Nanometer antifogging film for fruits and vegetables and preparation method of nanometer antifogging film

An anti-fog film, fruit and vegetable technology, applied in the field of preparation of nanometer fruit and vegetable anti-fog film, can solve the problems of reducing the use efficiency of the anti-fog film, the loss of anti-fog droplets, the failure of the anti-fog film, etc., and achieves good anti-fog effect and maintenance. Anti-fog properties and the effect of reducing the rate of decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: 10g nano-titanium dioxide is added in the blend of 100g SPAN-20 and 100g TWEEN-20, is placed in the ultrasonic disperser and disperses 1h, after the mixture and 790gLDPE resin are mixed homogeneously in the high-speed mixer, then Extrude and granulate through a twin-screw extruder with a screw diameter of 21.7mm and an aspect ratio of 40. The screw speed is 600rpm. The five-stage temperature from the feed end to the die head is 158°C, 160°C, 165°C, and 165°C. At 170°C, the resulting masterbatch and LDPE resin were granulated at a ratio of 1:9. Weigh 2g of masterbatch, press it between the flat plates loaded with polyimide film, and then place it on the abutment of the flat vulcanizer. The temperature of the upper mold and the middle mold are selected at 170°C. After 15 minutes, the masterbatch melts and the film is pressed. 5min, take it out and anneal for 15min, after cooling, peel off the film for use.

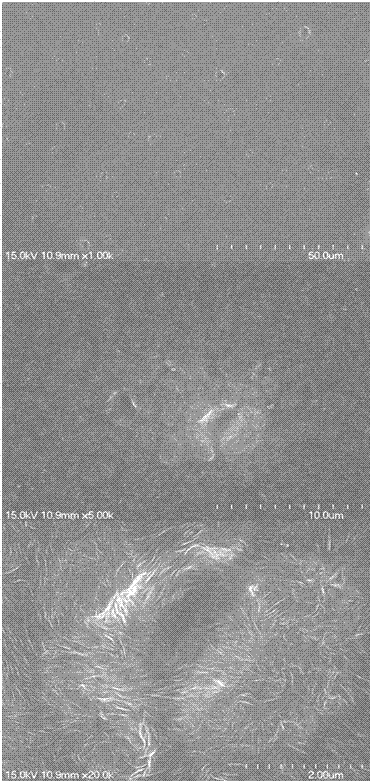

[0035] figure 1 From top to bottom are scanning ...

Embodiment 2

[0037] Embodiment 2: 20g nano-titanium dioxide is added in the blend of 50g SPAN-20 and 150g TWEEN-20, is placed in ultrasonic disperser and disperses 1h, after the mixture and 780gLDPE resin are mixed homogeneously in high-speed mixer, then Extrude and granulate through a twin-screw extruder with a screw diameter of 21.7mm and an aspect ratio of 40. The screw speed is 600rpm. The five-stage temperature from the feed end to the die head is 158°C, 160°C, 165°C, and 165°C. At 170°C, the obtained masterbatch and LDPE resin are used for secondary granulation at a ratio of 1:10.

[0038] Weigh 2g of masterbatch, press it between the flat plates loaded with polyimide film, and then place it on the abutment of the flat vulcanizer. The temperature of the upper mold and the middle mold are selected at 140°C. After 20 minutes, the masterbatch melts and the film is pressed. 5min, take out and anneal for 15min, after cooling, peel off the film for use.

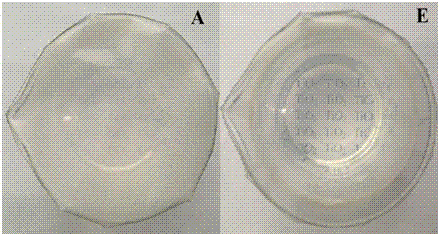

[0039] as shown in the picture ...

Embodiment 3

[0040] Embodiment 3: 10g nano-titanium dioxide is added in the blend of 150g SPAN-20 and 50g TWEEN-20, is placed in the ultrasonic disperser and disperses 1h, after the mixture and 790gLDPE resin are mixed homogeneously in the high-speed mixer, then Extrude and granulate through a twin-screw extruder with a screw diameter of 21.7mm and an aspect ratio of 40. The screw speed is 600rpm. The five-stage temperature from the feed end to the die head is 158°C, 160°C, 165°C, and 165°C. At 170°C, the obtained masterbatch and LDPE resin are used for secondary granulation at a ratio of 1:9. Weigh 2g of masterbatch, press it between the flat plates loaded with polyimide film, and then place it on the abutment of the flat vulcanizing machine. The temperature of the upper mold and the middle mold are selected at 170°C. After 20 minutes, the masterbatch melts and the film is pressed. 10min, take it out and anneal for 20min, after cooling, peel off the film for use.

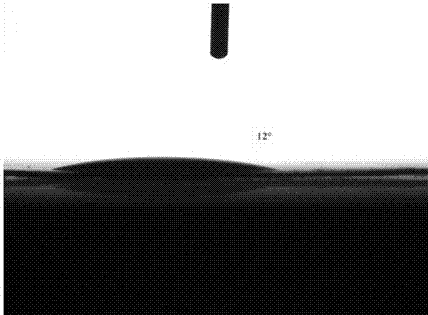

[0041] Such as Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com