Base film layer structure used for lithium ion battery and preparation method

A lithium-ion battery and layer structure technology, which is applied to structural parts, battery pack parts, circuits, etc., can solve the problems of increasing the production cost of lithium batteries, lack of flame-retardant components, high cost of copper foil, etc., to prevent power shortage , The preparation method is scientific and reasonable, and the effect of enhancing the permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

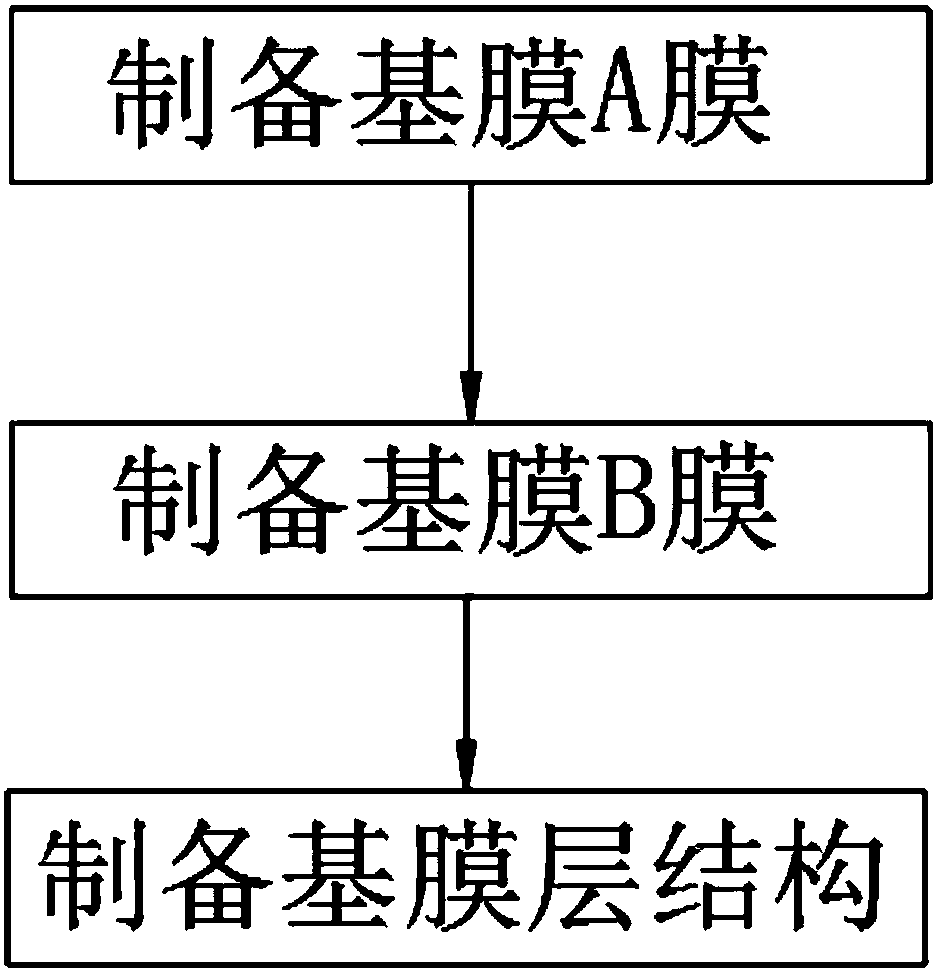

[0020] Embodiment 1: as figure 1 As shown, the present invention provides a kind of base film layer structure for lithium ion battery, and described base film layer structure comprises base film A film and base film B film, and described base film A film is made of norbornene copolymer, PC, EVA And the monolayer structure composed of filler or norbornene copolymer, POE, EVA and filler or norbornene copolymer, PP, EVA and filler or norbornene copolymer and PET and filler, the base Film B film includes base layer, shock-absorbing diaphragm bubble, woven film, microporous film, antistatic particles, rolling film, resin film, non-woven film, aluminum shell film layer, PP film layer and PE film layer. The upper part is provided with a shock-absorbing diaphragm bubble, and the bottom end of the shock-absorbing diaphragm bubble is provided with a woven membrane. The bottom end of the woven membrane is equipped with a microporous membrane, and antistatic particles are embedded in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com