Ag/AgCl reference electrode (RE) and manufacturing method thereof

A technology of silver chloride electrode and reference electrode, which is applied in the field of sensors, can solve the problems that the sensor cannot work continuously for a long time, the service life of the electrode is not long, and the application of the sensor is limited, so as to achieve good consistency, increase the use time, and reduce the cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

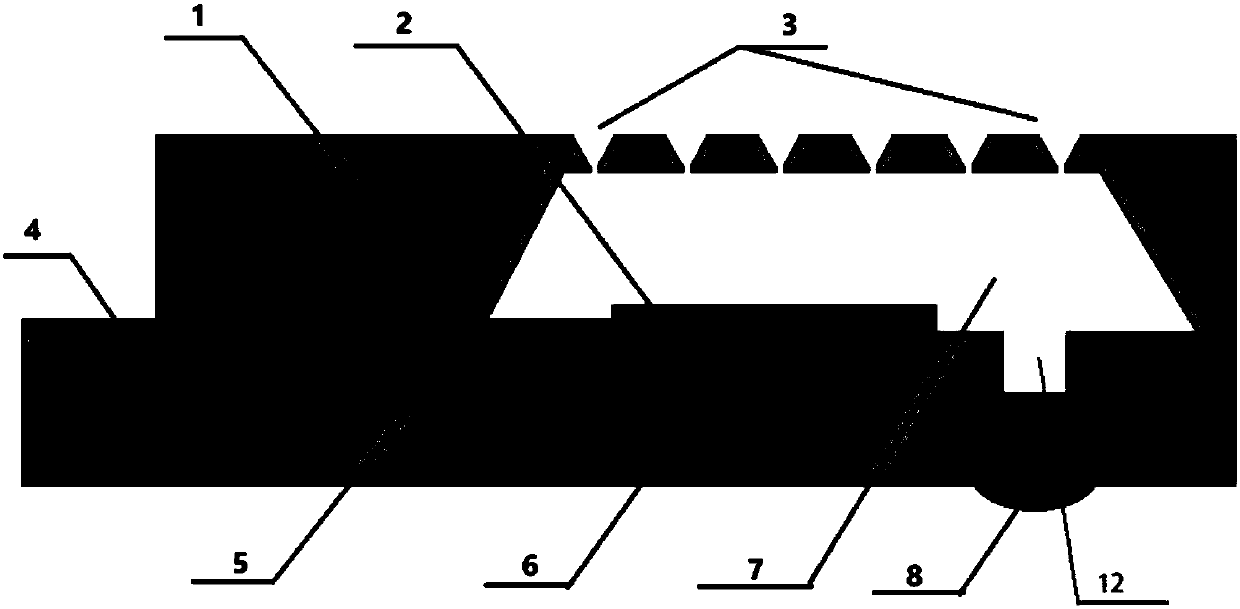

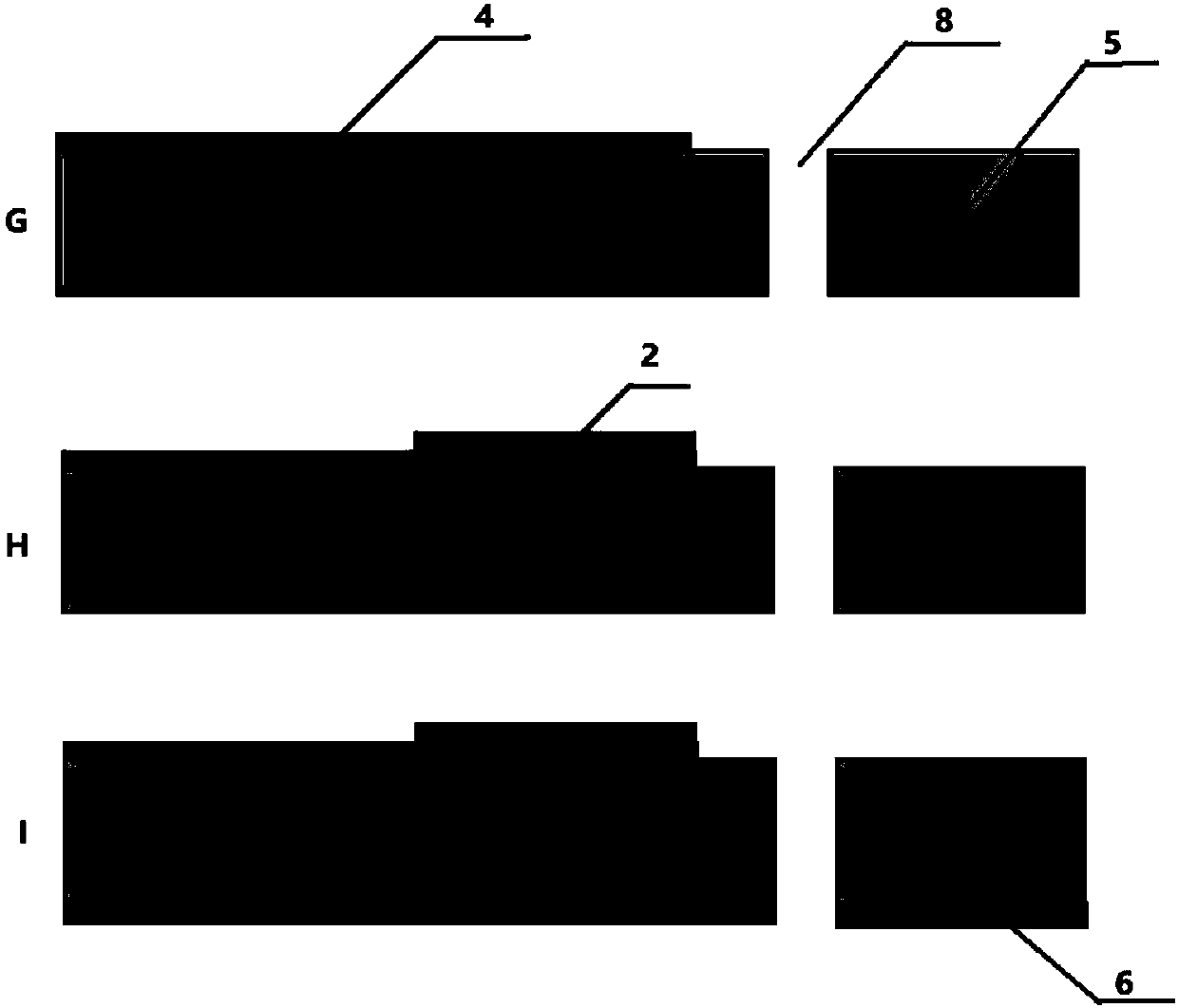

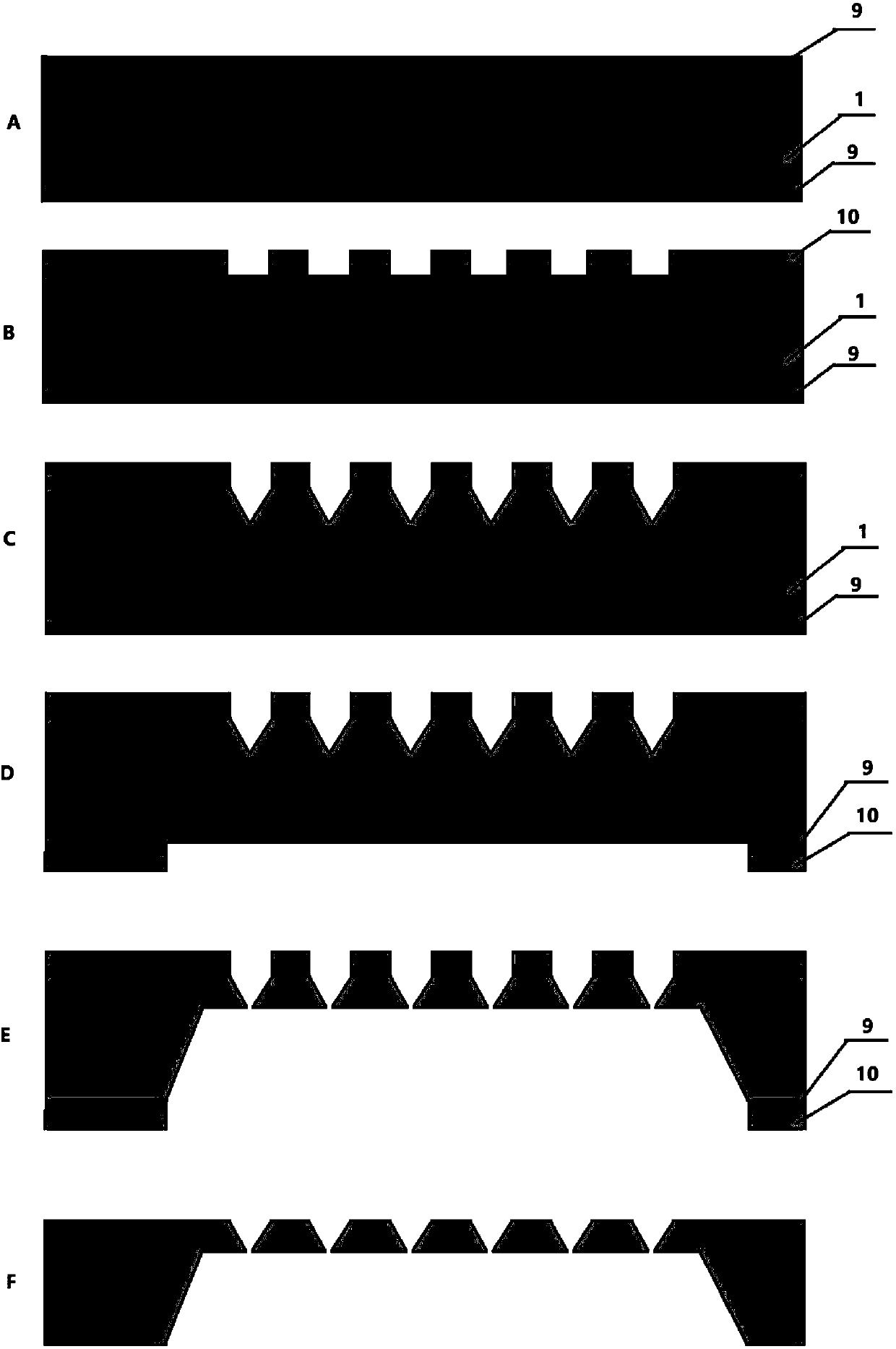

[0035] The silver / silver chloride reference electrode of the present invention, such as figure 1 As shown, it includes a Pyrex 7740 glass substrate 5 that can be bonded to a silicon chip. The upper surface of the glass substrate 5 is provided with a platinum electrode lead 4, and a silver / silver chloride electrode layer is provided on the upper surface of the end section of the platinum electrode lead 4. 2. The glass substrate 5 is covered with a (100) crystal surface, double-sided polished and oxidized silicon substrate 1 in a bonded manner, and the two are bonded to form one body; the silicon substrate 1 is provided with a downward opening At least the cavity containing the silver / silver chloride electrode layer 2 forms a liquid storage chamber 7 for storing potassium chloride saturated solution with the glass substrate 5. A nano-scale tape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com