Intermediate-infrared solid laser

A solid-state laser and laser technology, applied in the field of laser, can solve the problems that the solid medium cannot be effectively guaranteed not to deform, the power of the mid-infrared laser is low, and the adjustment range is limited, and the structure is simple, the light energy utilization rate is high, and the structure is simplified. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

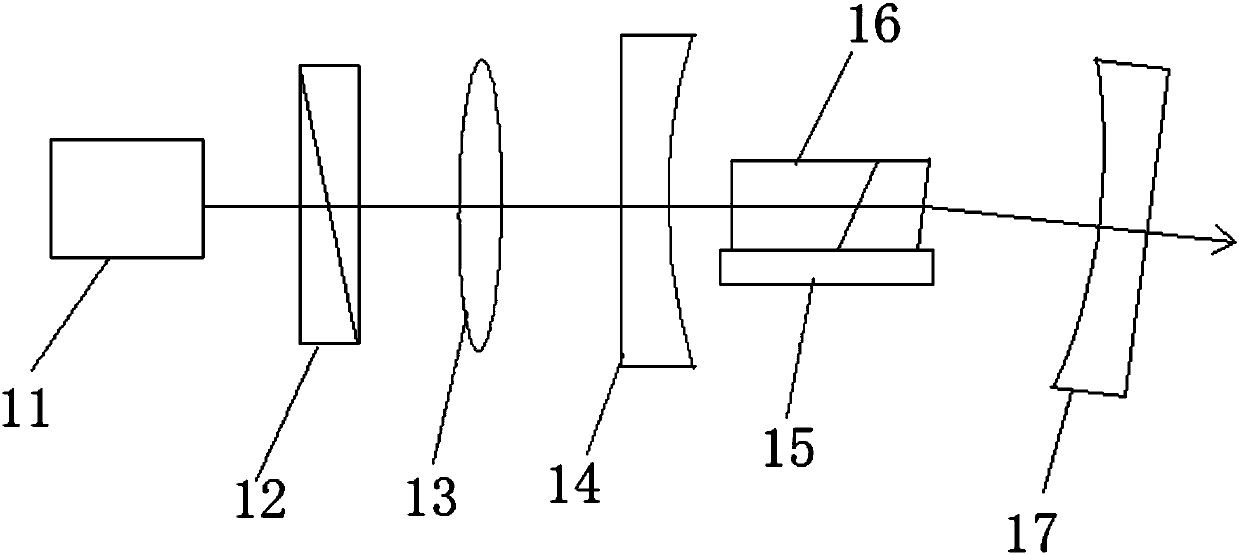

[0028] Wherein, the resonant cavity is made up of two oppositely arranged concave mirrors (14, 17), one concave mirror 14 is used as an input mirror, the other concave mirror 17 is used as an output mirror, and the concave surface of the concave mirror 14 as the input mirror is coated with an anti-reflection film And high reflection film, the concave surface of the concave mirror 17 as output mirror is coated with high reflection film. For example, in one embodiment, the concave surface of the concave mirror 14 as the input mirror is coated with an anti-reflection coating with a central wavelength of 790nm and a transmittance greater than 99.5%, and a high-reflective coating with a central wavelength of 1900nm and 2400nm and a reflectivity greater than 99.5%; The concave surface coating 17 of the concave mirror as the output mirror has a high reflection film with a central wavelength of 2400nm and a reflectivity greater than 95%, and a high reflective film with a central wavele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Center wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com