Driving mechanism for reactor control rod of nuclear power plant

A technology for a nuclear power plant reactor and driving mechanism, which is applied in the control of nuclear reactions, reactors, nuclear power generation, etc., can solve the problems of low measurement accuracy of single-precision rod position detectors, poor temperature resistance of coil materials, and failure to meet single-fault criteria, etc. Achieve the effect of increasing redundant design, reducing operating current, and improving measurement accuracy and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the purpose, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

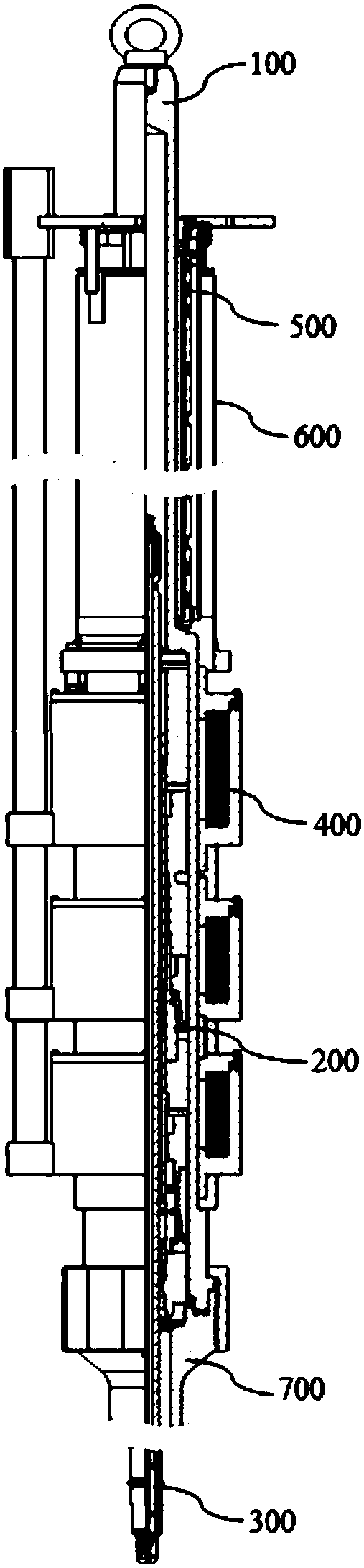

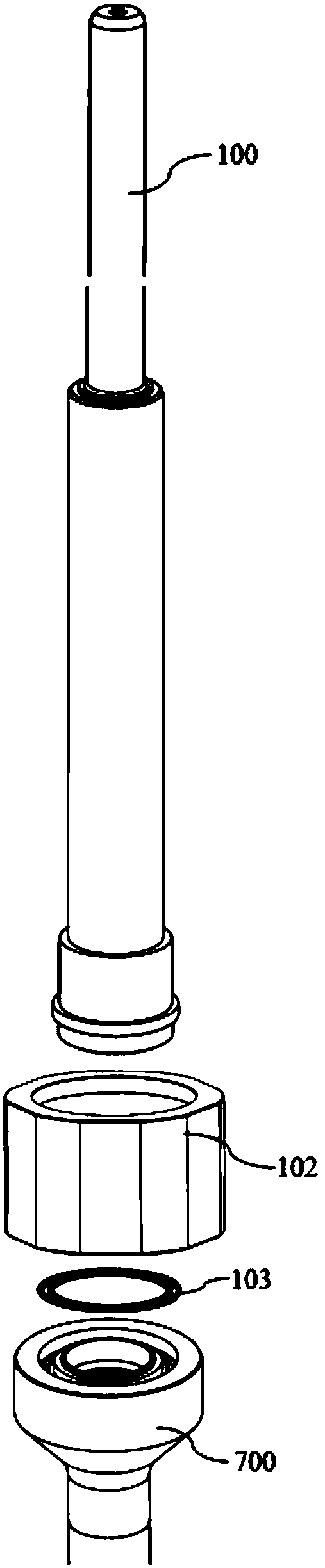

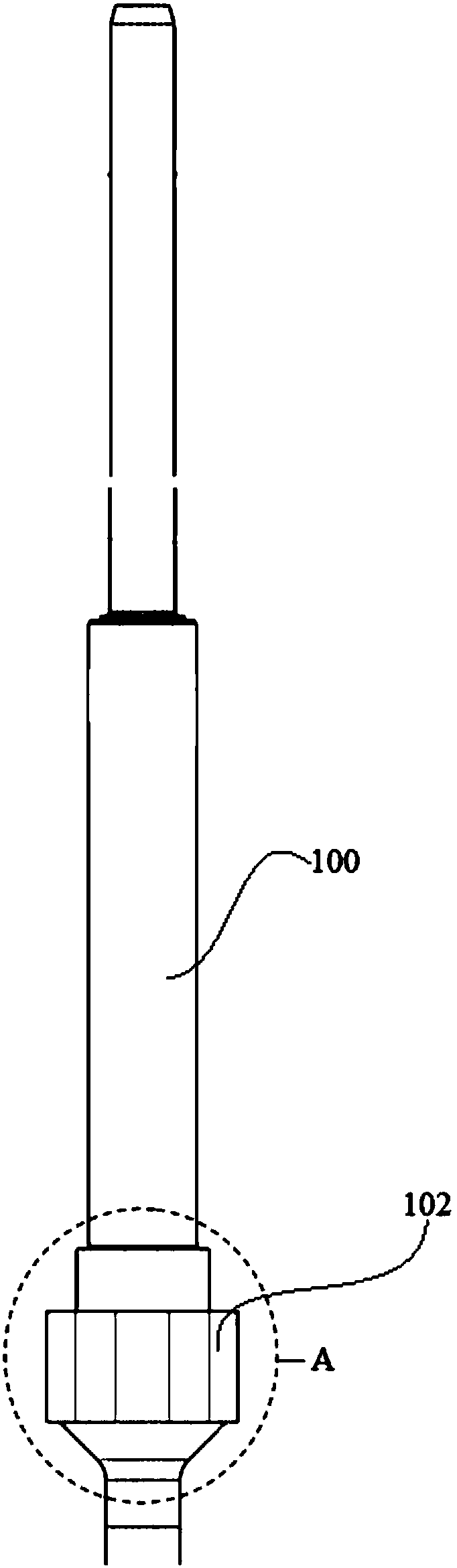

[0056] Please refer to Figures 1 to 10 As shown, the nuclear power plant reactor control rod driving mechanism of the present invention includes a pressure casing assembly 100, a claw assembly 200, a driving rod assembly 300, a coil assembly 400 and a rod position detector assembly 500, wherein the pressure casing assembly 100 is an integrated casing Body, the top is a blind pipe structure, and the bottom is detachably sealed and installed on the CRDM pipe seat of the pressure vessel top cover through a threaded connection.

[0057] Please refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com