Waterborne polyurethane for pigment dyeing and preparation method thereof

A water-based polyurethane and paint dyeing technology, which is applied in the direction of polyurea/polyurethane paint, coating, etc., can solve the problems of poor coating fastness of coating materials, unstable polyurethane, and hard hand feeling of coating materials, so as to achieve easy dyeing , good color fastness, little effect on hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

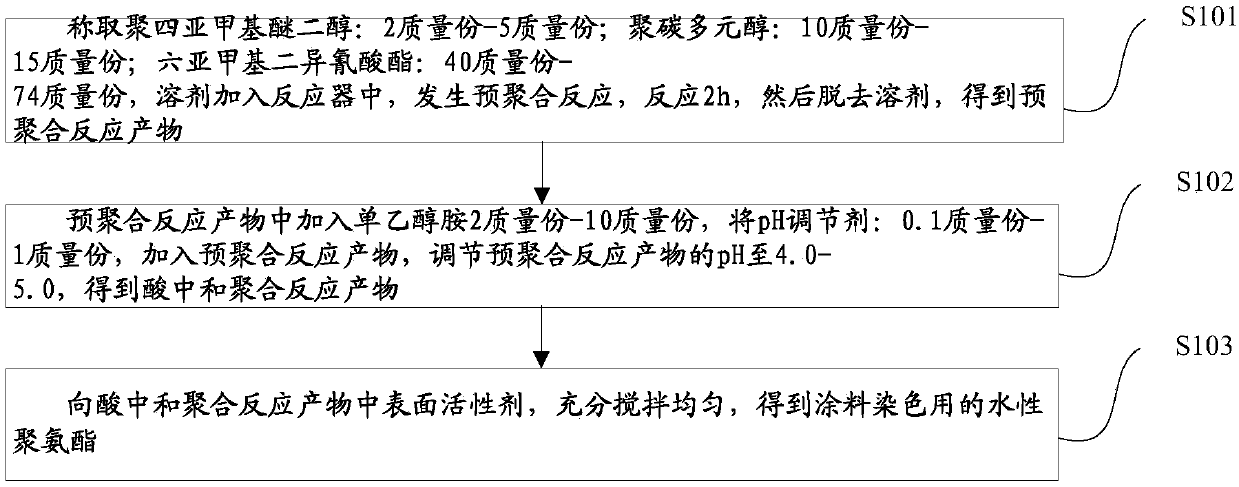

[0036] The second aspect of the embodiment of the present application shows a kind of preparation method of water-based polyurethane for paint dyeing, please refer to figure 1 , the method includes:

[0037] S101 Weigh polytetramethylene ether glycol: 2-5 parts by mass; polycarbonate polyol: 10-15 parts by mass; hexamethylene diisocyanate: 40-74 parts by mass, add solvent In the reactor, a prepolymerization reaction takes place, reacts for 2h, and then removes the solvent to obtain a prepolymerization reaction product;

[0038] S102 Add 2 parts by mass to 10 parts by mass of monoethanolamine to the prepolymerization reaction product, add a pH regulator: 0.1 part by mass to 1 part by mass, add the prepolymerization reaction product, adjust the pH of the prepolymerization reaction product to 4.0-5.0, and obtain the acid Neutralize polymerization reaction products;

[0039] S103 neutralizes the surfactant in the polymerization reaction product with acid, and stirs well to obtai...

Embodiment 1

[0050] Weigh polytetramethylene ether glycol: 2 parts by mass; polycarbonate polyol: 10 parts by mass; hexamethylene diisocyanate: 42 parts by mass, add the solvent into the reactor at a reaction temperature of 80°C, and a prepolymerization reaction occurs. React for 2 hours, then remove the solvent, the temperature for removing the solvent is 120°C, and obtain the prepolymerized reaction product;

[0051] Add 2 parts by mass of monoethanolamine to the prepolymerization reaction product, add a pH regulator: 0.1 part by mass to the prepolymerization reaction product, adjust the pH of the prepolymerization reaction product to 4.0, and obtain an acid neutralization polymerization reaction product;

[0052] Neutralize the surfactant in the polymerization reaction product with the acid, stir well and evenly, and the stirring speed is 1500r / min, and obtain the water-based polyurethane for paint dyeing.

Embodiment 2

[0054] Weigh polytetramethylene ether glycol: 5 parts by mass; polycarbonate polyol: 15 parts by mass; hexamethylene diisocyanate: 74 parts by mass, and add the solvent into the reactor at a reaction temperature of 100°C, and a prepolymerization reaction occurs. React for 2 hours, then remove the solvent, the temperature for removing the solvent is 150°C, and obtain the prepolymerized reaction product;

[0055] Add 10 parts by mass of monoethanolamine to the prepolymerization reaction product, add 1 part by mass of pH regulator to the prepolymerization reaction product, adjust the pH of the prepolymerization reaction product to 4.0-5.0, and obtain an acid neutralization polymerization reaction product;

[0056] S103 neutralizes the surfactant in the polymerization reaction product with the acid, fully stirs evenly, and the stirring rate is 2000r / min, and obtains the water-based polyurethane for paint dyeing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com