Engine ultra-high compression ratio combustion control device and method based on jet ignition

A technology of engine and compression ratio, which is applied in the direction of engine control, engine operation, engine components, etc., can solve the problems of reducing flame propagation speed and stability, and achieve the effects of lowering temperature, easy modification, and low NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below with reference to the accompanying drawings and examples.

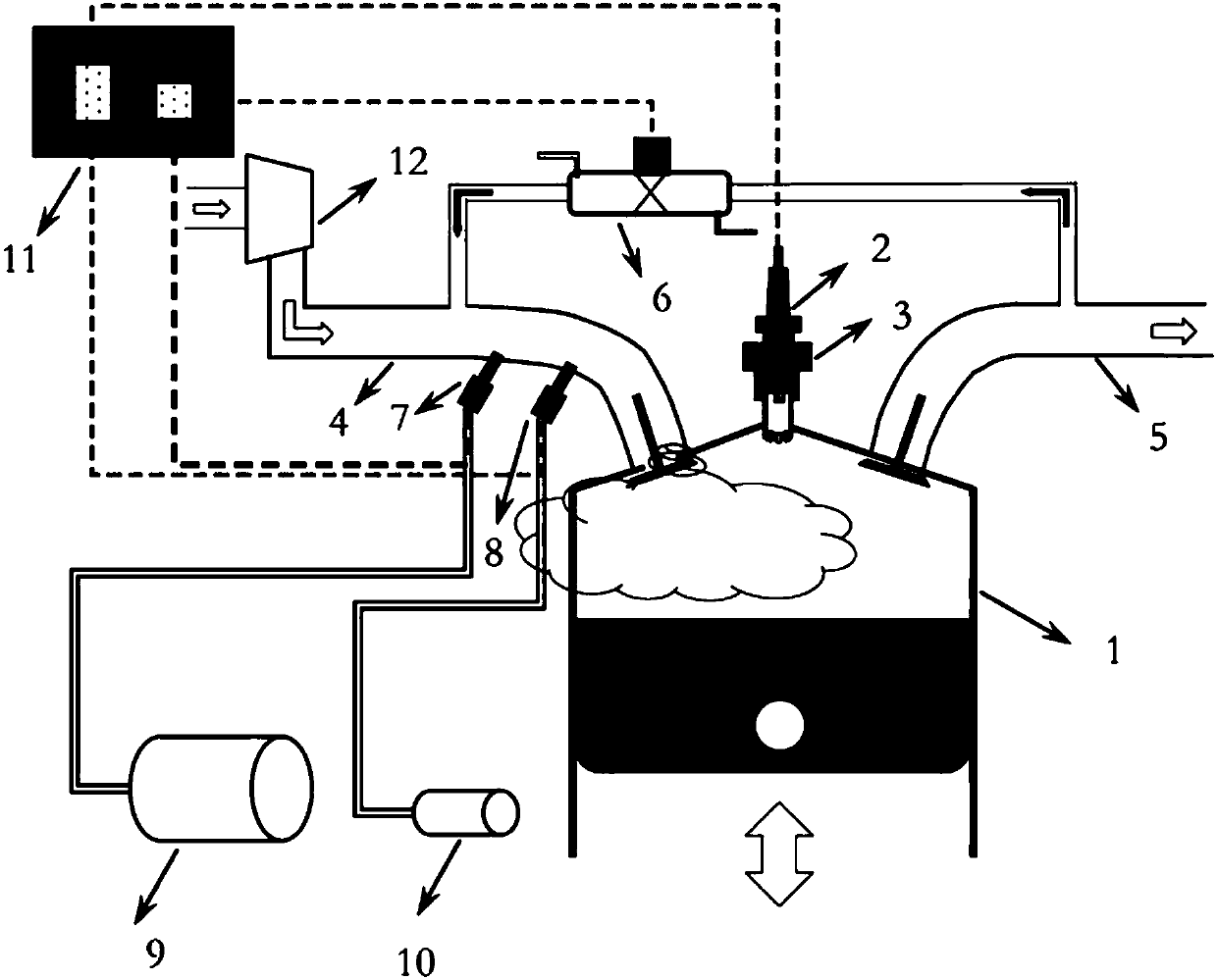

[0040] The present invention provides an engine ultra-high compression ratio combustion control scheme based on spark plug pre-chamber jet ignition, which utilizes hydrogen doping, large EGR, supercharger and is equipped with spark plug pre-chamber, and finally obtains ultra-high engine thermal efficiency.

[0041] The spark plug pre-chamber can greatly increase the combustion rate and improve combustion stability. It is by installing a portable pre-chamber with a volume of only 1-2ml at the front of the ignition engine spark plug. The spark plug pre-chamber is connected to the combustion chamber with multiple nozzle holes. The thread size of the spark plug pre-chamber connected to the combustion chamber is the same as The spark plugs are the same, so they can be installed directly, no modification of the engine is required, and the cost is extremely low. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com