LNG cold energy gradient utilization method for recovering light hydrocarbon by adopting cold energy

A light hydrocarbon recovery and cold energy technology, which is applied in the direction of cold treatment separation, refrigeration and liquefaction, liquefaction, etc., can solve the problems of unreasonable utilization of cold energy, reduced effect of cold energy utilization, and large losses, so as to improve energy utilization efficiency, The effect of improving the recovery rate of cooling capacity and reducing the cost of vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

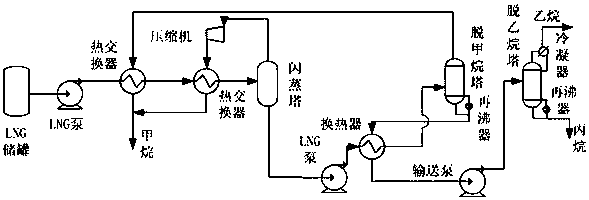

[0062] Such as Figure 8 Shown, adopt the LNG cold energy cascade utilization method of cold energy light hydrocarbon recovery, it comprises the following steps:

[0063] S1. Use LNG cold energy to recover light hydrocarbons;

[0064] S2. Use the LNG cold energy after light hydrocarbon recovery to carry out low-temperature crushing of waste rubber;

[0065] S3. Utilize the cold energy of LNG after the waste rubber is pulverized at low temperature to cool the warehouse.

[0066] According to the thermodynamic calculation method, the process The loss calculation process is as follows:

[0067] ex stands for single stage process EX stands for total plan

[0068] pressure ex p =T 0 RIn(p / p 0 ),

[0069] sensible heat cold ex c,s = c p (T-T 0 )+c p T 0 ln(T 0 / T)

[0070] latent heat cold

[0071] ex=ex p +ex c,s +ex c,l .

[0072] ① Light hydrocarbon recovery

[0073] ex p =-161.5kJ / kg; ex c,s =53.5kJ / kg; ex c,l =373.1kJ / kg; ex=265.0kJ / kg

[0...

Embodiment 2

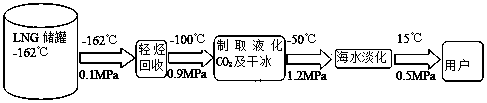

[0080] Such as Figure 9 Shown, adopt the LNG cold energy cascade utilization method of cold energy light hydrocarbon recovery, it comprises the following steps:

[0081] S1. Use LNG cold energy to recover light hydrocarbons;

[0082] S2. Use the LNG cold energy after light hydrocarbon recovery to carry out low-temperature crushing of waste rubber;

[0083] S3. Seawater desalination is carried out by utilizing the cold energy of LNG after the waste rubber is pulverized at low temperature.

[0084] ① Light hydrocarbon recovery

[0085] ex p =-161.5kJ / kg; ex c,s =53.5kJ / kg; ex c,l =373.1kJ / kg; ex=265.0kJ / kg

[0086] ②Crush waste rubber at low temperature

[0087] ex p =-103.8kJ / kg; ex c,s =6.5kJ / kg; ex c,l =91.6kJ / kg; ex=-5.7kJ / kg

[0088] ③ Sea water desalination

[0089] ex p =131.1kJ / kg; ex c,s = 15.7kJ / kg; ex c,l =132.9kJ / kg; ex=279.7kJ / kg

[0090] EX=539kJ / kg

Embodiment 3

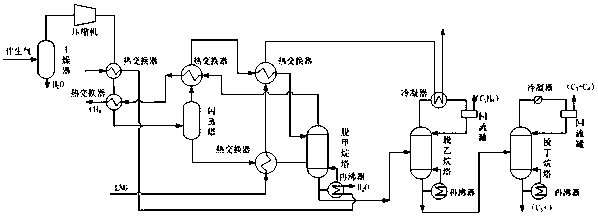

[0092] Such as Figure 10 Shown, adopt the LNG cold energy cascade utilization method of cold energy light hydrocarbon recovery, it comprises the following steps:

[0093] S1. Use LNG cold energy to recover light hydrocarbons;

[0094] S2. Utilize the cold energy of LNG after the recovery of light hydrocarbons to produce liquefied CO 2 and dry ice;

[0095] S3. Utilization is completed to produce liquefied CO 2 And LNG cold energy after dry ice for warehouse refrigeration.

[0096] ① Light hydrocarbon recovery

[0097] ex p =-197.7kJ / kg; ex c,s =31.9kJ / kg; ex c,l =282.1kJ / kg; ex=116.3kJ / kg

[0098] ② Preparation of liquefied carbon dioxide and dry ice

[0099] ex p =30.4kJ / kg; ex c,s =20.3kJ / kg; ex c,l =175.1kJ / kg; ex=225.8kJ / kg

[0100] ③Frozen warehouse

[0101] ex p =50.4kJ / kg; ex c,s =13.0kJ / kg; ex c,l =119.2kJ / kg; ex=182.6kJ / kg

[0102] EX=524.7kJ / kg

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com