Environment-friendly river and lake contaminated sediment dredging and solidifying continuous processing method

A technology for polluted sediment and environmental dredging, which is applied in sludge treatment, water/sludge/sewage treatment, fixed/solidified sludge treatment, etc. The effect of reducing the amount of civil engineering, reducing the occupied space and increasing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

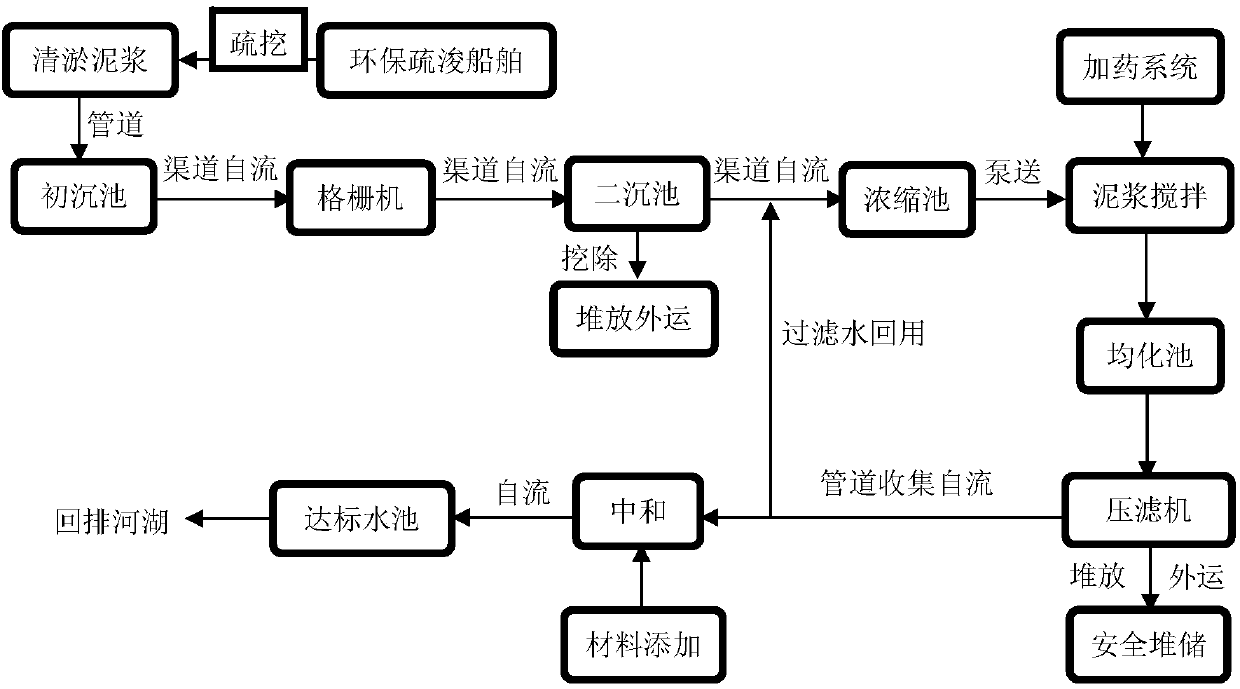

[0033] A continuous treatment method for environmentally friendly dredging and solidification of polluted river and lake sediments, including dredging, transportation, volume reduction, solidification, and continuous storage of polluted sediments, and the combination of dredging, transportation, volume reduction, solidification, and storage As a complete disposal system, the dredging of contaminated sediment is carried out through transportation, volume reduction and solidification, the solidified soil is stored, and the liquid is reused or drained back to achieve continuous treatment in a closed assembly line.

[0034] The dredging of contaminated sediment is directly transported by pipeline, and the suction and discharge of sludge are completed at one time. When there is insufficient discharge pressure, a relay pump station is added to the pipeline. The dredging cutter head is equipped with reamer depth positioning and ship plane positioning devices, and the reamer is equippe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap