibrium reaction section (14) is supported Co / γ-Al 2 o 3 Catalyst, the mass content of Co is 21% " except that all the other contents are identical with embodiment 1.

[0026] In the non-equilibrium catalytic reaction method of ethylamine: except that "the industrial ethanol from the ethanol raw material tank is heated to 130°C through the tube side of the first heat exchanger (7), and then enters the ethanol vaporization chamb...

Embodiment 3

[0028] In the device for the non-equilibrium catalytic reaction of ethylamine, except that "the diameter of the tube in the non-equilibrium reaction section (12) is Φ57×3.5 mm, and the ratio of height to diameter of the tube is 40", "the catalyst in the non-equilibrium reaction section (12) is A mixture of 30-mesh mordenite and 80-mesh quartz sand, the mass ratio of mordenite to quartz sand in the mixture is 1:8", "the diameter of the tube in the equilibrium reaction section (14) is Φ57×3.5 mm, the tube The aspect ratio is 100", "the catalyst in the equilibrium reaction section (14) is supported Co / γ-Al 2 o 3 Catalyst, the mass content of Co is 19% " except that all the other contents are identical with embodiment 1.

[0029] In the non-equilibrium catalytic reaction method of ethylamine: except that "the industrial ethanol from the ethanol raw material tank is heated to 120°C through the tube side of the first heat exchanger (7), and then enters the ethanol vaporization cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com