Dust suction type casting float polishing mechanism

A grinding mechanism and dust-absorbing technology, which is applied in the field of mechanical devices, can solve problems such as the harsh environment of the grinding site, the impact on the health of the grinder, and damage to the grinding wheel castings, and achieve the effects of simple structure, balanced impact, and improved grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

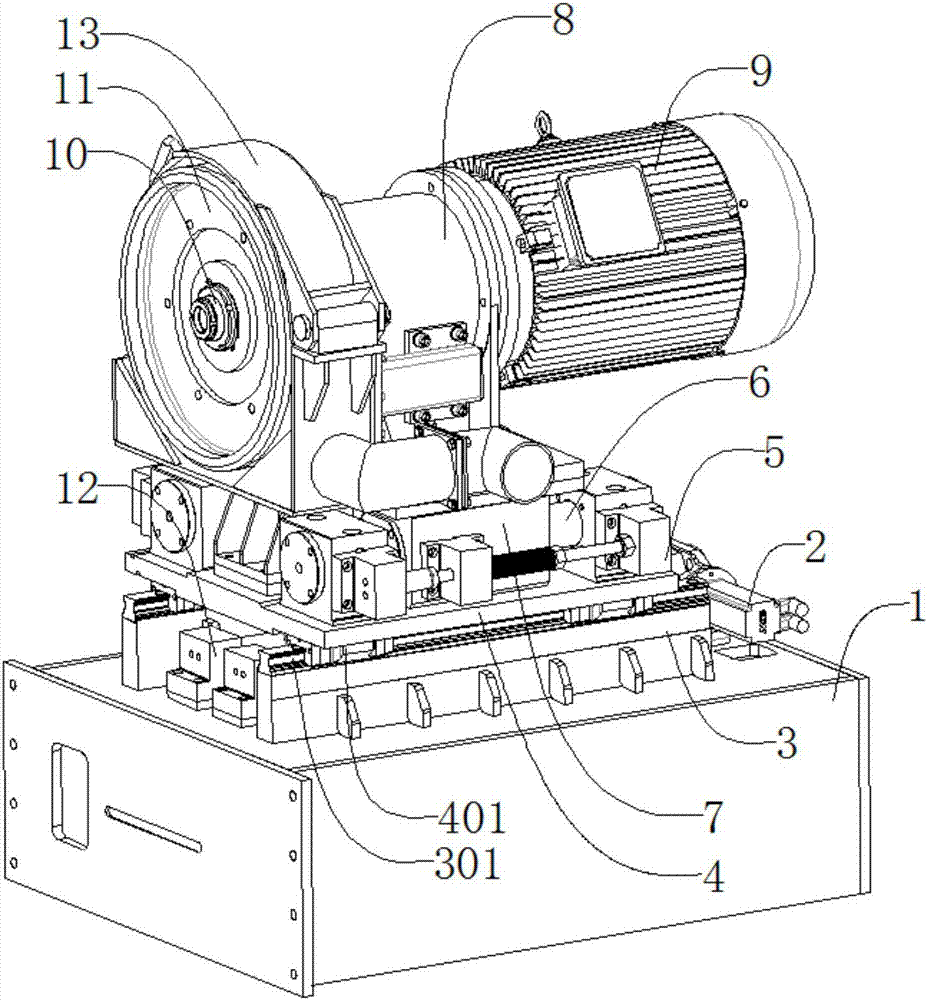

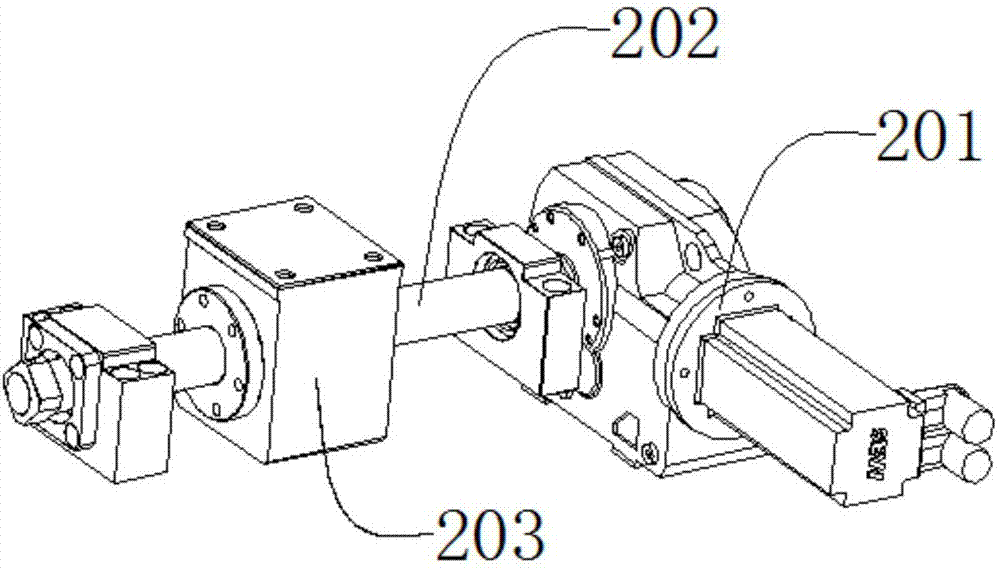

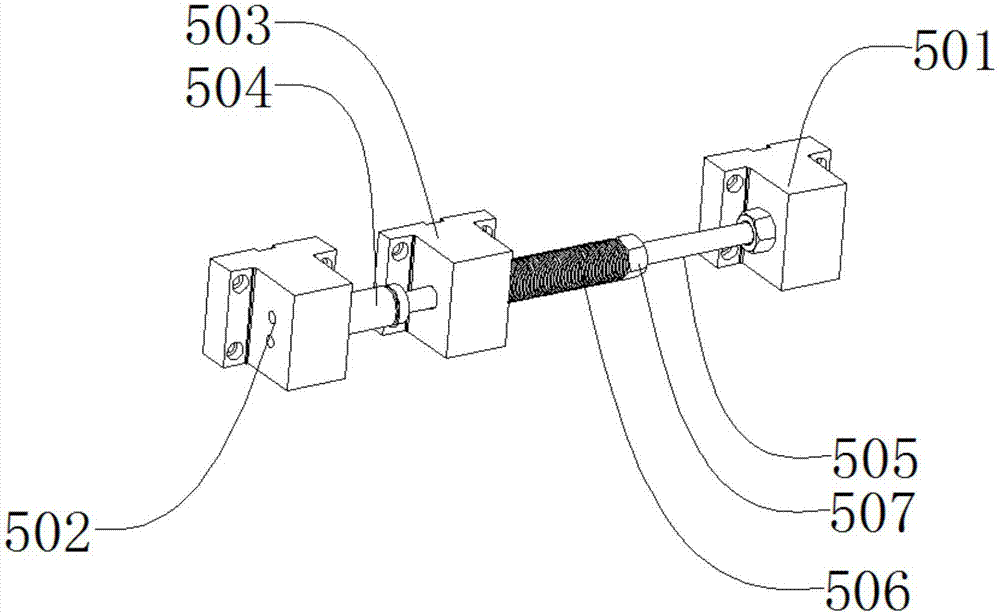

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, a dust-absorbing casting floating grinding mechanism includes a base 1, a feeding mechanism 2, a pad iron 3, a moving plate 4, an elastic mechanism 5, a first guide rod 6, a guide sleeve 7, a rotating shaft seat 8, and a motor 9 , rotating shaft 10, grinding wheel 11, first nitrogen gas spring 12, dust suction mechanism 13, described feed mechanism 2 is located at the upper end of base 1, described feed mechanism 2 is connected with base 1 by bolts, and described pad iron 3 The quantity is 2 pieces, arranged symmetrically front and back along the base 1, the moving plate 4 is located at the upper end of the pad iron 3 and at the upper end of the feeding mechanism 2, and the moving plate 4 can slide left and right along the pad iron 3, the described The moving plate 4 is connected with the feed mechanism 2 by bolts, the number of the elastic mechanisms 5 is 2 pieces, and they are symmetrically arranged along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com