Fat particle separation and purification device and fat particle separation and purification method

A technique for separation and purification of fat particles, applied in cell dissociation methods, biochemical cleaning devices, biochemical equipment and methods, etc., can solve problems such as low degree of automation, infection, and unsealed treatment process, and improve the survival rate of fat , reduce inflammatory response, enhance the effect of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

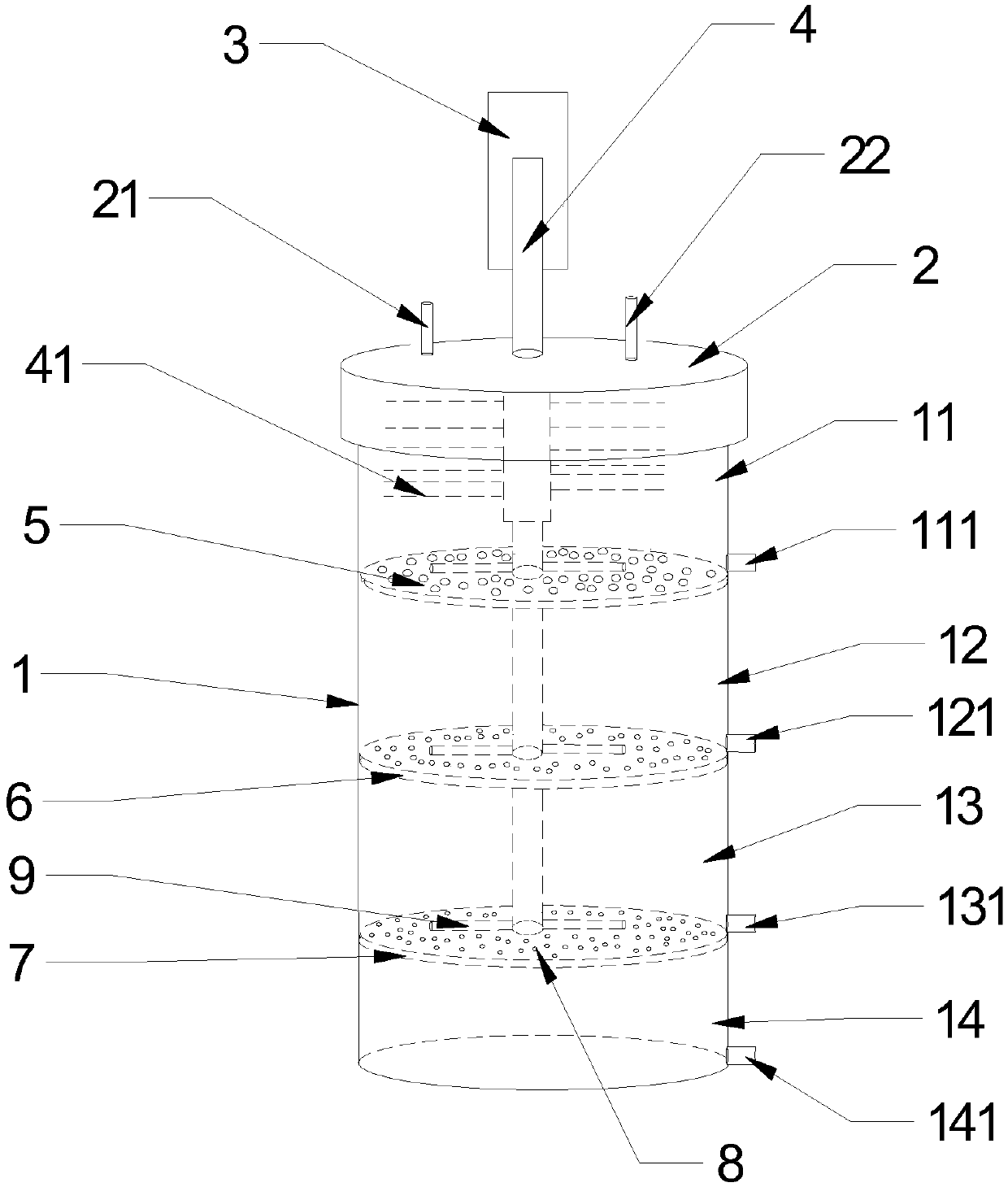

[0020] Such as figure 1 As shown, a fat particle separation and purification device disclosed in this embodiment includes a cylinder 1 and a cover 2. The cover 2 is closed on the top of the cylinder 1 to form a fully-sealed fat storage tank. The cover 2 is provided with a negative Pressure port 21 and fat suction port 22, three filters 5, 6 and 7 are arranged inside the cylinder body 2, and the three filters 5, 6 and 7 divide the cylinder body into four separation chambers 11 from top to bottom in the cylinder body , 12, 13 and 14, the separation chamber 11 that is positioned at the uppermost floor is a sample collection chamber, and the separation chamber 14 that is positioned at the bottom floor is a waste collection chamber, and a rotating shaft 4 is arranged in the middle part of the cover body 2, and the top of the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com