A pile foundation construction method for crossing fully-filled karst caves

A construction method and full filling technology, which can be used in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of wasting manpower, material resources and financial resources, buried drilling, leakage of conduit joints, etc., and improve the quality and speed of pile formation. , The effect of enhancing the integrity and impact resistance, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to enable those skilled in the art to better understand, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

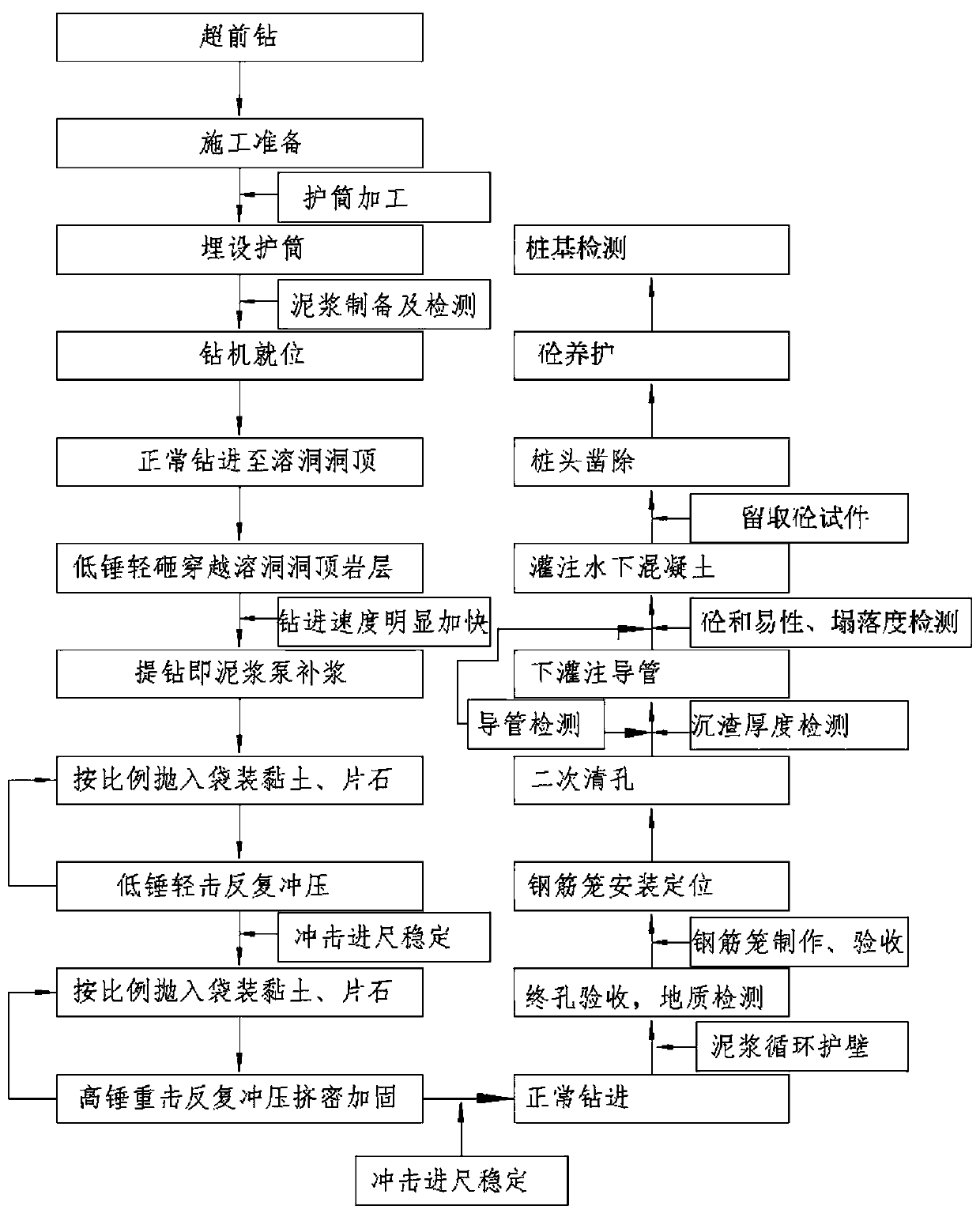

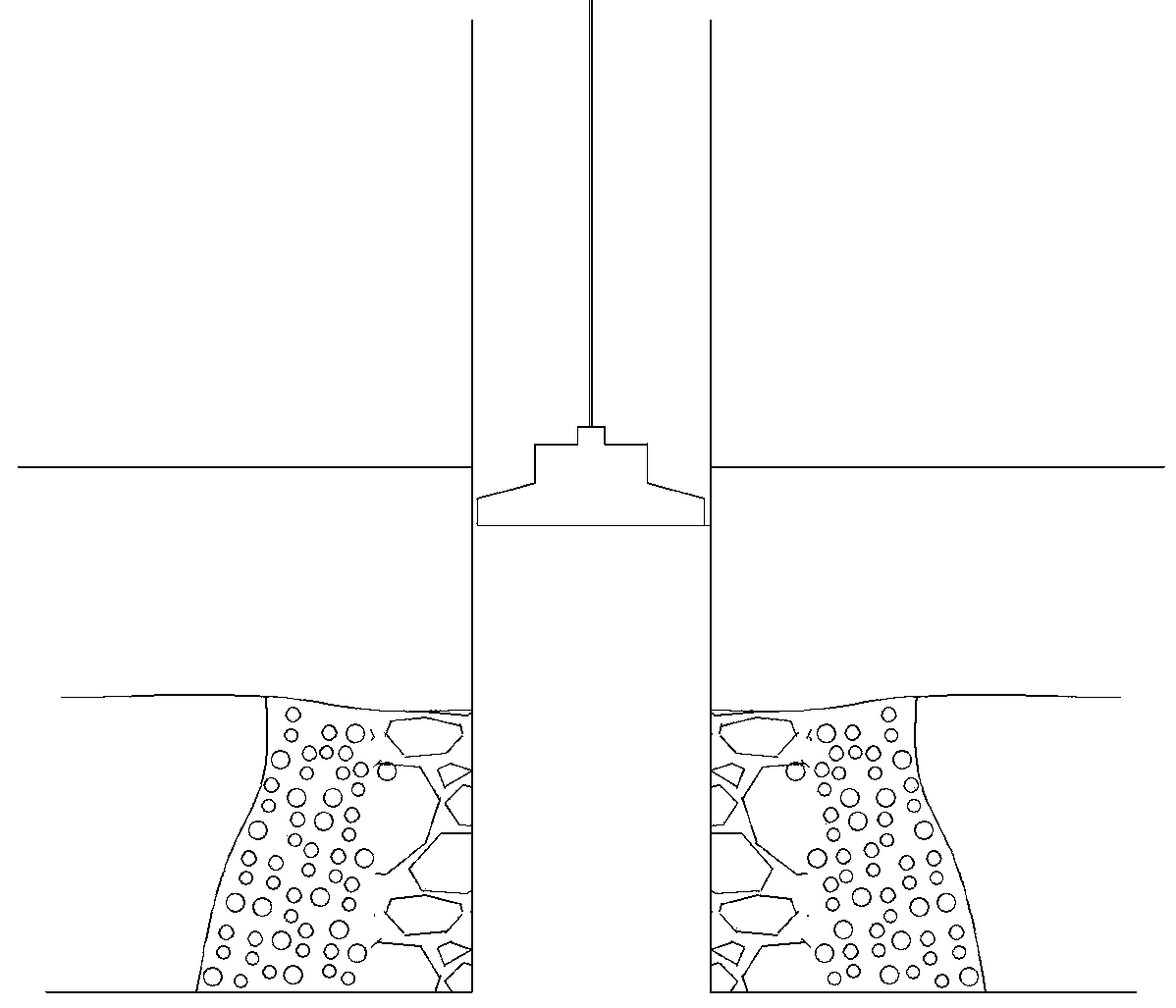

[0053] like figure 1 , figure 2 , image 3 A pile foundation construction method for crossing a fully filled karst cave is shown, comprising the following steps:

[0054] Step 1. Advanced drilling: For the area where the geological survey reveals the development of karst caves, advanced drilling is carried out before the pile foundation construction and the properties of the bedrock are identified. It is required to check the geological age, layer number, layer bottom elevation, and classification Layer thickness, stratum properties, strength of rock samples, presence or absence of karst caves, size of karst caves, roof thickness of karst caves, and degree of roof fragmentation are described in detail, and a columnar diagram of boreholes, a detailed map of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com