Flexible guardrail and rubber sponge body composition and production technology applied to flexible guardrail

A technology of rubber sponge and flexible guardrail, applied in construction, road, road safety devices, etc., can solve problems such as poor ability of guardrail to absorb impact force, car overturning, steering, retrograde, secondary traffic accident, etc. The effect of preventing the car from overturning, reducing the degree of danger, and improving the buffer capacity and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

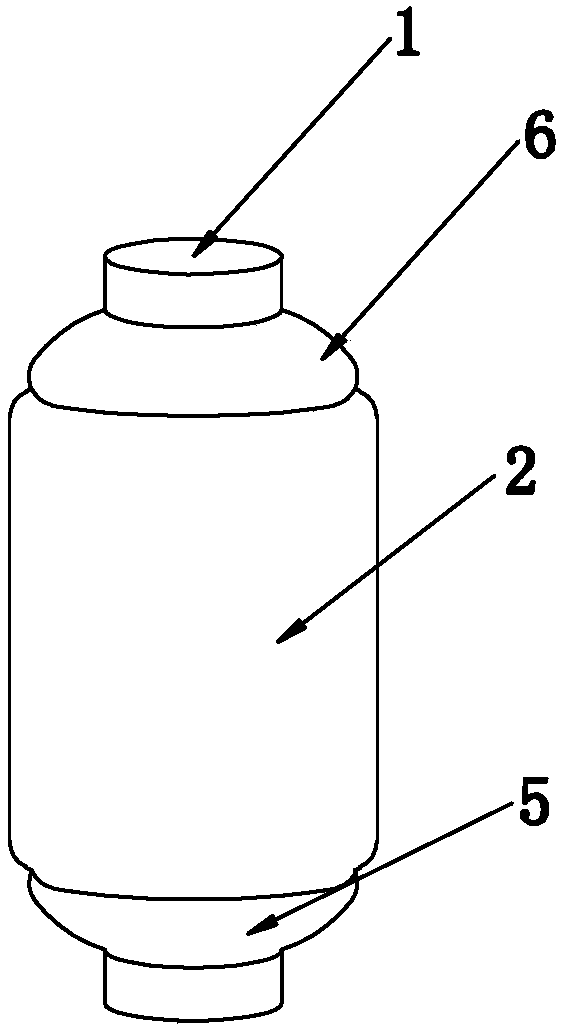

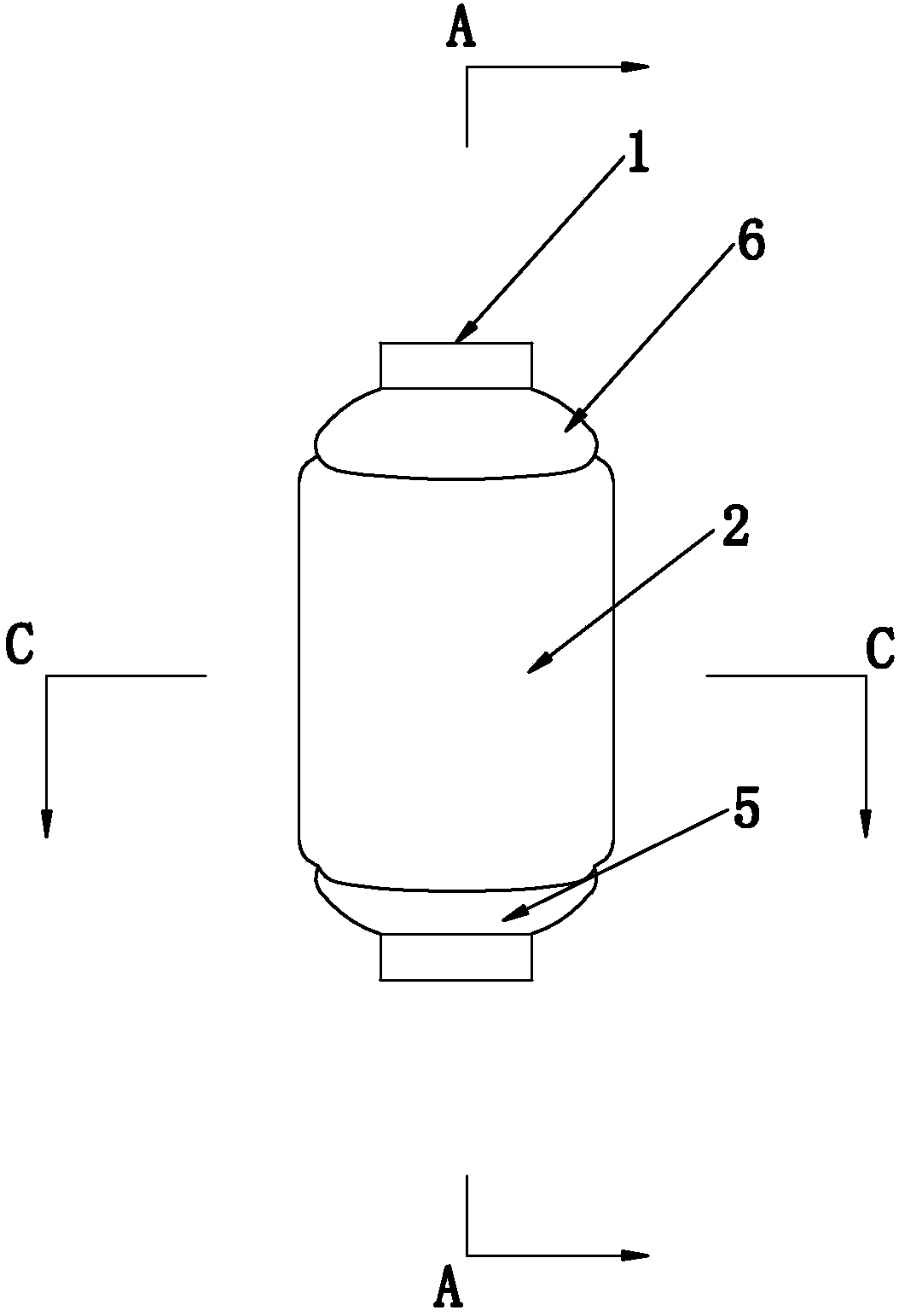

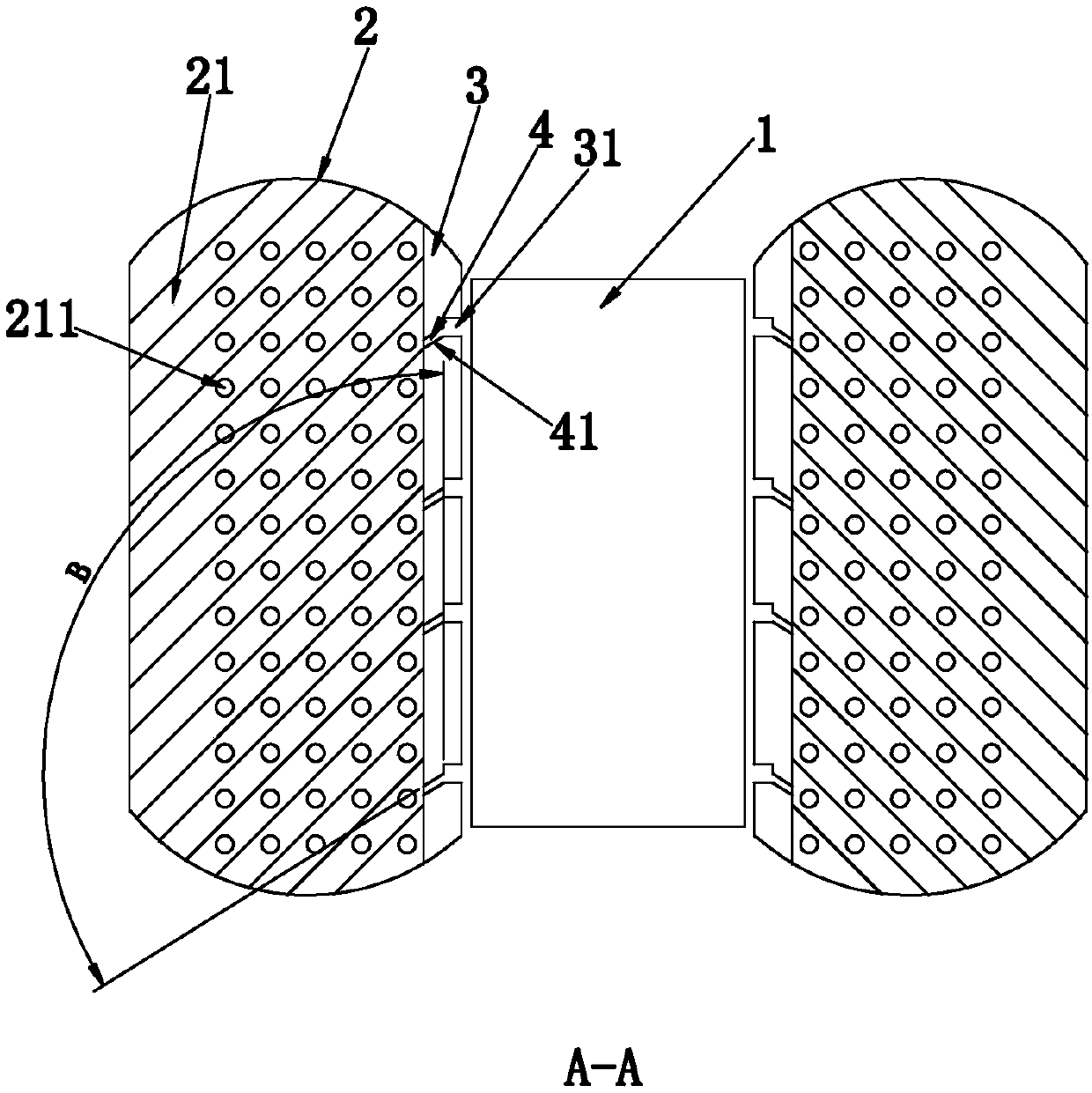

[0039] Such as Figure 1~Figure 5 As shown, the present invention discloses a process formula of a flexible guardrail and a rubber sponge body and its manufacturing technology. In a specific embodiment of the present invention, a column 1 is included, and the outer wall of the column 1 is covered with a PVC sleeve 3 for dynamic fit. , the outer wall of the PVC sleeve 3 is wrapped with a rubber sponge body 2, the rubber sponge body 2 is statically matched with the outer wall of the PVC sleeve 3, and the airflow guiding device 4 is arranged inside the rubber sponge body 2.

[0040] In a specific embodiment of the present invention, the rubber sponge 2 includes a rubber strip 21 with at least one layer of independent air holes 211 wound on the outer wall of the column 1, and four air strips are arranged on the inner wall of the PVC sleeve 3. Guide groove 31.

[0041] In a specific embodiment of the present invention, the independent pores 211 of each layer may communicate with e...

Embodiment 2

[0052] A kind of technological formula of rubber sponge body, the component in the specific embodiment of the present invention is as follows,

[0053] Its components are proportioned by mass as follows: 100 parts of NR rubber, 20 parts of carbon black filler, 4 parts of zinc oxide, 2 parts of stearic acid, 25 parts of softener, 4 parts of anti-aging agent, 3 parts of sulfur, 3 parts of accelerator , 3 parts of anti-ultraviolet special additives, 4 parts of foaming agent.

[0054] A kind of manufacturing technology of rubber sponge, in the specific embodiment of the present invention,

[0055] Material mixing: add the above materials into the mixing equipment for mixing;

[0056] Material extrusion: Put the mixed material into the ø250 extruder, and continuously extrude unvulcanized rubber strips with a thickness of 6~10mm through the ø250 extruder;

[0057] Initial molding: wind the unvulcanized rubber strip on a ø200 molding machine to make a rubber sponge, and put the rub...

Embodiment 3

[0062] A kind of technological formula of rubber sponge body, the component in the specific embodiment of the present invention is as follows,

[0063] Its components are proportioned by mass as follows: 100 parts of CM / RR rubber, 20 parts of carbon black filler, 4 parts of zinc oxide, 3 parts of stearic acid, 25 parts of softener, 6 parts of anti-aging agent, 3 parts of sulfur, 6 parts Accelerator, 2 parts of anti-ultraviolet special auxiliary agent, 2 parts of foaming agent.

[0064] A kind of manufacturing technology of rubber sponge, in the specific embodiment of the present invention,

[0065] Material mixing: add the above materials into the mixing equipment for mixing;

[0066] Material extrusion: put the mixed material into the ø250 extruder, and continuously extrude unvulcanized rubber strips with a thickness of 30mm through the ø250 extruder;

[0067] Initial molding: wind the unvulcanized rubber strip on a ø200 molding machine to make a rubber sponge, and put the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com